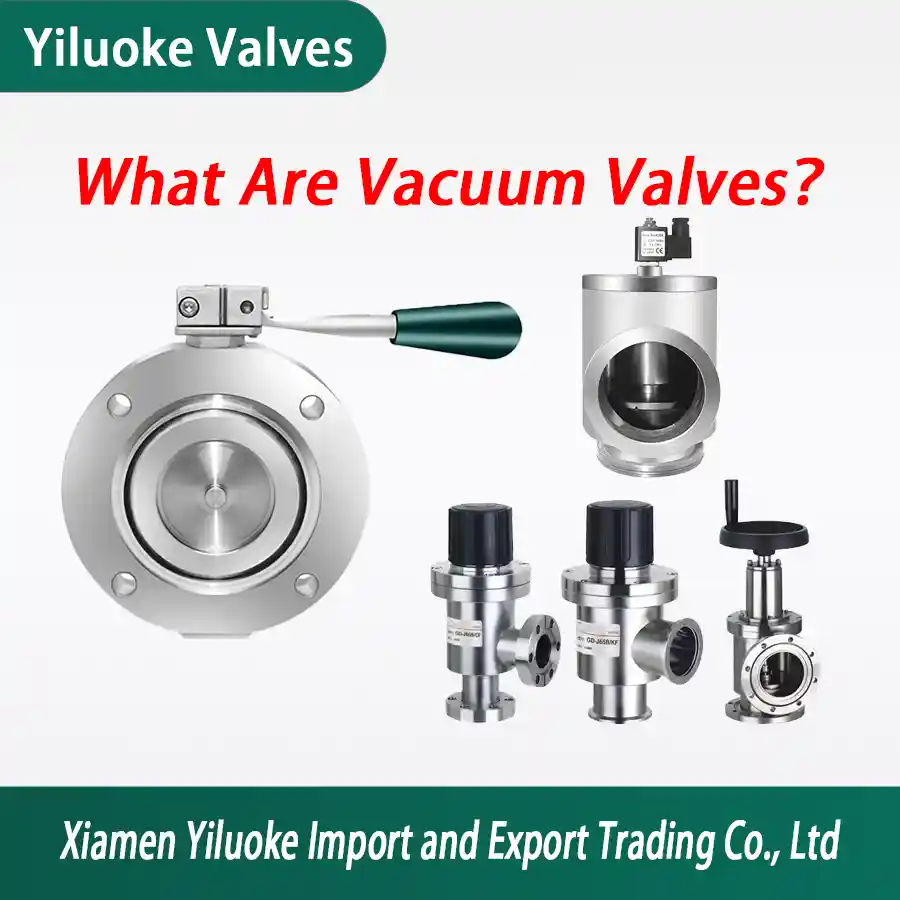

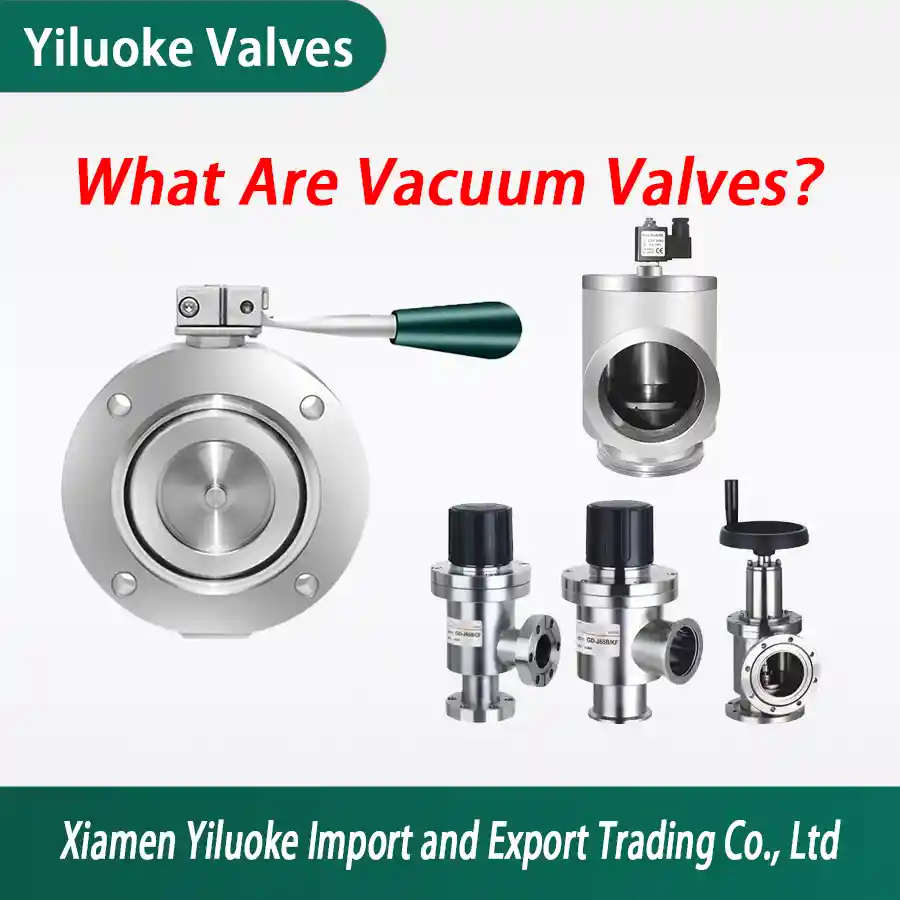

What are Vacuum Valves?

Vacuum Valves: Overview, Classification, Features, Advantages & Disadvantages

Vacuum valves are components in vacuum systems used to change gas flow direction, adjust gas flow rate, and cut off or connect pipelines.

Overview

Vacuum valves, high vacuum valves, and ultra-high vacuum valves can be grouped by medium pressure, with distinct classification standards and application scenarios. They are widely used in various industrial fields due to their flexible control capabilities and reliable performance.

Classification by Medium Pressure

Low Vacuum Valves: Medium pressure p = 760 ~ 1 mmHg

Medium Vacuum Valves: p = 1×10⁻³ mmHg

High Vacuum Valves: p = 1×10⁻⁴ ~ 1×10⁻⁷ mmHg

Ultra-High Vacuum Valves: p ≤ 1×10⁻⁸ mmHg

Types of Vacuum Valves

Vacuum Ball Valves, Vacuum Butterfly Valves, Vacuum Gate Valves, Vacuum Diaphragm Valves, Vacuum Globe Valves, Vacuum Regulating Valves, Vacuum Gate Valves, Vacuum Flap Valves, Vacuum Inflation Valves, etc.

Key Features

Simple structure, high reliability, excellent sealing performance, and strong wear resistance

High sensitivity, fast response, and easy operation

Enables continuous regulation and control of various vacuum applications

Supports automatic control for convenience and efficiency

Achieves bidirectional control, safe and reliable

Multifunctional with good flexibility

Advantages of Vacuum Valves

Simple structure, easy installation, flexible operation, durable and reliable, excellent sealing performance, and low loss

Valve cores can be made of different materials to meet various working condition requirements

High action precision ensures accurate control

Valve bodies are made of corrosion-resistant materials, suitable for use in various corrosive media

Control systems can be adjusted according to actual needs for optimal control performance

Disadvantages of Vacuum Valves

Although the structure is simple, performance is greatly affected by ambient temperature

High operating noise; sealing performance is not ideal under certain pressure conditions

Sealing performance decreases with increasing temperature, and temperature has a significant impact

Sealing performance is greatly affected by water vapor; excessive water vapor will impair valve performance

Low control precision, not suitable for occasions requiring high control accuracy

Weak corrosion resistance, cannot be used in high-corrosive medium environments

Short service life, generally only 2-3 years; prolonged use will affect performance

High requirements for design and manufacturing technology, resulting in relatively high production costs

How Are Vacuum Valves Classified?

1. Working Pressure

Based on working pressure, vacuum valves are classified into low vacuum valves, high vacuum valves, and ultra-high vacuum valves:

Low vacuum valves: Suitable for low vacuum conditions

High vacuum valves & ultra-high vacuum valves: Suitable for higher vacuum environments, with better sealing performance and lower leak rates

2. Sealing Material

According to dynamic sealing materials, vacuum valves are divided into metal-sealed and non-metal-sealed valves:

Metal-sealed valves: Adopt metal materials (e.g., metal bellows) for shaft seals, featuring low leak rates, suitable for ultra-high vacuum conditions

Non-metal-sealed valves: Use materials such as O-shaped rubber rings, with higher leak rates, suitable for high vacuum conditions with low vacuum requirements

3. Body Material

Vacuum valves can be classified by body material, with common options including:

Stainless Steel

Carbon Steel

Aluminum Alloy

The choice of material depends on specific application environments and requirements.

4. Structural Characteristics

Based on structural features, vacuum valves include:

Butterfly Valves, Ball Valves, Diaphragm Valves, Angle Valves, Gate Valves, Straight-Through Valves, Three-Way Valves, etc.

Each type is suitable for different application scenarios:

Butterfly Valves: Ideal for quick fluid cutoff

Diaphragm Valves: Suitable for occasions requiring high fluid sealing performance

5. Transmission Principle

According to transmission principle, vacuum valves are classified into:

Manual Valves

Pneumatic Valves

Electric Valves

Solenoid Valves

Pneumatic valves: Usually use electromagnetic pilot control for cylinder actuation

Electric valves: Can be operated manually or electrically; switch to manual mode during power outages

What are Vacuum Valves?

What are Vacuum Valves?

What are U-Type Sanitary Diaphragm Valves?

What are U-Type Sanitary Diaphragm Valves?

What are Stainless Steel Sanitary Butterfly Valves?

What are Stainless Steel Sanitary Butterfly Valves?

What are Sanitary Pneumatic Diaphragm Valves?

What are Sanitary Pneumatic Diaphragm Valves?