What are Sanitary Pneumatic Diaphragm Valves?

Sanitary Pneumatic Diaphragm Valve: Overview, Principle, Structure & Advantages

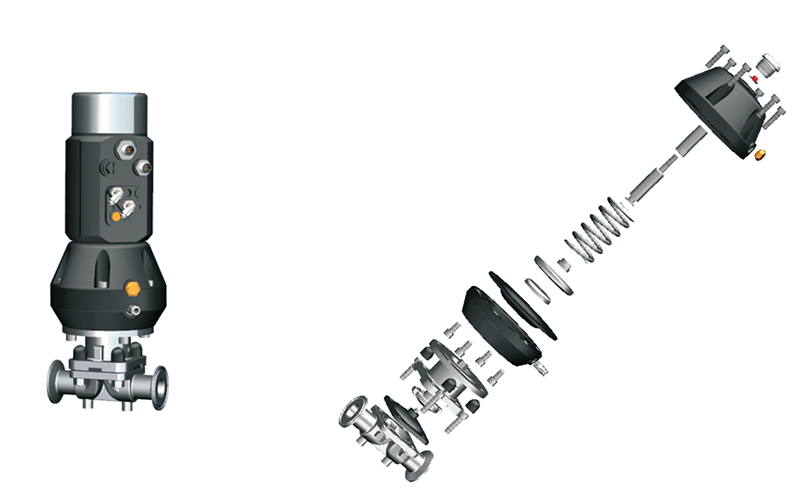

A Sanitary Pneumatic Diaphragm Valve is a type of valve that uses compressed air as the power source to realize fluid on-off or regulation through the flexible deformation of the diaphragm. It is widely applied in chemical, pharmaceutical, food, water treatment and other occasions requiring high cleanliness or strong corrosive media. Its core principle is based on the isolation function of the diaphragm and the drive of the pneumatic actuator, featuring simple structure, reliable sealing, corrosion resistance and other advantages.

Compressed air enters the cylinder through the solenoid valve, pushing the piston to move downward, driving the diaphragm to bend downward, so that the valve body channel is opened and fluid passes through; when the solenoid valve switches, the compressed air in the cylinder is discharged, the piston resets under the action of spring force or medium pressure, the diaphragm returns to its original state, the valve body channel is closed, and the fluid is cut off; by adjusting the pressure or flow rate of compressed air, the deformation degree of the diaphragm can be controlled to realize the adjustment of valve opening (needing to be matched with a positioner); the diaphragm fits closely with the sealing surface of the valve body to form a leak-free sealing structure, which is suitable for high-viscosity, particle-containing or strong corrosive media; it does not require the packing seal of traditional valves, avoiding medium leakage and packing wear problems.

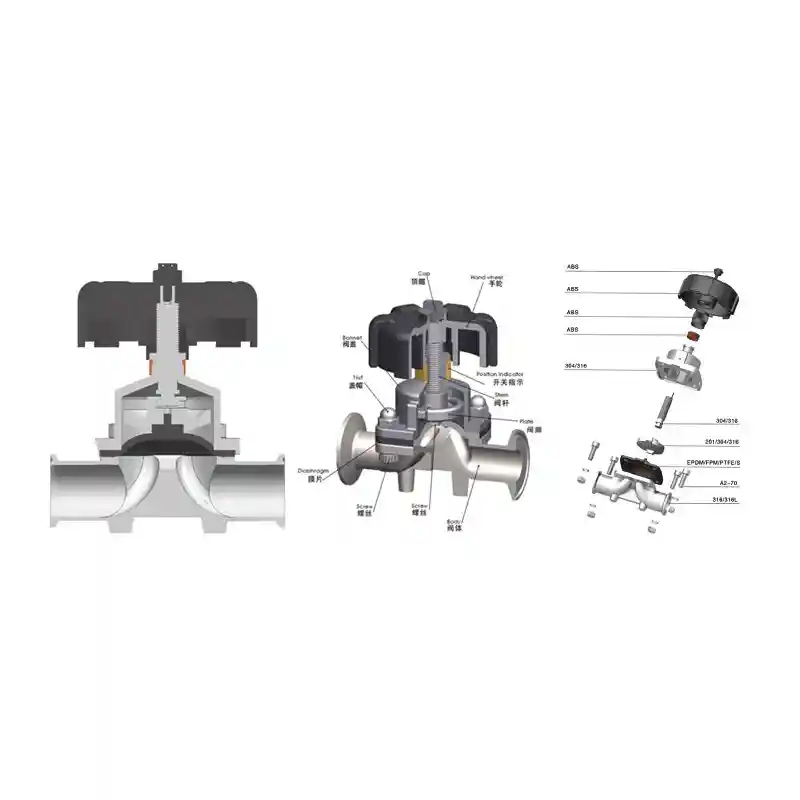

Structural Composition of Sanitary Pneumatic Diaphragm Valve

Valve Body: Usually of straight-through or angle structure, with materials including stainless steel, plastic (such as PVC, PP), cast iron, etc., used to contain fluid.

Diaphragm: Core component, made of rubber (such as EPDM, PTFE), plastic or composite materials, used to isolate the valve body from the actuator and prevent medium leakage.

Pneumatic Actuator: Composed of cylinder, piston, spring, etc., which pushes the piston to move through compressed air and drives the diaphragm to deform.

Control Components: Including solenoid valve, limit switch, positioner, etc., used to control the on-off of compressed air and the valve opening.

Advantages of Sanitary Pneumatic Diaphragm Valve

Zero Leakage: The diaphragm isolates the valve body from the actuator, so that the medium cannot enter the pneumatic part, ensuring no external leakage.

Resistance to Particle Media: The diaphragm can block solid particles in the fluid, avoiding valve jamming or sealing surface wear.

Diverse Material Selection: The valve body and diaphragm can be made of corrosion-resistant materials (such as stainless steel, PTFE diaphragm) according to the characteristics of the medium, suitable for strong corrosive media such as acids, alkalis and organic solvents.

No Metal Contact: There are no metal components in the fluid channel, avoiding chemical reactions between the medium and metal.

No Dead Angle Design: The interior of the valve body is smooth, with no liquid accumulation area, easy to clean and disinfect, meeting GMP, FDA and other hygiene standards.

Suitable for Food and Pharmaceutical Industries: Widely used in food and beverage, biopharmaceutical and other industries with high hygiene requirements.

What are Sanitary Pneumatic Diaphragm Valves?

What are Sanitary Pneumatic Diaphragm Valves?

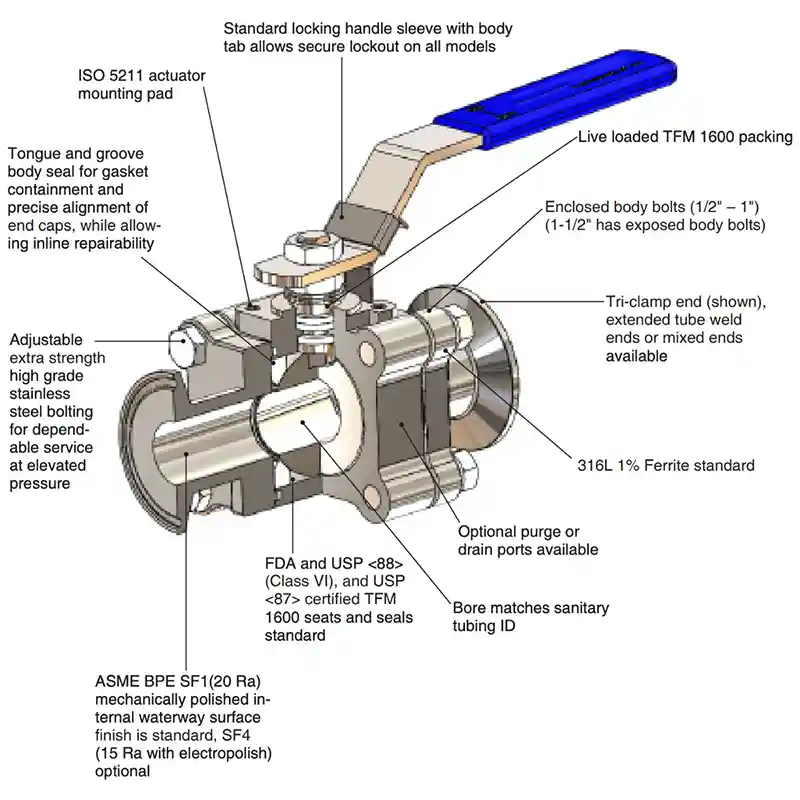

Structure of Sanitary Ball Valves with Clamp Ends

Structure of Sanitary Ball Valves with Clamp Ends

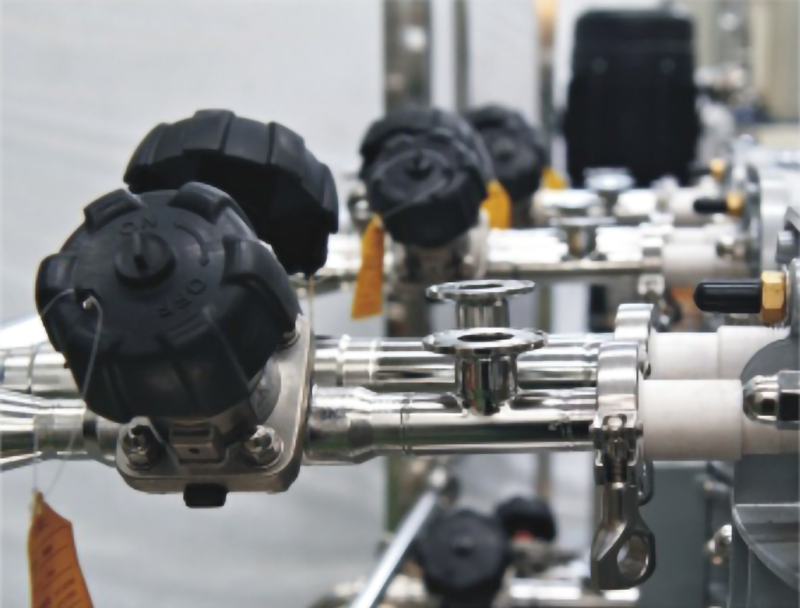

How to operate a sanitary ball valve?

How to operate a sanitary ball valve?

How to Correctly Use Stainless Steel Sanitary Diaphragm Valves?

How to Correctly Use Stainless Steel Sanitary Diaphragm Valves?