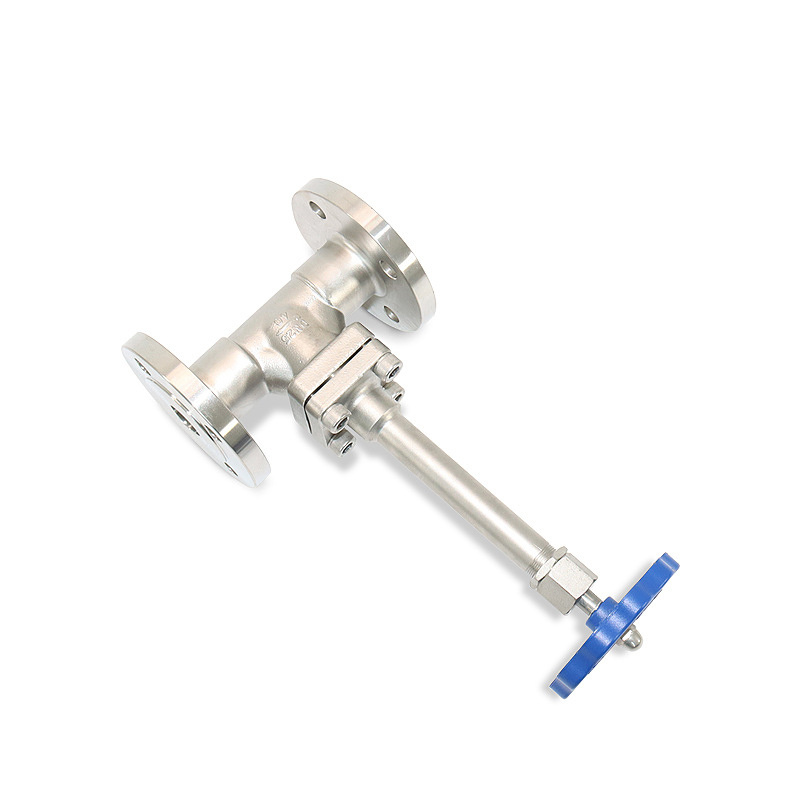

Cryogenic Globe Valve with flanged ends

Cryogenic Globe Valve with flanged ends: Overview, Structural Features & Technical Parameters

Cryogenic Globe Valves with flanged ends are generally installed at the liquid outlet and inlet of cryogenic storage tanks. They are mainly used in pipeline systems for cryogenic or normal-temperature media such as natural gas and LNG, featuring flexible opening and closing and reliable sealing. Their opening and closing element is a plug-shaped valve disc with a flat or conical sealing surface, and the valve disc moves linearly along the center line of the fluid.

Structural Features

The Cryogenic Globe Valve with flanged ends is equipped with an extended bonnet structure with sufficient air column length, ensuring that the temperature near the packing seal of the valve stem is not lower than 0℃. Specifically, after the cryogenic medium passes through the extended bonnet, the temperature gradually rises to the safe temperature required by the packing, thereby guaranteeing the reliability, safety, and integrity of the valve's packing seal.

The valve adopts a bolted bonnet, one-piece valve seat, replaceable PTFE/PCTFE gaskets, and stainless steel internal components. The valve base is designed with a conical shape for easy tight closing. The bolted bonnet is more convenient for maintenance, especially in narrow spaces, as the torque required for disassembly is much smaller than that of valves with one-piece bonnets of the same specification. Cryogenic Long-Stem Globe Valves with flanged ends are used at the liquid outlet and inlet of cryogenic storage tanks. Due to the extremely low temperature of the medium in the cryogenic storage tank, the temperature can easily transfer to the top of the handle in a short time. Therefore, cryogenic long-stem globe valves with flanged ends are adopted for pipelines in areas with large contact area with cryogenic liquids.

Technical Parameters

Product Name: Cryogenic Globe Valve with flanged ends

Valve Body Material: CF8

Connection Method: Flange Type

Working Pressure: 4.0MPa

Nominal Diameter: DN10~DN100

Actuation Method: Manual

Applicable Media: Gases and liquids such as LNG, LO2, LN2, LAr, CO2, etc.

Applicable Temperature: -196℃~+80℃

Bonnet Material: CF8

Valve Disc Seal: PTFE/PCTFE

Precautions

Oxygen service: oil-free (oil is prohibited for oxygen applications)

Manufacturing Standards

National Standard GB / Ministry of Machinery Industry Standard JB / Ministry of Chemical Industry Standard HG / American Standard ANSI/API / Japanese Standard JIS / German Standard DIN / Customization according to other standards