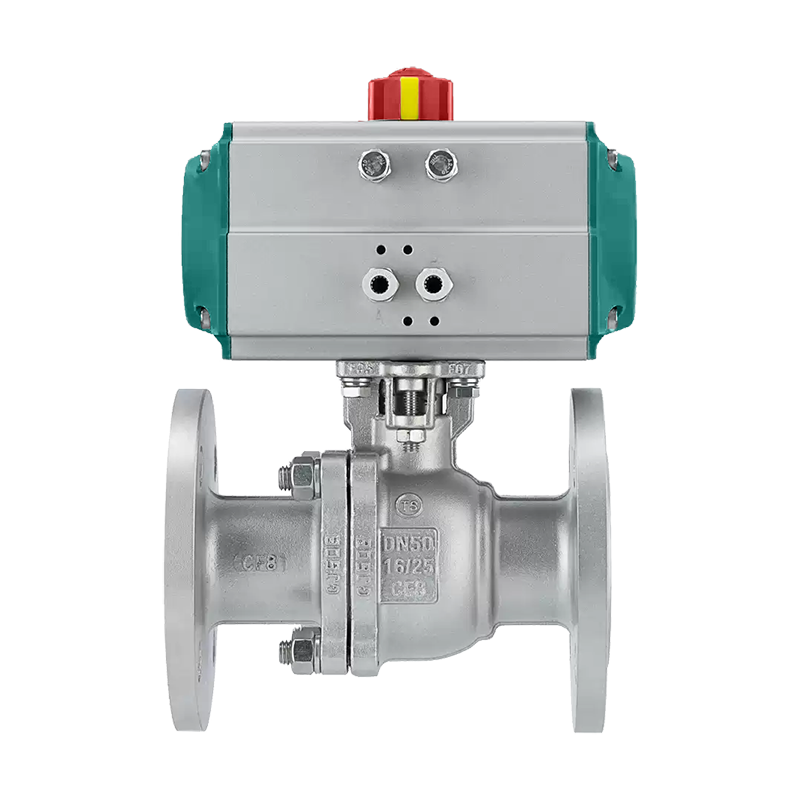

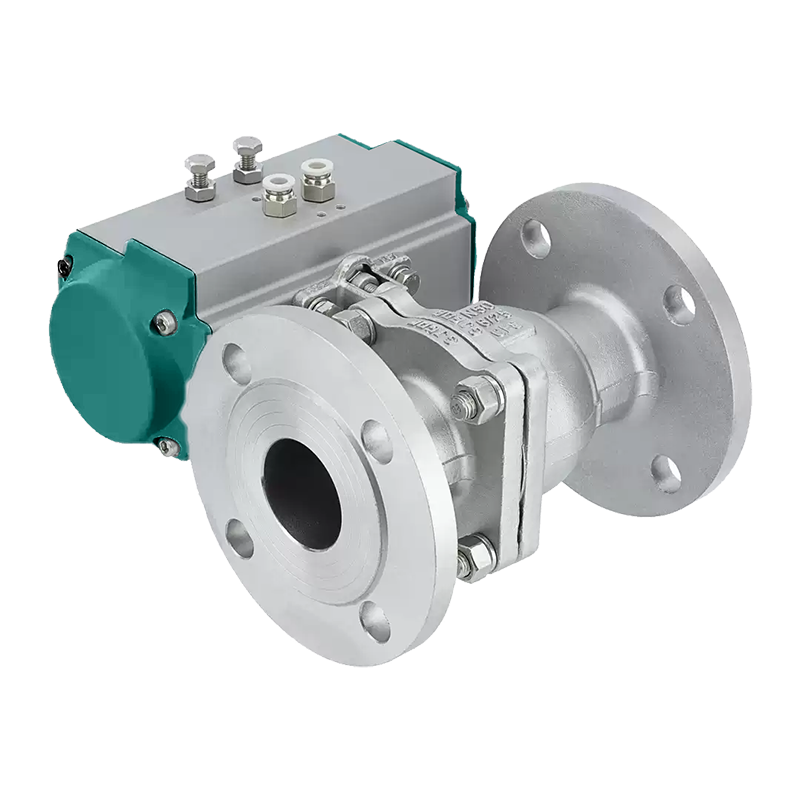

Stainless Steel Pneumatic Ball Valves

Stainless Steel Pneumatic Ball Valves: Performance, Accessories & Technical Parameters

Stainless steel pneumatic ball valves are rotary ball valves with a 90° rotation angle. They feature excellent sealing performance, large flow capacity, small flow resistance coefficient, simple structure, convenient maintenance, and long service life. The valve body channel and the connecting pipe diameter are equal and form a straight diameter, allowing the medium to flow through almost without loss. They can be equipped with double-acting or single-acting actuators. Stainless steel pneumatic ball valves are usually used in occasions with strict sealing requirements. In addition to controlling gas, liquid, and steam media, they are also suitable for controlling sewage and media containing fibrous impurities. They are widely used in petroleum, chemical, metallurgical, light industry, papermaking, power station, refrigeration and other industrial fields. As an important type of valve, stainless steel pneumatic ball valves are widely applied in petrochemical, long-distance pipeline and other fields. The closing part of the ball valve is a perforated ball (or partial ball), which rotates with the valve stem to realize the opening or closing of the valve.

Performance Advantages of Stainless Steel Pneumatic Ball Valves

Stainless steel ball valves adopt investment casting with silica sol and are connected with pneumatic actuators. They can not only be used for on-off cut-off but also for flow regulation.

Diversified options: By selecting different valve body and valve seat materials, they can be applied to media under different working conditions.

Wide application range: They can be used in normal temperature and pressure occasions, as well as widely used in high temperature, high pressure and low temperature working conditions.

Stainless steel pneumatic ball valves use gas as the power source, with a pressure generally around 0.4-0.7MPa, which is relatively safe. If air leakage occurs, the gas can be directly discharged without polluting the environment, and at the same time, it has high safety.

Accessory Options for Stainless Steel Pneumatic Ball Valves

Position Indicator: Also called limit switch, it remotely feeds back switch signals (explosion-proof available).

Solenoid Valve: 2-position 5-way for double-acting, 2-position 3-way for single-acting (explosion-proof available).

Triple Unit: Can stabilize air source pressure, filter, and add lubricating oil to the cylinder.

Cut-off Type Accessories: Single solenoid valve, double solenoid valve, limit switch position indicator.

Regulating Type Accessories: Electric positioner, pneumatic positioner, electric-pneumatic converter.

Air Source Treatment Accessories: Air filter pressure reducing valve, air source treatment triple unit.

Manual Mechanism: Handwheel rotating mechanism for manual valve opening and closing.

Technical Parameters

Caliber Range: DN15~DN250: (1/2"~10")

Pressure Range: PN1.6~6.4MPa: (150~300LB)

Temperature Range: -40℃~+425℃ (custom high temperature available)

Optional Materials: Carbon Steel, Stainless Steel, Chromium-Molybdenum Steel, Alloy Steel

Sealing Materials: PTFE, PPL, PEEK, Metal

Connection Method: Flange Type (GB, ANSI, JIS, DIN)

Drive Method: Pneumatic Actuator, Electric Actuator

Control Mode: On-Off Type, Regulating Type, Cut-Off Type

Actuator Parameters of Stainless Steel Pneumatic Ball Valves

Actuator Model: GT, AT, AR, AW series single/double-acting pneumatic actuators

Air Supply Pressure: 0.4~0.7MPa

Air Source Interface: G1/4", G1/8", G3/8", G1/2"

Ambient Temperature: -30~+70℃

Action Forms

Single-Acting Actuator: Air-Closed Type (B) -- Valve position is Open (FO) when air is lost; Air-Open Type (K) -- Valve position is Closed (FC) when air is lost.

Double-Acting Actuator: Air-Closed Type (B) -- Valve position is Held (FL) when air is lost; Air-Open Type (K) -- Valve position is Held (FL) when air is lost.