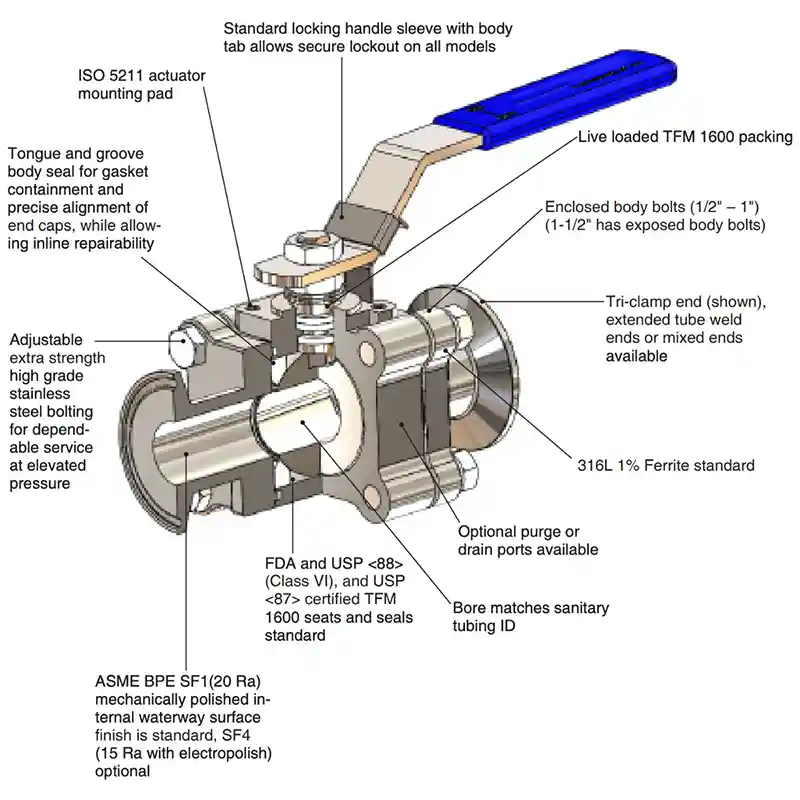

Structure of Sanitary Ball Valves with Clamp Ends

Structure of Sanitary Ball Valves with Clamp Ends

For Stainless Steel Sanitary Ball Valves, the driving methods can be selected from manual, worm gear, pneumatic, and electric; the connection methods can be flange, wafer, clamp (quick-install), and cartridge; the structural form can be straight-through; the sealing structure can be soft seal or hard seal. The pressure range is PN0.1-10Mpa, the nominal diameter is DN6-100mm, and the material can be stainless steel. Due to the wide application range of the valve, the same type of valve has different configurations in different occasions and working conditions.

Sanitary Ball Valves are made of SUS304 and 316L, which can meet the special requirements of various media in the food and biopharmaceutical fields. Their smooth, seamless, and self-draining process fluid channels are also very suitable for the needs of steam and Clean-in-Place (CIP). During the manufacturing and processing, quality control is strictly carried out in accordance with FDA requirements, and computer-aided 3D design is adopted, making them manufactured to meet GMP requirements.

In the process of using the Stainless Steel Sanitary Ball Valve, if it is necessary to disassemble the Sanitary Ball Valve, the following tools are required:

Locking Wrench: Including fixed hook wrench, adjustable hook wrench, and U-shaped locking wrench.

Fixed Wrench: Used to turn nuts of a specific specification. Compared with adjustable wrenches, fixed wrenches are less likely to damage nuts and bolts.

Sanitary Ball Valve Socket Wrench: Composed of box-end wrenches of different sizes, used for hard-to-reach positions.

Sanitary Ball Valve Handwheel Wrench: Can be welded with pipes and round steel, commonly used for opening and closing handwheels.

Sanitary Ball Valve Special Wrench: Including ratchet wrench and torque wrench, etc. The ratchet wrench does not need to change the angle when turning.

During the disassembly of the Sanitary Ball Valve, attention should be paid to the valve seat: do not scratch it with hard objects, otherwise the sealing will be incomplete. In addition, the ball should not be placed randomly, as it is easy to lose. It is also important to note that the entire disassembly process must be carried out under the premise of pressure relief.

Sanitary Clamp (Quick-Install) Ball Valve

A Sanitary Clamp (Quick-Install) Ball Valve is a type of valve that combines clamp (quick-install) connection and ball valve opening/closing functions. It is widely used in fluid control scenarios requiring rapid installation, disassembly, and frequent opening/closing, and its working principle is based on the rotational movement of the ball. When the valve needs to be opened, the valve stem is rotated by operating the handle or actuating devices (such as electric or pneumatic actuators), driving the ball to rotate 90°, aligning the through hole on the ball with the channels at both ends of the valve body, allowing fluid to pass through the valve smoothly. When the valve needs to be closed, the valve stem is rotated in the reverse direction, making the ball rotate 90°, so that the through hole is perpendicular to the channels, blocking the flow of fluid and realizing the closing of the valve.

Structure of Sanitary Clamp (Quick-Install) Ball Valve

Valve Body: The valve body usually adopts an integrated design with various materials, commonly including stainless steel (such as 304, 316 stainless steel), carbon steel, plastics (such as PVC, PP, etc.). The integrated structure reduces leakage points and enhances the overall strength and sealing performance of the valve.

Ball: The ball is a key component of the Sanitary Clamp (Quick-Install) Ball Valve, generally of solid structure. Its material is compatible with the valve body to ensure good corrosion resistance and wear resistance.

Valve Seat: The valve seat surrounds the ball and plays a sealing role to prevent fluid leakage. The valve seat material is usually PTFE, nylon, rubber and other materials with good elasticity and sealing performance. Some also adopt metal hard seal structure, which is suitable for high temperature, high pressure and strong corrosive media.

Clamp (Quick-Install) Joint: This is a characteristic component of the Sanitary Clamp (Quick-Install) Ball Valve, generally composed of a clamp, a sealing ring and a joint body. The clamp can quickly connect or disassemble the valve with the pipeline, and the sealing ring ensures the sealing performance of the connection to prevent fluid leakage. The material of the clamp (quick-install) joint is usually consistent with the valve body to ensure compatibility and corrosion resistance.

Valve Stem: The valve stem connects the ball and the operating handle (or actuating device) and is used to transmit the operating force to rotate the ball to realize the opening and closing of the valve. A sealing structure is usually adopted between the valve stem and the valve body to prevent medium leakage from the valve stem.

Application Scenarios of Sanitary Clamp (Quick-Install) Ball Valve

Food and Beverage Industry: High hygiene requirements are required in the production process of food and beverage. Adopting stainless steel material and sanitary design, it can meet the hygiene standards of food production, and the feature of quick installation and disassembly facilitates the cleaning and disinfection of equipment. It is often used for fluid control in production lines of milk, beer, beverages, etc.

Pharmaceutical Industry: Pharmaceutical production requires a strict sterile environment and accurate fluid control. It has good sealing performance, which can prevent drugs from being contaminated. At the same time, its quick connection and disassembly functions facilitate the maintenance and replacement of production equipment, and it is suitable for various fluid delivery systems in the pharmaceutical production process.

Chemical Industry: Chemical production often involves various corrosive media and high-temperature and high-pressure working conditions. Appropriate materials and sealing structures can be selected according to different chemical media to ensure the reliable operation of the valve in harsh chemical environments. It is widely used in chemical raw material transportation, reactor inlet and outlet control and other links.

Water Treatment Industry: In water treatment systems, water needs to be filtered, dosed, disinfected and other treatment processes. It can be quickly installed and disassembled, facilitating the maintenance and overhaul of equipment. At the same time, its good sealing performance can prevent water leakage and ensure the normal operation of the water treatment system.

Structure of Sanitary Ball Valves with Clamp Ends

Structure of Sanitary Ball Valves with Clamp Ends

How to operate a sanitary ball valve?

How to operate a sanitary ball valve?

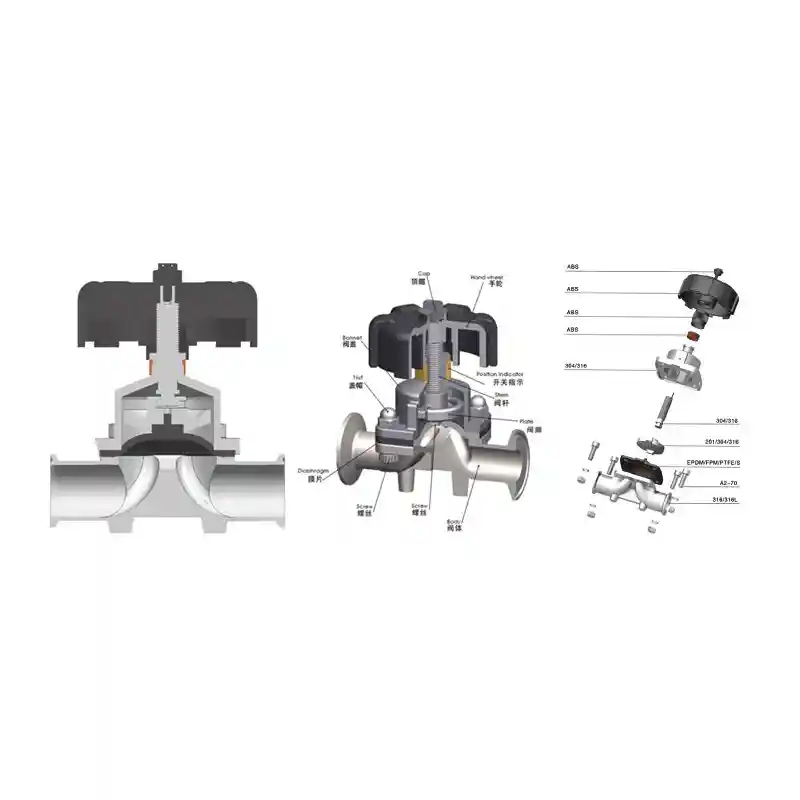

How to Correctly Use Stainless Steel Sanitary Diaphragm Valves?

How to Correctly Use Stainless Steel Sanitary Diaphragm Valves?

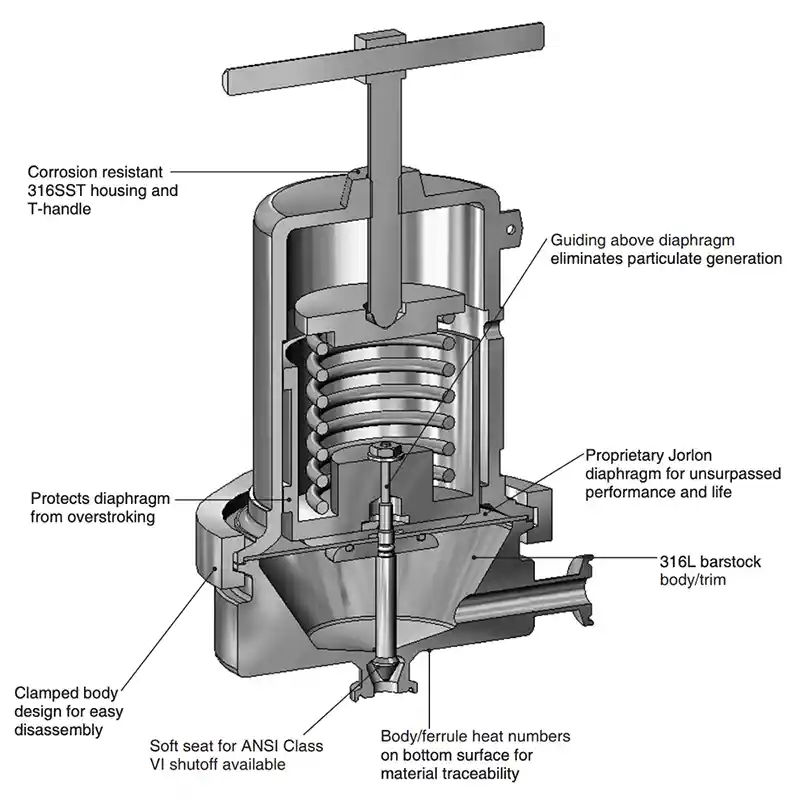

What is a Sanitary Pressure Regulator?

What is a Sanitary Pressure Regulator?