How to operate a sanitary ball valve?

Stainless Steel Sanitary Ball Valve: Specifications, Applications & Disassembly Guide

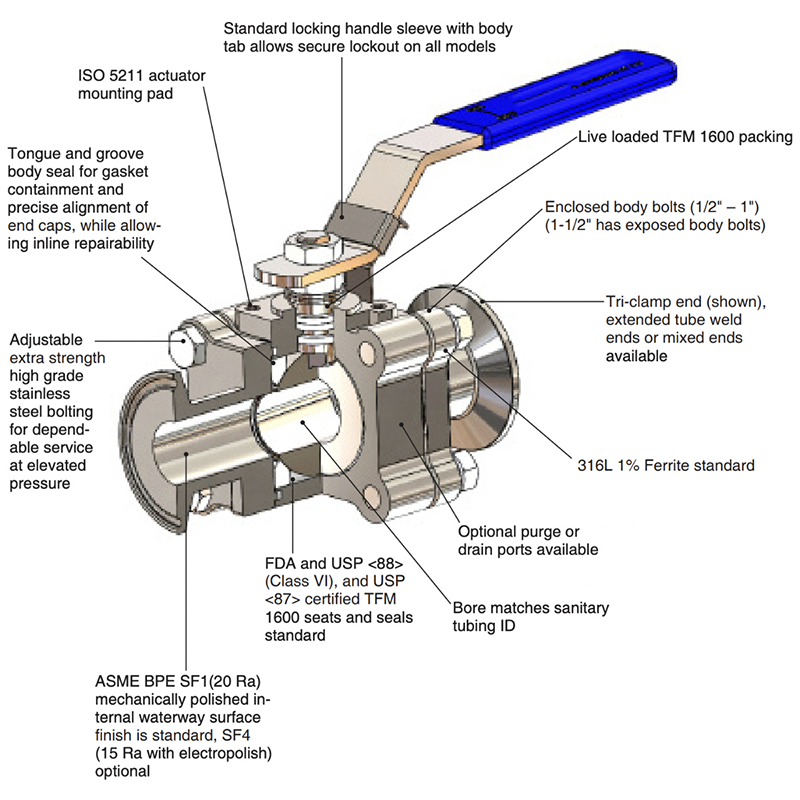

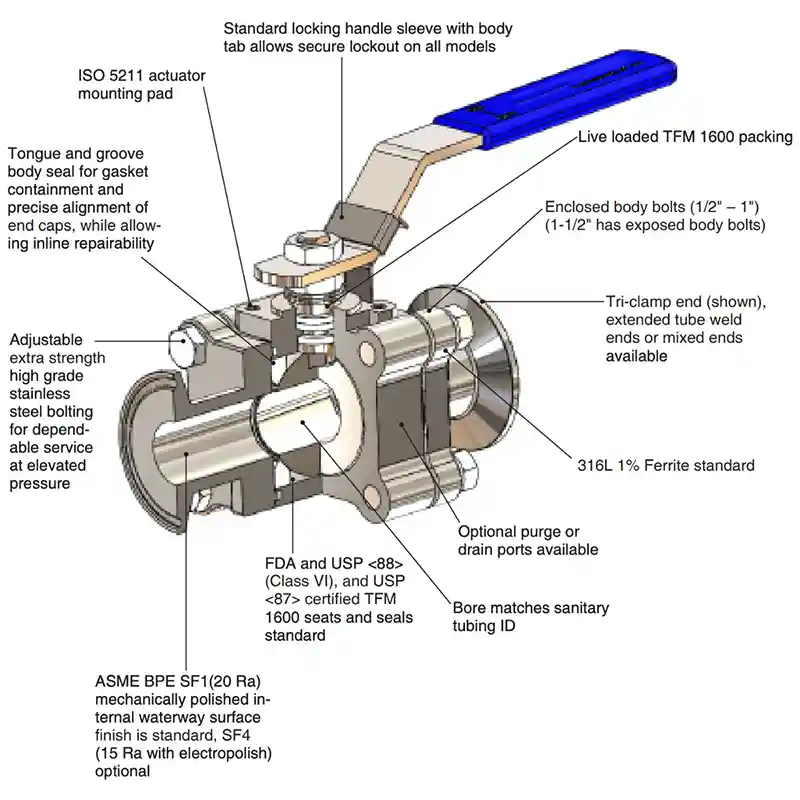

For Stainless Steel Sanitary Ball Valves, the driving methods can be selected from manual, worm gear, pneumatic, and electric; the connection methods can be flange, wafer, clamp (quick-install), and cartridge; the structural form can be straight-through; the sealing structure can be soft seal or hard seal. The pressure range is PN0.1-10Mpa, the nominal diameter is DN6-100mm, and the material can be stainless steel. Due to the wide application range of the valve, the same type of valve has different configurations in different occasions and working conditions.

Sanitary Ball Valves are made of SUS304 and 316L, which can meet the special requirements of various media in the food and biopharmaceutical fields. Their smooth, seamless, and self-draining process fluid channels are also very suitable for the needs of steam and Clean-in-Place (CIP). During the manufacturing and processing, quality control is strictly carried out in accordance with FDA requirements, and computer-aided 3D design is adopted, making them manufactured to meet GMP requirements.

In the process of using the Stainless Steel Sanitary Ball Valve, if it is necessary to disassemble the Sanitary Ball Valve, the following tools are required:

Locking Wrench: Including fixed hook wrench, adjustable hook wrench, and U-shaped locking wrench.

Fixed Wrench: Used to turn nuts of a specific specification. Compared with adjustable wrenches, fixed wrenches are less likely to damage nuts and bolts.

Sanitary Ball Valve Socket Wrench: Composed of box-end wrenches of different sizes, used for hard-to-reach positions.

Sanitary Ball Valve Handwheel Wrench: Can be welded with pipes and round steel, commonly used for opening and closing handwheels.

Sanitary Ball Valve Special Wrench: Including ratchet wrench and torque wrench, etc. The ratchet wrench does not need to change the angle when turning.

During the disassembly of the Sanitary Ball Valve, attention should be paid to the valve seat: do not scratch it with hard objects, otherwise the sealing will be incomplete. In addition, the ball should not be placed randomly, as it is easy to lose. It is also important to note that the entire disassembly process must be carried out under the premise of pressure relief.

How to operate a sanitary ball valve?

How to operate a sanitary ball valve?

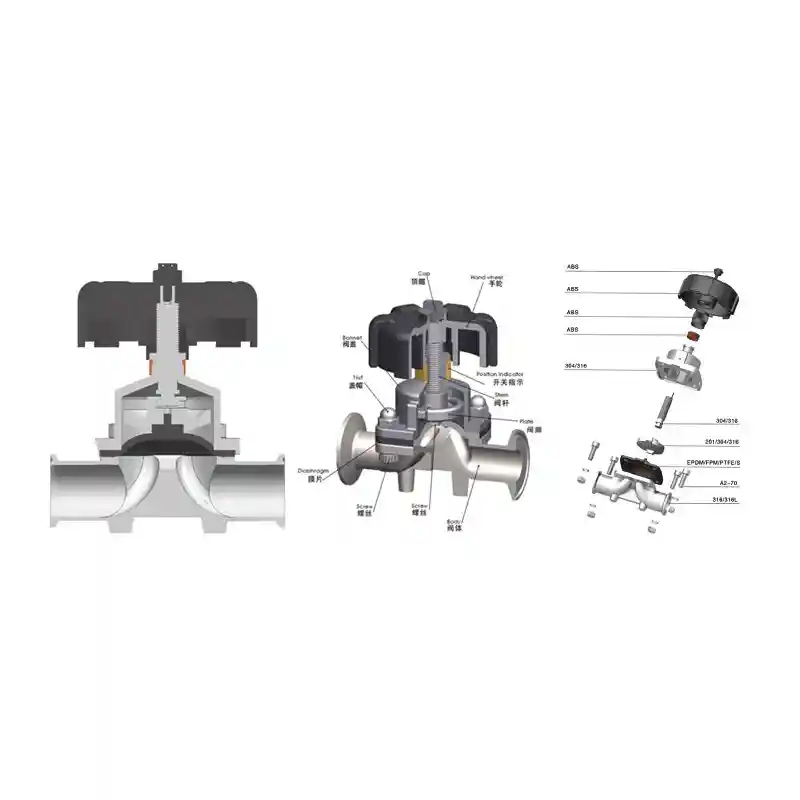

How to Correctly Use Stainless Steel Sanitary Diaphragm Valves?

How to Correctly Use Stainless Steel Sanitary Diaphragm Valves?

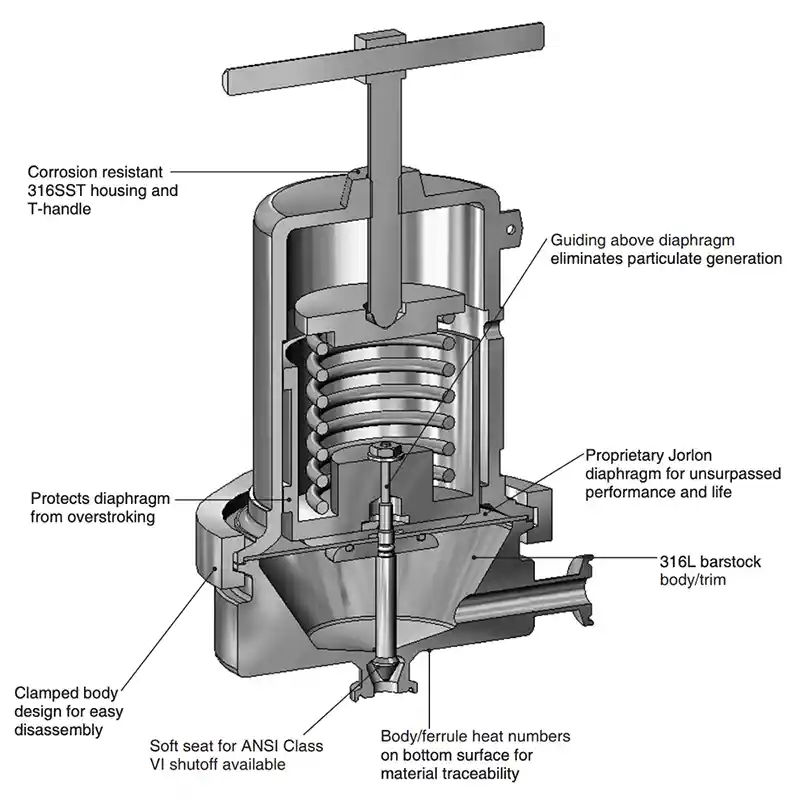

What is a Sanitary Pressure Regulator?

What is a Sanitary Pressure Regulator?

What Are Sanitary Valves?

What Are Sanitary Valves?