How to Correctly Use Stainless Steel Sanitary Diaphragm Valves?

How to Correctly Use Stainless Steel Sanitary Diaphragm Valves?

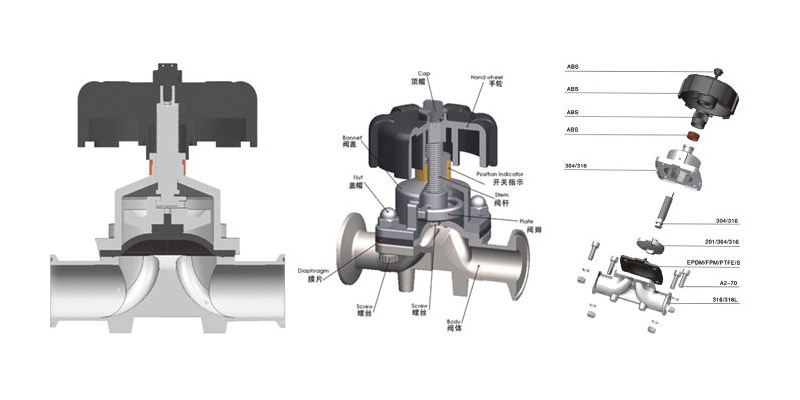

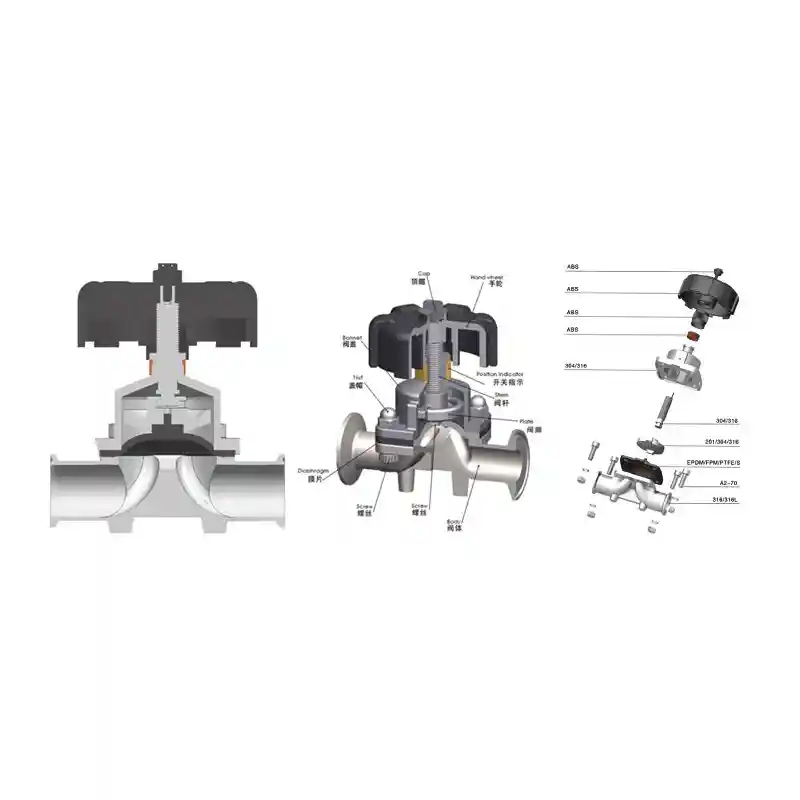

Stainless Steel Sanitary Diaphragm Valves are mainly composed of valve body, diaphragm, valve stem, valve seat, and actuating device. Among them, the diaphragm, as the core component, is usually made of soft materials such as rubber or fluoroplastic. When the actuator (e.g., pneumatic or electric actuator) pushes the valve stem downward, it further drives the diaphragm to press tightly against the valve seat, thereby blocking the fluid channel and realizing the closing of the valve; on the contrary, if the actuator lifts the valve stem, the diaphragm returns to its free state, allowing the fluid to pass through the valve smoothly. This design ensures that the medium only contacts the diaphragm and is isolated from other metal components. The elastic diaphragm separates the medium from other parts of the valve to form an effective sealing barrier. This not only prevents leakage but also avoids corrosion and contamination of the valve interior by the medium, making it particularly suitable for working environments with high purity requirements.

Precautions for Using Stainless Steel Sanitary Diaphragm Valves

Regular Cleaning

Cleaning Method: Use special cleaning agents or warm water with neutral detergent for cleaning. Avoid using acidic or alkaline solutions to prevent damage to the stainless steel surface.

Cleaning Frequency: Formulate a reasonable cleaning plan according to actual usage conditions; regular cleaning is generally recommended to maintain the cleanliness of the valve interior.

Pipeline Cleaning

Cleaning Scope: Not only focus on the valve itself but also regularly inspect and clean impurities and blockages in the connecting pipelines and interfaces.

Function: Ensure unobstructed fluid flow and avoid affecting production efficiency and product quality due to pipeline blockages.

Timely Replacement of Sealing Elements

Inspection Cycle: Regularly check the condition of the internal sealing elements of the valve. If the sealing elements are aging or worn, they should be replaced in a timely manner.

Importance: Aging or worn sealing elements can cause leakage problems, affecting the sealing performance and normal use of the valve. Therefore, timely replacement of sealing elements is crucial to ensuring the stability of the valve.

Regular Cleaning

Cleaning Method: Use special cleaning agents or warm water with neutral detergent for cleaning. Avoid using acidic or alkaline corrosive solutions to prevent damage to the stainless steel surface.

Cleaning Frequency: Formulate a reasonable cleaning plan according to actual usage conditions; regular cleaning is generally recommended to maintain the cleanliness of the valve interior.

Maintenance Records

Record Content: Establish a complete maintenance record file, detailing each cleaning, sealing element replacement, inspection and repair, including information such as time, location, operator, and specific matters.

Significance: Facilitate tracking the valve's usage status and maintenance history, providing a basis for subsequent maintenance and management.

Correct Operation

Follow Procedures: When using the valve, strictly follow the operating procedures to avoid valve damage or safety accidents caused by incorrect operation.

Moderate Force: When operating the valve manually, pay attention to controlling the force; do not use excessive force to avoid damaging the valve's operating mechanism or other components.

Correct Operation

Follow Procedures: Strictly follow the operating procedures when using the valve to avoid valve damage or safety accidents caused by improper operation.

Moderate Force: When operating the valve manually, pay attention to controlling the force; do not use excessive force to avoid damaging the valve's operating mechanism or other components.

Timely Replacement of Sealing Elements

Inspection Cycle: Regularly check the condition of the internal sealing elements of the valve. If the sealing elements are outdated or worn, they should be replaced in a timely manner.

Importance: Outdated or worn sealing elements will cause leakage problems, affecting the sealing performance and normal use of the valve. Therefore, timely replacement of sealing elements is crucial to ensuring the stability of the valve.

Environmental Adaptability Considerations

Temperature and Humidity: Pay attention to changes in temperature and humidity of the operating environment; avoid the valve being in special environments for a long time to prevent affecting its performance and service life.

Corrosive Substances: If there are corrosive gases or other harmful substances in the surrounding area, take corresponding protective measures such as installing protective covers to prevent the valve from corrosion.

Consideration of Environmental Adaptability

Temperature and Humidity: Pay attention to changes in temperature and humidity of the operating environment; avoid the valve being in special environments for a long time to prevent affecting its performance and service life.

Corrosive Substances: If there are corrosive gases or other harmful substances in the surrounding area, take corresponding protective measures such as installing protective covers to prevent the valve from being eroded.

Maintenance Records

Record Content: Establish a complete maintenance record file, detailing each cleaning, sealing element replacement, inspection and repair, including information such as time, location, operator, and specific matters.

Significance: Facilitate tracking the usage status and maintenance history of the valve, providing a basis for subsequent maintenance and management.

Pipeline Cleaning

Cleaning Scope: Not only focus on the valve itself but also regularly inspect and clean impurities and blockages in the connecting pipelines and interfaces.

Function: Ensure unobstructed fluid flow and avoid affecting production efficiency and product quality due to pipeline blockage.

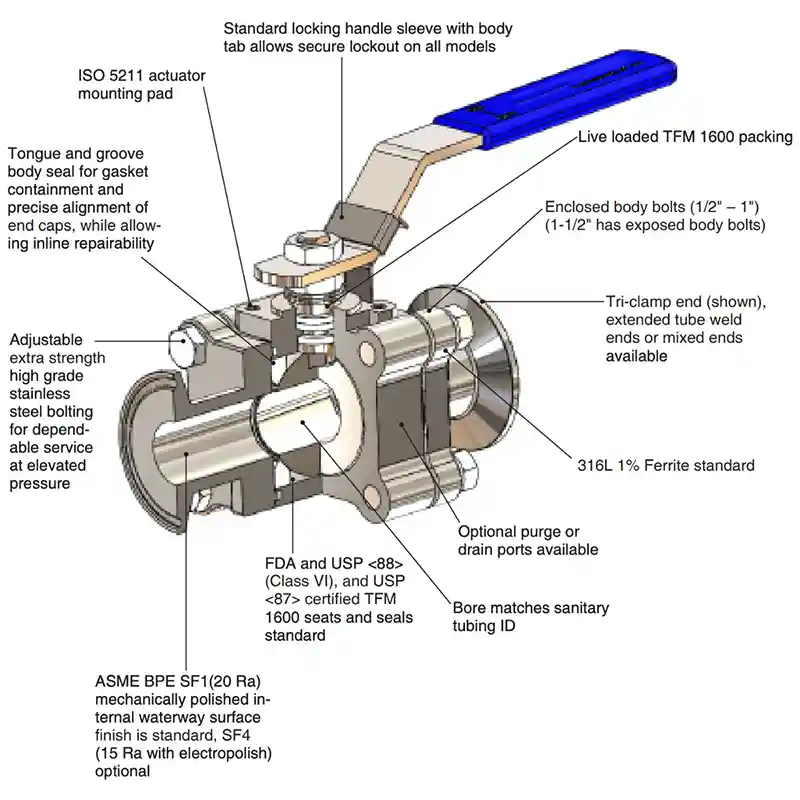

How to operate a sanitary ball valve?

How to operate a sanitary ball valve?

How to Correctly Use Stainless Steel Sanitary Diaphragm Valves?

How to Correctly Use Stainless Steel Sanitary Diaphragm Valves?

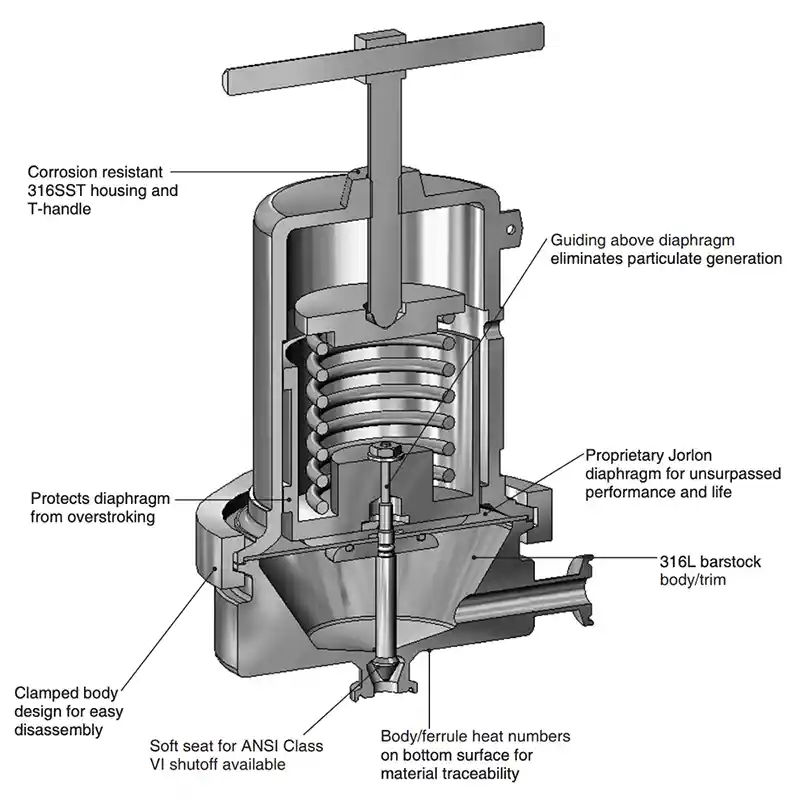

What is a Sanitary Pressure Regulator?

What is a Sanitary Pressure Regulator?

What Are Sanitary Valves?

What Are Sanitary Valves?