What are Stainless Steel Sanitary Butterfly Valves?

Stainless Steel Sanitary Butterfly Valve: Design, Performance & Application

In terms of appearance and structural design, the stainless steel sanitary butterfly valve has a concise and smooth overall shape with no redundant protrusions or gaps. This design is not only aesthetically pleasing but also, more importantly, meets hygiene standards, avoiding the residue of dirt and bacteria. The valve body is usually made of high-quality stainless steel, which has the characteristics of corrosion resistance, high strength, and easy cleaning. It can adapt to various complex working conditions, withstand frequent cleaning and disinfection processes, and will not rust or corrode due to long-term use, thus ensuring the reliability and stability of the valve during long-term operation.

The core component of the stainless steel sanitary butterfly valve is the butterfly plate, which realizes the opening and closing of the valve through rotation. The butterfly plate is closely connected to the valve stem, and the valve stem is connected to the operating mechanism. When the operating mechanism (such as a handle, pneumatic actuator, or electric actuator) drives the valve stem to rotate, the butterfly plate rotates accordingly. When the butterfly plate rotates to a position perpendicular to the fluid flow direction, the valve is in a closed state, which can effectively block the passage of fluid; when the butterfly plate rotates to a position parallel to the fluid flow direction, the fluid can pass through the valve smoothly after the valve is opened. This opening and closing method results in low resistance and low flow loss when fluid passes through the valve, which is conducive to improving the operating efficiency of the system.

In terms of hygienic performance, the surface undergoes fine polishing treatment, and the polished surface has low roughness, usually achieving a mirror effect. This smooth surface is not only easy to clean but also can effectively prevent the adhesion and proliferation of microorganisms. In the food and pharmaceutical industries, the hygiene and safety of products are crucial; any minor pollution may lead to product quality problems and even safety accidents.

Sealing performance is another key indicator of stainless steel sanitary butterfly valves. It adopts a special sealing structure, commonly including two forms: soft seal and metal seal. Soft seals usually use elastic materials such as rubber and PTFE as sealing elements. These materials have good elasticity and sealing performance, can achieve reliable sealing effect at low pressure, and can effectively prevent fluid leakage. Metal seals are suitable for harsh working conditions such as high temperature and high pressure. They achieve sealing through close contact between metals, having higher temperature and pressure resistance. Regardless of the sealing form, it can ensure good sealing under various working conditions, prevent fluid leakage, and ensure the normal operation of the production system.

The stainless steel sanitary butterfly valve has various operation methods, and manual, pneumatic, or electric operation can be selected according to different usage requirements. Manual operation is simple and direct, suitable for occasions with low automation requirements; pneumatic operation has the advantages of fast response speed and reliable action, can quickly realize the opening and closing of the valve, and is suitable for occasions requiring frequent operation; electric operation can realize automatic control of the valve through remote control, improving the level of production automation and efficiency. In practical applications, users can choose the appropriate operation method according to their own production processes and equipment configurations.

In terms of installation and maintenance, the stainless steel sanitary butterfly valve is convenient. It has flexible installation methods, such as flange connection and wafer connection, which can be easily connected to the pipeline system. During installation, attention should be paid to the installation direction and position of the valve to ensure that the valve can be opened and closed normally, and that the sealing performance of the valve is not affected. In daily maintenance, it is only necessary to regularly clean and inspect the valve, check whether the sealing elements are worn, whether the valve stem is flexible, etc. If problems are found, they should be replaced or repaired in a timely manner. This simple maintenance method reduces the maintenance cost of enterprises and improves the efficiency of equipment use.

What are Stainless Steel Sanitary Butterfly Valves?

What are Stainless Steel Sanitary Butterfly Valves?

What are Sanitary Pneumatic Diaphragm Valves?

What are Sanitary Pneumatic Diaphragm Valves?

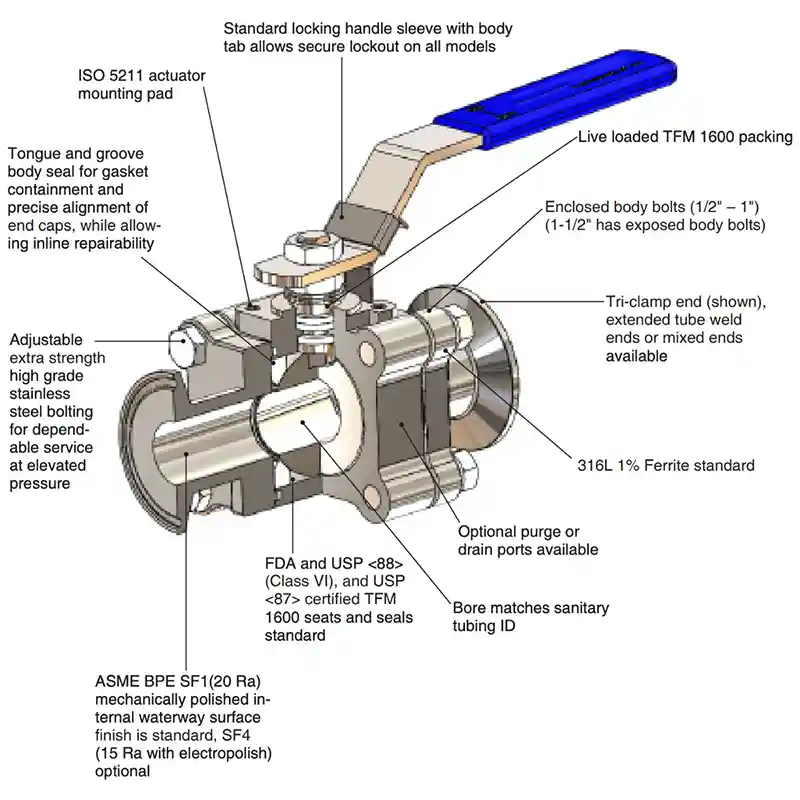

Structure of Sanitary Ball Valves with Clamp Ends

Structure of Sanitary Ball Valves with Clamp Ends

How to operate a sanitary ball valve?

How to operate a sanitary ball valve?