How to Use Steam Traps Correctly?

How to Use Steam Traps Correctly

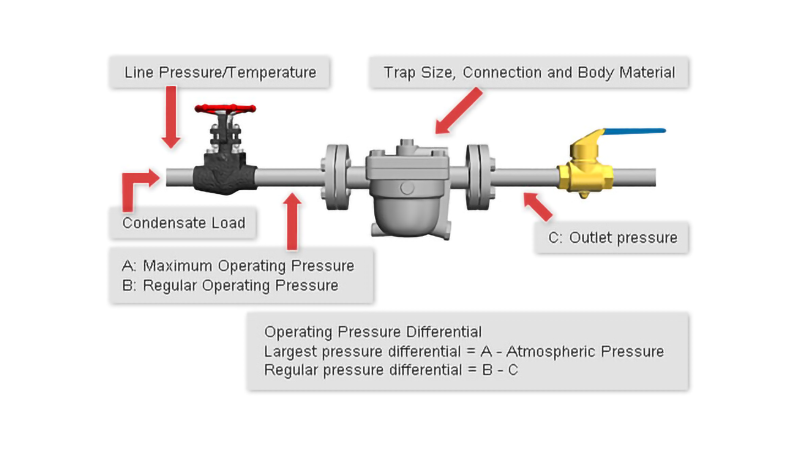

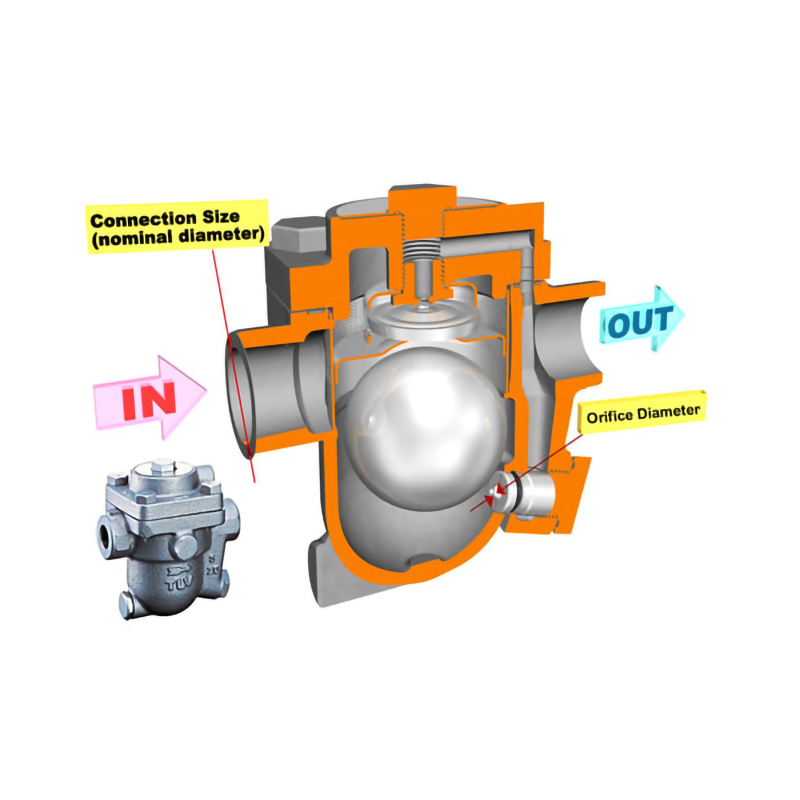

When selecting a steam trap, it is necessary to match the mechanical type according to its own characteristics to achieve the optimal drainage effect. The instructions on how to select a suitable steam trap are as follows:

Incorrect Installation of Steam Traps

It must be kept in mind that the steam trap must be installed in accordance with the markings on the valve body or the equipment operation requirements during installation. Secondly, the steam trap should preferably be installed at a position lower than the condensate outlet. In special cases where the steam trap has to be installed higher than the water outlet, an elbow pipe should be added at the lifting part between the steam trap and the water outlet, and a thin pipe should be inserted into the elbow pipe, so as to ensure that the steam pressure pushes the water upward and lifts it into the steam trap through the water seal pipe.

If an inverted bucket steam trap is used under such installation conditions, a check valve must be installed in front of the steam trap to prevent the water seal inside the inverted bucket steam trap from being damaged by siphonage. When installing a mechanical steam trap, it must be installed as close to the water outlet as possible, otherwise steam lock is likely to occur. If it is impossible to install it close to the water outlet, a float steam trap with an air lock elimination device must be selected.

In addition, when installing a thermostatic steam trap, if it is necessary to ensure that there is no condensate remaining in the heating pipe at all times, remember to reserve a pipeline of at least 1 meter in length in front of the steam trap, and this section of the pipeline shall not be insulated. Each heater needs to be equipped with an independent steam trap, and multiple heaters are forbidden to share a single steam trap to avoid reducing the heat transfer efficiency.

Sewage, Water Hammer and Freezing

Dirt, water hammer and freezing may all cause the steam trap to fail. Therefore, a strainer must be installed unless the steam trap is equipped with a built-in filter screen, so as to prevent dirt from entering the valve body. After a water hammer occurs, efforts should be made to identify and completely eliminate the root cause; if it cannot be solved temporarily, a steam trap with a more robust structure must be selected, such as a steam trap with a steel valve body, which is not easy to be damaged even if freezing occurs.

Air in the Steam Space

The accumulation of air and non-condensable gases in the steam space is the main cause of reduced heat exchange efficiency of equipment. Although steam traps have good air exhaust function, they can only discharge the air that reaches their water inlet. If air accumulates in the dead corners inside the heat exchange equipment, an automatic air vent must be installed, and the automatic air vent should be installed at the highest point of the pipeline. The specific installation position and quantity shall be determined according to the actual process of the steam pipeline.

Excessively High Back Pressure

The inlet pressure of the steam trap must always be higher than the back pressure at the water outlet, otherwise water accumulation will start inside the heat exchange equipment. At the same time, excessively high back pressure will reduce the drainage capacity of the steam trap and slow down the air exhaust speed, which is particularly obvious when the equipment is started up.

The most common cause of excessively high back pressure is the elevated drainage pipeline at the rear end of the steam trap, which can be solved by installing a pump to transport the condensate. Another cause is the secondary steam generated in a condensate recovery system with an undersized design. Therefore, the condensate recovery pipeline must be professionally calculated and designed, and the secondary steam can also be recovered and reused.

Steam Lock

Steam lock often occurs under the working condition that the pipeline between the condensate collection point and the steam trap inlet is surrounded by high-temperature steam (such as the siphon pipe inside a drying drum). In addition, this phenomenon will also occur when the steam trap is installed far away from the on-site equipment and the connected pipeline is exposed to a high-temperature environment.

When the steam trap is installed in this way, the steam in the pipeline cannot condense quickly, which further hinders the condensate from flowing to the steam trap and forms water accumulation blockage in the steam space. This phenomenon is very similar to the air blockage principle formed by air accumulation in the water system, and such problems can be solved by installing an air lock eliminator.

Centralized Drainage

Centralized drainage refers to using only one steam trap to drain water for two or more heat exchange equipments. When the condensate generated by one of the equipments flows into the steam trap and completes the discharge, steam will immediately enter the steam trap and cause the steam trap to close; the condensate generated by other equipments cannot be discharged due to the formed steam lock, which will subsequently lead to water accumulation blockage and greatly reduce the working efficiency of the heat exchange equipment.

If multiple heat exchange systems with different working pressures share a single steam trap for centralized drainage, the above problems will be further aggravated. Therefore, the centralized drainage method must be completely avoided.

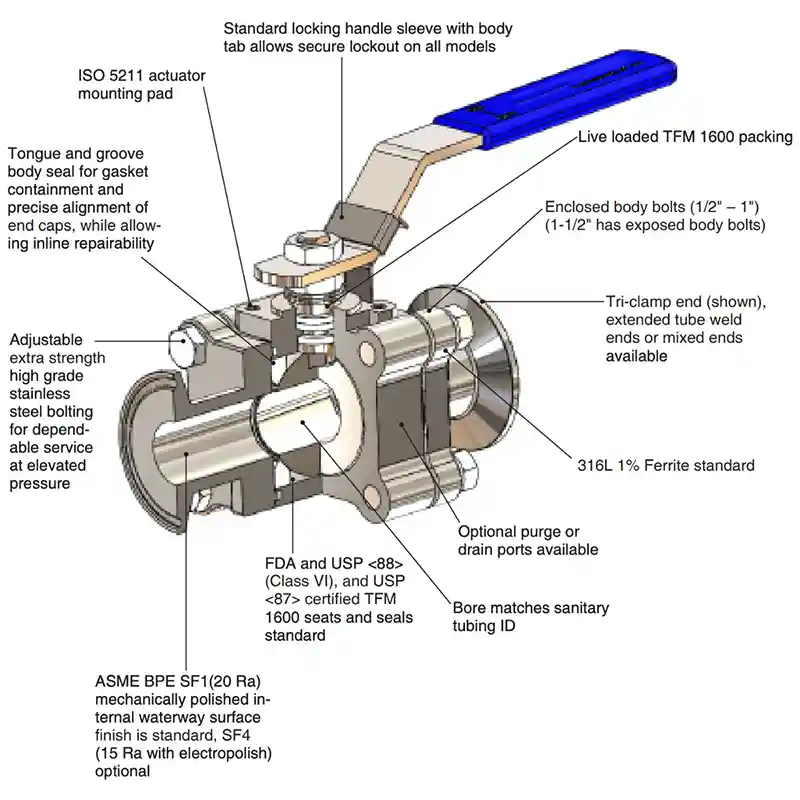

How to operate a sanitary ball valve?

How to operate a sanitary ball valve?

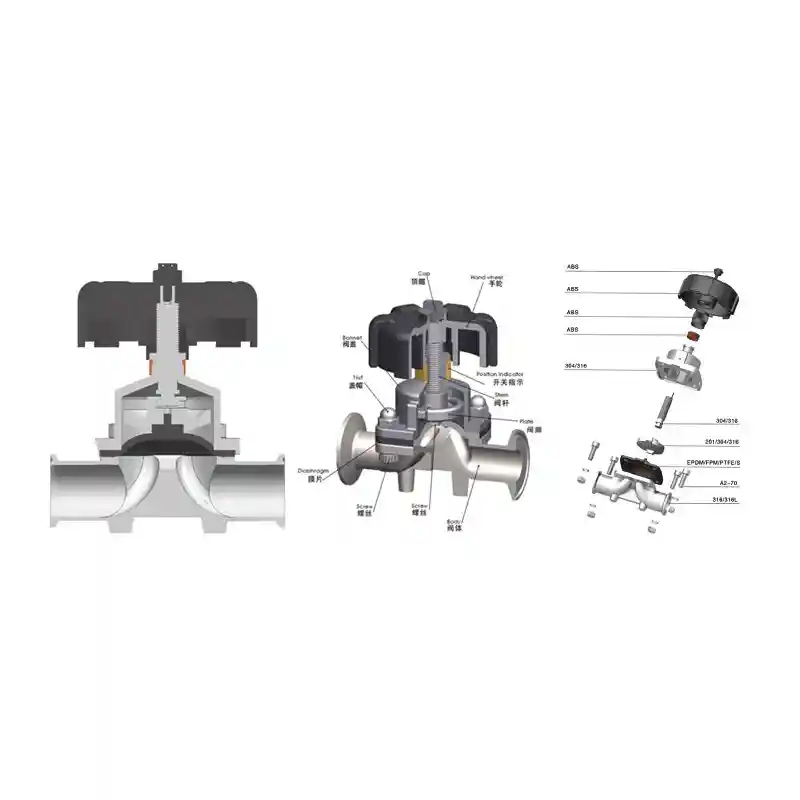

How to Correctly Use Stainless Steel Sanitary Diaphragm Valves?

How to Correctly Use Stainless Steel Sanitary Diaphragm Valves?

What is a Sanitary Pressure Regulator?

What is a Sanitary Pressure Regulator?

What Are Sanitary Valves?

What Are Sanitary Valves?