What is a Sanitary Pressure Regulator?

Sanitary Pressure Regulator: Introduction, Working Principle, Characteristics & Technical Parameters

Introduction to Sanitary Pressure Regulator

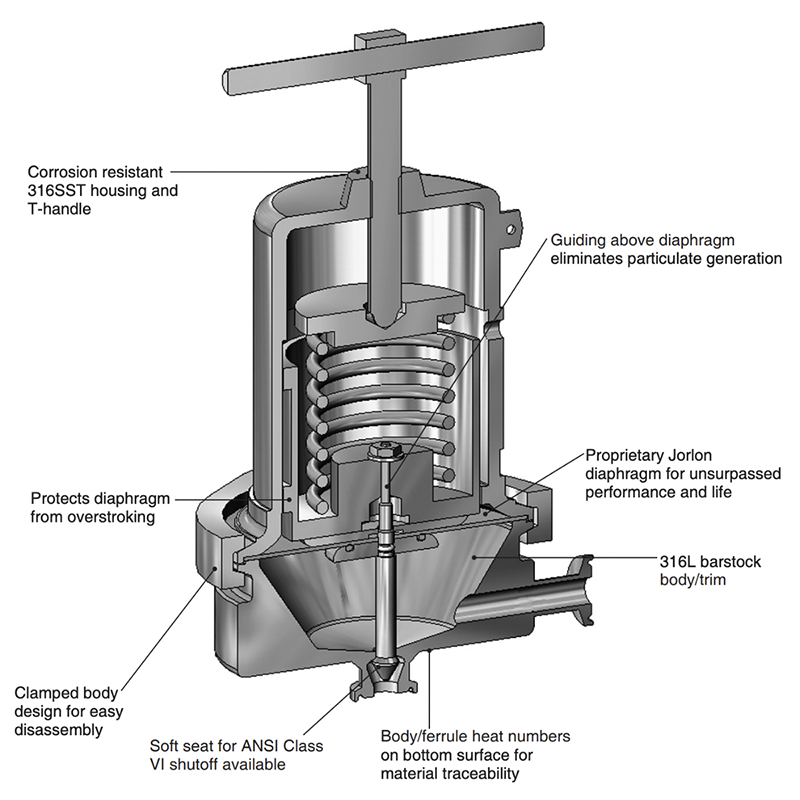

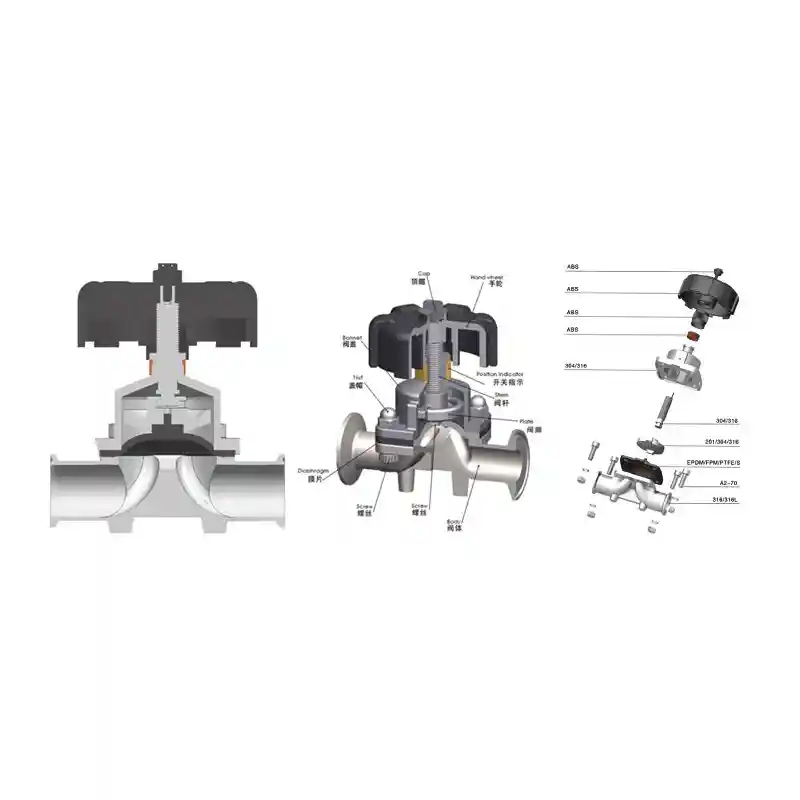

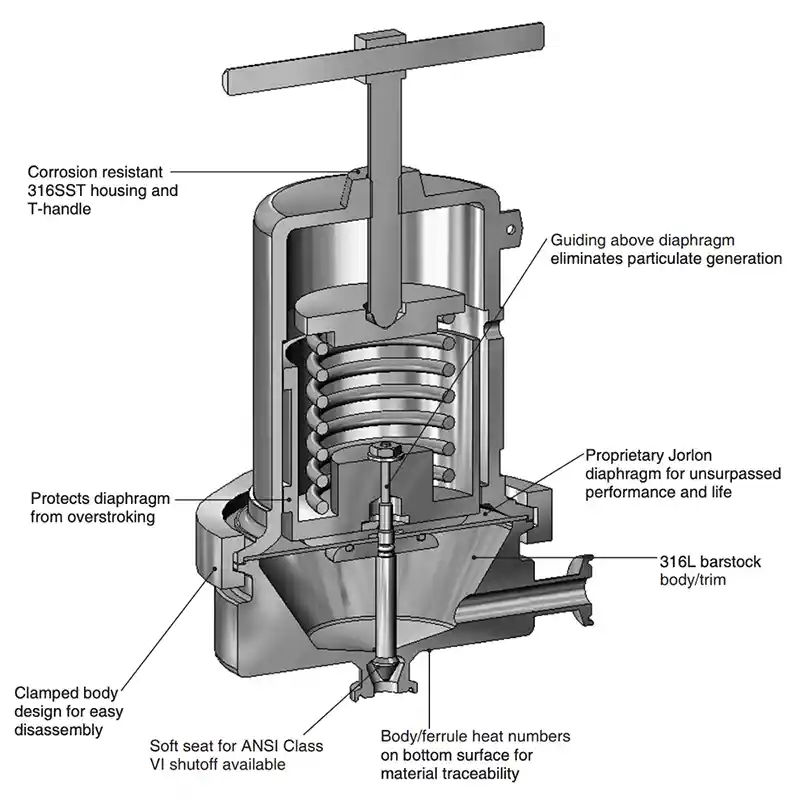

A Sanitary Pressure Regulator, also known as a Stainless Steel Food-Grade Pressure Regulating Valve or Sanitary Cartridge Regulating Valve, is mainly composed of adjusting spring, diaphragm, piston, valve seat, valve disc and other components. It adjusts the pressure to set the outlet pressure by adjusting the pressure relief valve spring, uses the diaphragm to directly sense the downstream pressure to drive the valve disc, and senses the change of outlet pressure through the diaphragm. It drives the piston to adjust the flow area of the throttling part of the main valve through the opening and closing of the pilot valve, so as to realize the pressure reduction and stabilization function. The action form of the Sanitary Pressure Regulator is to adjust the opening degree of the opening and closing part in the valve body to regulate the flow rate of the medium, reduce the pressure of the medium, and at the same time adjust the opening degree of the opening and closing part with the help of the action of the pressure after the valve, so that the pressure after the valve is kept within a certain range. A notable feature of the Sanitary Pressure Regulator is that it can maintain the outlet pressure and temperature within a certain range when the inlet pressure changes continuously.

A Sanitary Pressure Regulator is a valve that reduces the inlet pressure to a required outlet pressure through adjustment and automatically maintains the outlet pressure stable by relying on the energy of the medium itself. Specifically, it changes the throttling area to alter the flow rate and fluid kinetic energy, resulting in different pressure losses, thereby achieving the purpose of pressure reduction. Then, relying on the adjustment of the control and regulation system, the fluctuation of the pressure after the valve is balanced with the spring force, so that the pressure after the valve is kept constant within a certain error range.

Working Principle of Sanitary Pressure Regulator

A Sanitary Pressure Regulator is a valve that reduces the inlet pressure to a required outlet pressure through adjustment and automatically maintains the outlet pressure stable by relying on the energy of the medium itself. Its working principle is to change the throttling area to alter the flow rate and fluid kinetic energy, resulting in different pressure losses, thereby achieving the purpose of pressure reduction. Then, relying on the adjustment of the control and regulation system, the fluctuation of the pressure after the valve is balanced with the spring force, so that the pressure after the valve is kept constant within a certain error range. Hence, it is also known as Sanitary Pressure Regulating Valve or Sanitary Control Valve.

Characteristics of Sanitary Pressure Regulator (Food-Grade Pressure Regulating Valve)

Balanced pressure reducing structure improves the stability of output pressure.

Locknut can control the setting of the adjusting screw.

Temperature range: -15-165°C; Weight: 7KG; Flow rate: 15m³/h

Components are cleaned in accordance with HG20202 requirements; the internal and external surfaces of the valve body are mirror polished, meeting GMP cleanliness requirements and suitable for use in pure oxygen and high-cleanliness environments.

100% factory tested.

Technical Parameters of Sanitary Pressure Regulator (Food-Grade Pressure Regulating Valve)

Valve Specification: DN15~DN50mm (1/2"~2")

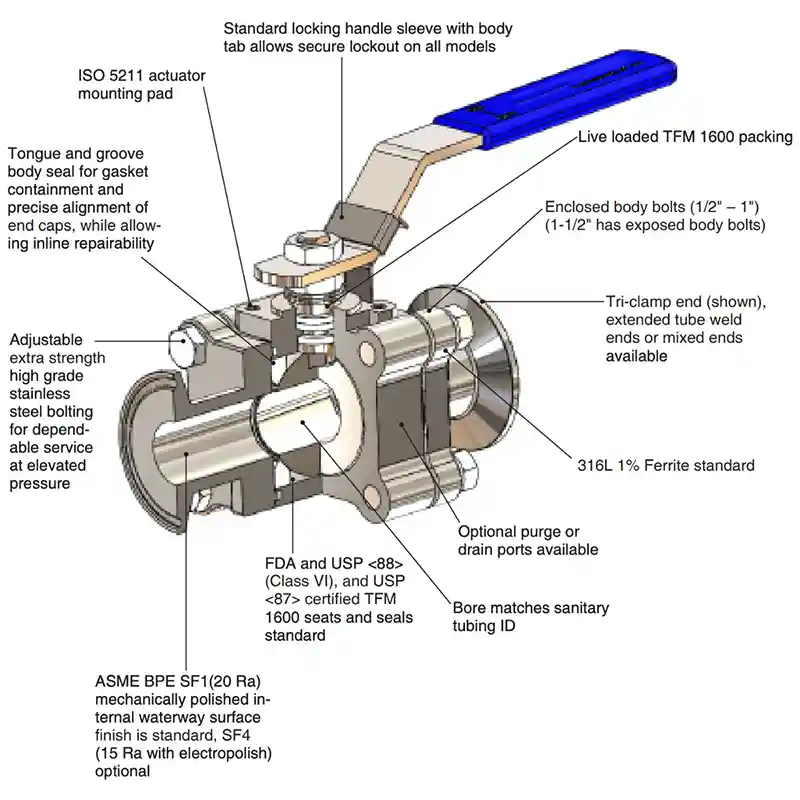

Connection Method: Clamp (Quick-Install), Union Threaded, Butt Welded, Flange

Valve Body Material: 304, 316, 304L, 316L, etc.

Applicable Medium: Food, pharmaceuticals, dairy products, liquids, gases, compressed air, water, etc.

Valve Operating Parameters: Inlet pressure 1.0MPA (10kg); Outlet pressure adjustment range: 0.08~0.8MPA (0.8~8kg)

Pressure Adjustment Range of Sanitary Pressure Regulator

Adjustment Range: 1kgf/cm²-6kgf/cm², 4kgf/cm²-10kgf/cm², 8kgf/cm²-13kgf/cm²; special working fluids and adjustment ranges can be customized.

Pressure required for the valve to go from fully closed to fully open: Outlet pressure 1.5kgf/cm².

Test Pressure: 35kgf/cm².

Specification: DN15-DN80, 1/2'-4'

Standard: ISO, IDF, DIN, 3A, SMS

Applicable temperature: -20°~180°

Inlet maximum pressure: 2.5MPA

Outlet adjustable pressure: 0~1.0MPA

Valve body material: SUS304, SUS316L

Connection method: Threaded, Clamp (Quick-Install), Welded, Flange

Sealing ring material: EPDM, FPM, SI

Applicable medium: Steam, nitrogen, carbon dioxide, water, etc.

Application scope: Dairy products, beer, food, beverages

How to operate a sanitary ball valve?

How to operate a sanitary ball valve?

How to Correctly Use Stainless Steel Sanitary Diaphragm Valves?

How to Correctly Use Stainless Steel Sanitary Diaphragm Valves?

What is a Sanitary Pressure Regulator?

What is a Sanitary Pressure Regulator?

What Are Sanitary Valves?

What Are Sanitary Valves?