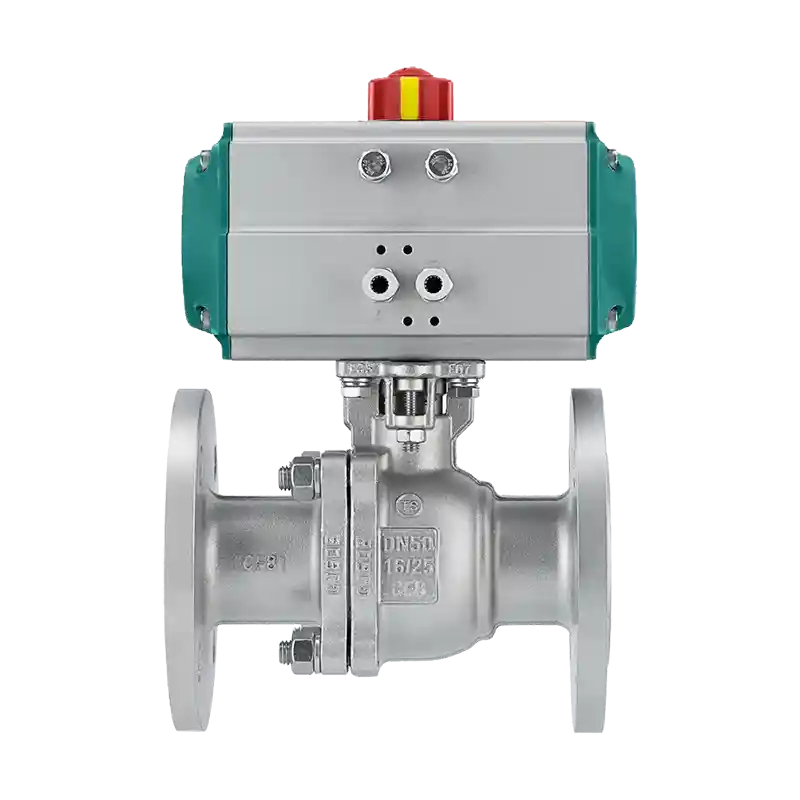

Pneumatic Metal Hard-Sealed Ball Valves

Pneumatic Metal Hard-Sealed Ball Valves

Pneumatic metal hard-sealed ball valves adopt new sealing materials for valve seats, which can increase the service life by 3~5 times compared with similar hard-sealed ball valve products. They have the advantages of stable performance, reliable sealing, low friction, easy opening and closing, high temperature resistance, wear resistance, oil resistance, corrosion resistance and long service life. They are mainly suitable for media such as high-temperature flue gas, engine exhaust gas and high-temperature mixed gas.

Working Principle

Pneumatic metal hard-sealed ball valves are composed of metal hard-sealed ball valves and piston-type pneumatic actuators. The sealing surface adopts metal hard-sealed valve seats, which can be applicable to media with temperature ≤ 350℃.

Pneumatic hard-sealed ball valves can be equipped with valve positioners and input control signals (4-20mADC or 1-5VDC) and air supply for controlled operation. Equipped with travel limit switches, solenoid valves, pressure reducing valves and 0.4~0.7MPa air supply, they can realize on-off operation and send out two pairs of passive contact signals to indicate the opening and closing status of the valves.

Overall, pneumatic hard-sealed ball valves have the advantages of compact structure, small size, reliable operation, good sealing performance, easy maintenance, convenient installation and strong adaptability. They are particularly suitable for occasions where the medium is viscous, particle-containing or fibrous.

Pneumatic high-temperature ball valves are widely used in industrial automatic control systems such as petroleum, chemical industry, teaching equipment, light industry, high-pressure equipment, pharmaceuticals and papermaking for remote centralized control or local control.

Technical Parameters

Parameter | Specifications |

Product Name | Pneumatic Metal Hard-Sealed Ball Valve |

Valve Body Material | Carbon Steel/Stainless Steel |

Connection Method | Flanged |

Applicable Pressure | 1.6MPa - 6.4MPa |

Nominal Diameter | DN15 ~ DN200 |

Actuation Method | Pneumatic |

Applicable Medium | High-temperature Flue Gas, Mixed Gas, Exhaust Gas, etc. |

Applicable Temperature | 350℃ |

Valve Core Material | 2Cr13, 304, 316, 316L |

Sealing Filler | Flexible Graphite Filler, etc. |

Leakage Rate | GB/T4213-92, less than 0.01% of rated KV |

Flow Characteristic | Approximate Quick-opening Type |

Actuator Type | AT Pneumatic Actuator |

Action Mode | Double-acting (Air Open & Air Close), Single-acting (Spring Return) |

Control Mode | On-off Two-position Control, 4-20mA Analog Control |

Air Supply Pressure | Double-acting: 3-8bar; Single-acting: 4-8bar |

Operating Medium | Air |

Connection Dimension | ISO5211 |

Air Supply Interface | Compliant with NAMUR Standard |

Manufacturing Standard | GB (National Standard)/JB (Mechanical Industry Standard)/HG (Chemical Industry Standard)/ANSI (American National Standard)/API (American Petroleum Institute)/JIS (Japanese Industrial Standard)/DIN (German Industrial Standard)/Customized Standards |