What Are Sanitary Valves?

Sanitary Valves: Overview, Types, Requirements & Differences

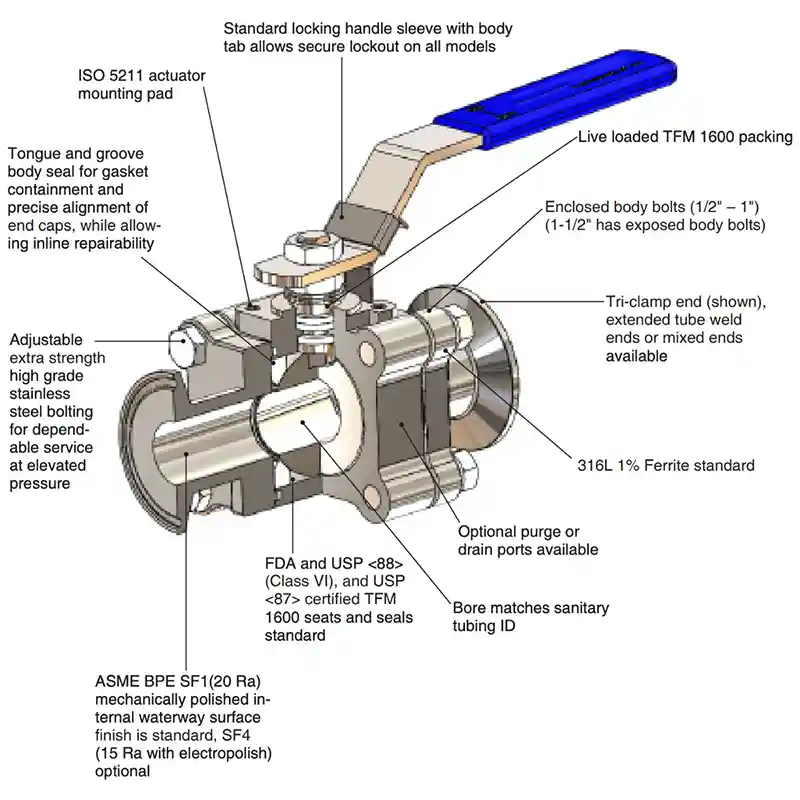

As the name suggests, sanitary valves refer to valves that meet hygiene standards (medical standards or food standards). The valve body must meet stainless steel hygiene standards, and all parts in contact with the medium must be mirror polished. Both the polishing and cleanliness must comply with hygiene standards and meet the hygiene requirements of valve components. They are mainly used in food processing, pharmaceuticals, clean areas of hospitals, and occasions with high hygiene level requirements and no physical or chemical hazards.

Types of Sanitary Valves

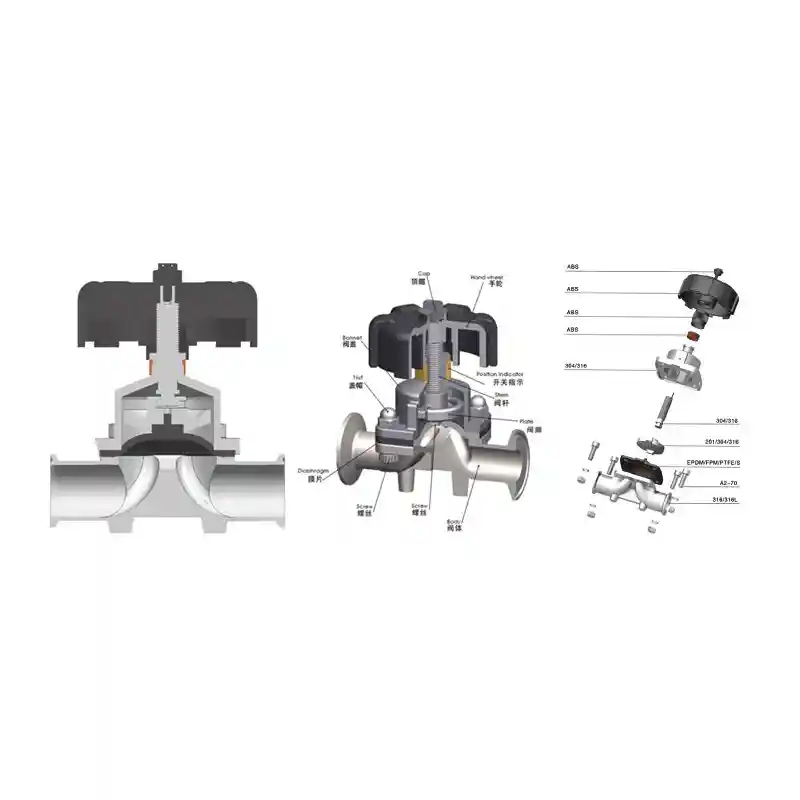

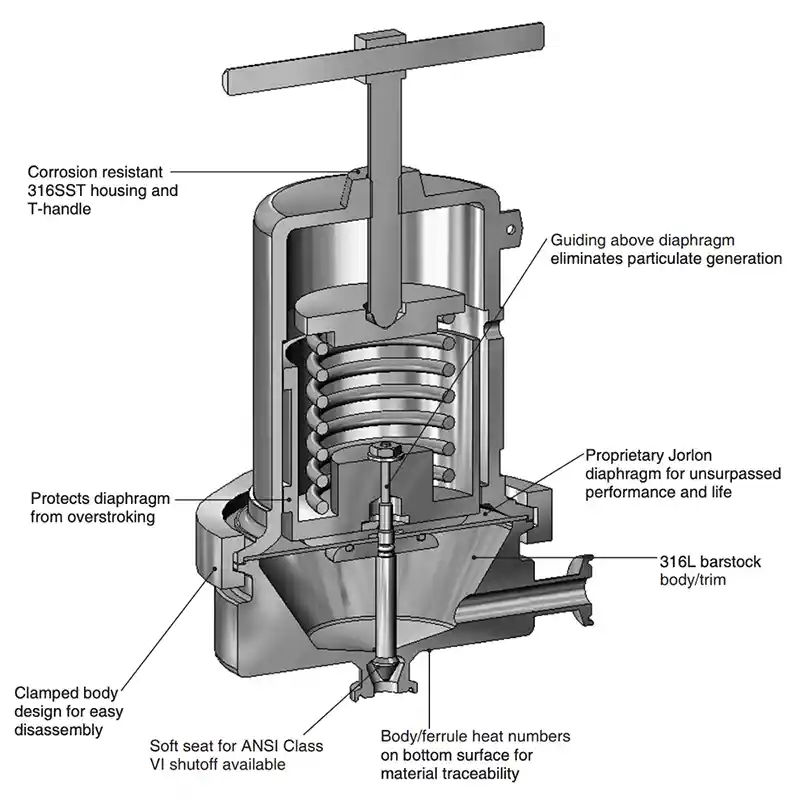

Sanitary valves have requirements for their valve body materials and sealing materials. The materials are basically stainless steel, and the valve seat sealing surface must use non-toxic materials. For example, hard seals are made of stainless steel, and soft seals are made of rubber (EPDM is usually used within 140℃; fluororubber is toxic and cannot be used). Common types of sanitary valves include: Sanitary Butterfly Valve, Sanitary Ball Valve, Sanitary Check Valve, Sanitary Solenoid Valve, and Sanitary Diaphragm Valve.

Mechanical Seal Requirements for Sanitary Valves

Comply with GMP requirements;

Surface finish above 1.6;

The contact surface can realize Clean-in-Place (CIP) and Sterilize-in-Place (SIP);

Smooth transition without material accumulation;

There is a structure outside the sealing surface to prevent material cross-contamination.

Differences Between Sanitary Valves and Ordinary Valves

Strictly speaking, sanitary valves have high-specification manufacturing standards. They are mainly developed for some biological fermentation enterprises and have particularly high requirements for the finish of the valve flow channel. Most parts of sanitary valves in contact with the medium are made of stainless steel, usually 304SS or 316 stainless steel, which are non-toxic, harmless, and have a clean and smooth surface that will not corrode or peel off. After production and processing, they undergo special treatment and are incomparable to industrial valves in many aspects, such as cleanliness and simple installation methods. They are special valves for food, pharmaceutical and other industries.

Ordinary industrial valves are generally modeled according to the needs of operating conditions. Many are used in high-temperature and high-pressure working environments and are widely applied in machinery, metallurgy, petrochemical, chemical, urban construction and other industries, with the characteristics of long service life and flexible operation methods. Although the appearance and interior are not as smooth and beautiful as sanitary valves, they are irreplaceable by sanitary valves in many occasions.

How to operate a sanitary ball valve?

How to operate a sanitary ball valve?

How to Correctly Use Stainless Steel Sanitary Diaphragm Valves?

How to Correctly Use Stainless Steel Sanitary Diaphragm Valves?

What is a Sanitary Pressure Regulator?

What is a Sanitary Pressure Regulator?

What Are Sanitary Valves?

What Are Sanitary Valves?