What Are Pneumatic Angle Seat Valves?

What Are Pneumatic Angle Seat Valves?

The pneumatic angle seat valve is a type of valve commonly used in automatic control systems. It mainly realizes the opening, closing and regulation of fluid through a pneumatic actuator. Its unique structure and working method have enabled it to be widely used in multiple industries. The working principle of the pneumatic angle seat valve will be detailed below.

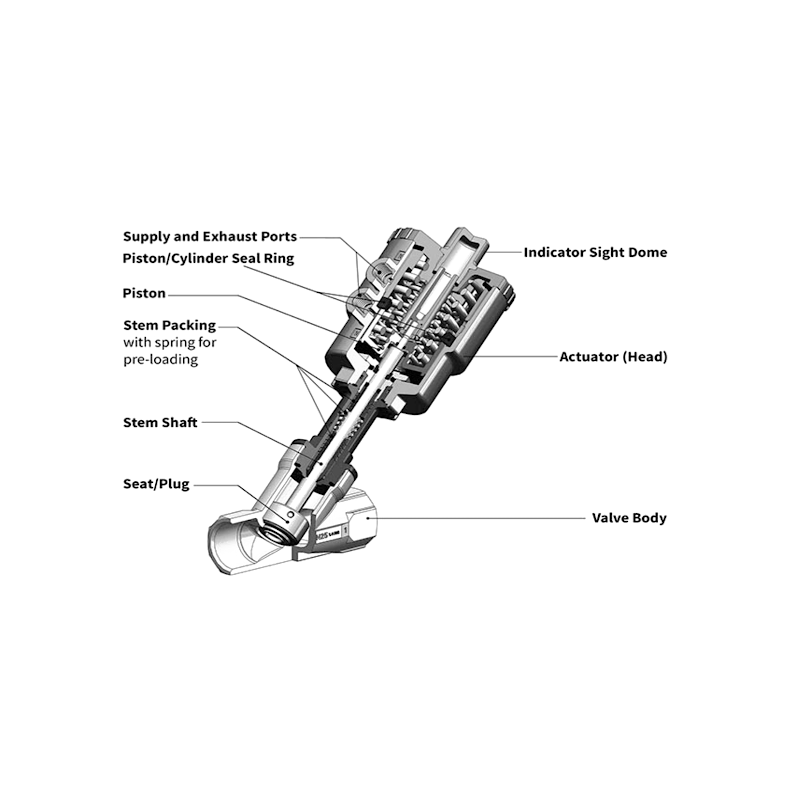

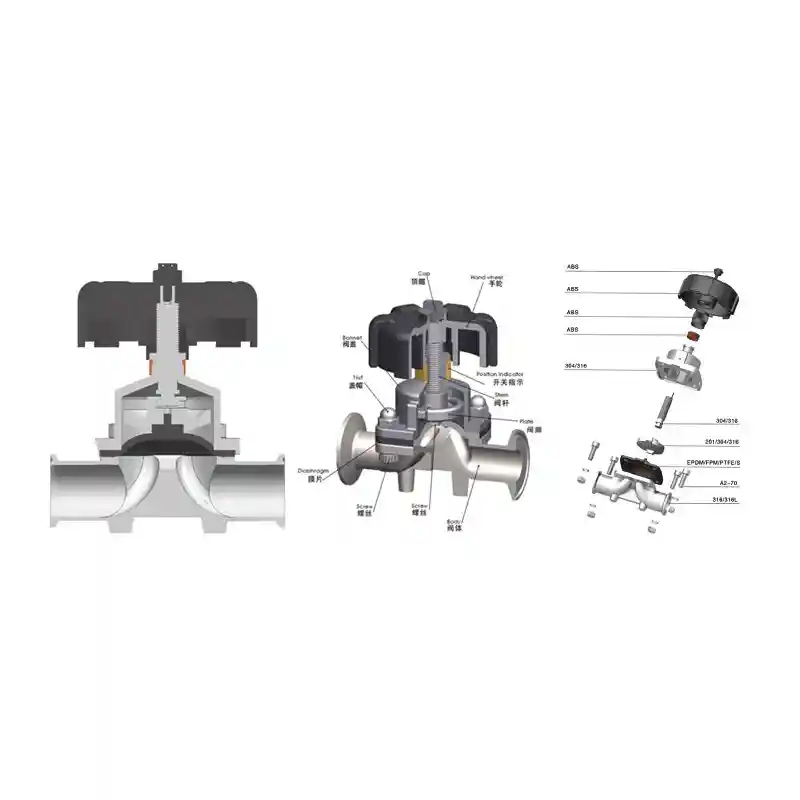

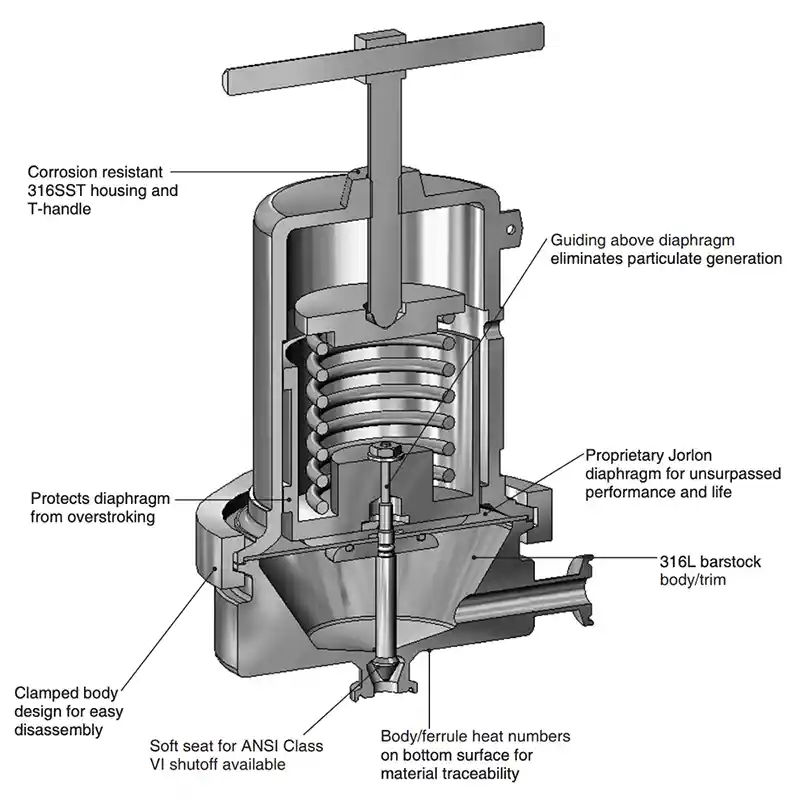

I. Basic Structure

The pneumatic angle seat valve is composed of a valve body, valve core, pneumatic actuator, spring, seals and other components. The valve body is usually made of corrosion-resistant materials such as stainless steel or cast steel to adapt to different working environments. The shape of the valve core can be designed as straight-through or angle type to ensure small pressure loss when fluid flows.

II. Working Process

The working process of the pneumatic angle seat valve is mainly divided into several steps:

Air Supply: The operation of the pneumatic angle seat valve relies on compressed air as the power source. The air supply system delivers compressed air to the pneumatic actuator through pipelines.

Signal Input: In the automatic system, the controller will issue command signals according to operational requirements to determine the opening or closing of the valve. These signals are transmitted to the pneumatic actuator through electrical or pneumatic means.

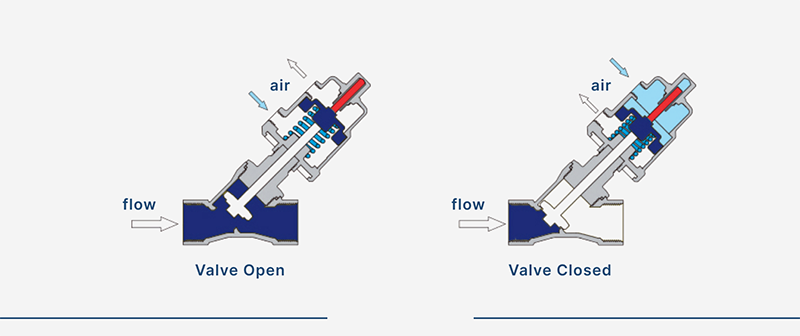

Action of Pneumatic Actuator: After the control signal reaches the pneumatic actuator, the air pressure inside the actuator will change. When air pressure enters one side of the actuator, it pushes the diaphragm or piston to move upward, driving the valve core to rise, and the valve opens to allow fluid to pass through.

Fluid Flow Control: When the valve is open, fluid flows in from the inlet of the valve and out through the channel of the valve core. The design of the pneumatic angle seat valve ensures the flow direction and flow rate of the fluid, and when necessary, precise control of the flow rate can be achieved by adjusting the air pressure.

Valve Closing: When it is necessary to close the valve, the control system will cut off the air supply, and the pressure inside the pneumatic actuator drops rapidly. At this time, the action of the spring will press the valve core back to the closed position, thereby stopping the fluid flow. This design ensures that the valve can be closed safely and reliably when the air supply is lost.

III. Feedback and Regulation

Some high-end pneumatic angle seat valves are equipped with position feedback devices, which can real-time monitor the opening state of the valve. Through sensors, the actual position of the valve is fed back to the control system, ensuring that the system can accurately judge the working state of the valve and make necessary adjustments. In addition, some models also have proportional control functions, which can realize more refined flow regulation.

IV. Advantages

The working principle of the pneumatic angle seat valve endows it with some significant advantages:

Fast Response: Due to the rapid switching capability of the pneumatic actuator, the pneumatic angle seat valve performs excellently in working conditions that require frequent operations.

High Durability: The pneumatic angle seat valve has a simple structure and low failure rate, making it suitable for long-term operation and reducing maintenance costs.

Wide Application Range: It can be applied to various fluids, including gases, liquids and granular materials, to meet different industrial needs.

High Safety: When the air supply fails or an abnormality occurs, the pneumatic angle seat valve can be closed quickly to prevent accidents and improve the safety of the entire system.

With its efficient and reliable working principle, the pneumatic angle seat valve plays an important role in modern industry. Driven by the pneumatic actuator, the pneumatic angle seat valve can not only realize rapid fluid control, but also ensure safe and stable operation under various complex working conditions. With the development of technology, the performance and application fields of the pneumatic angle seat valve will continue to expand, providing stronger support for industrial automation.

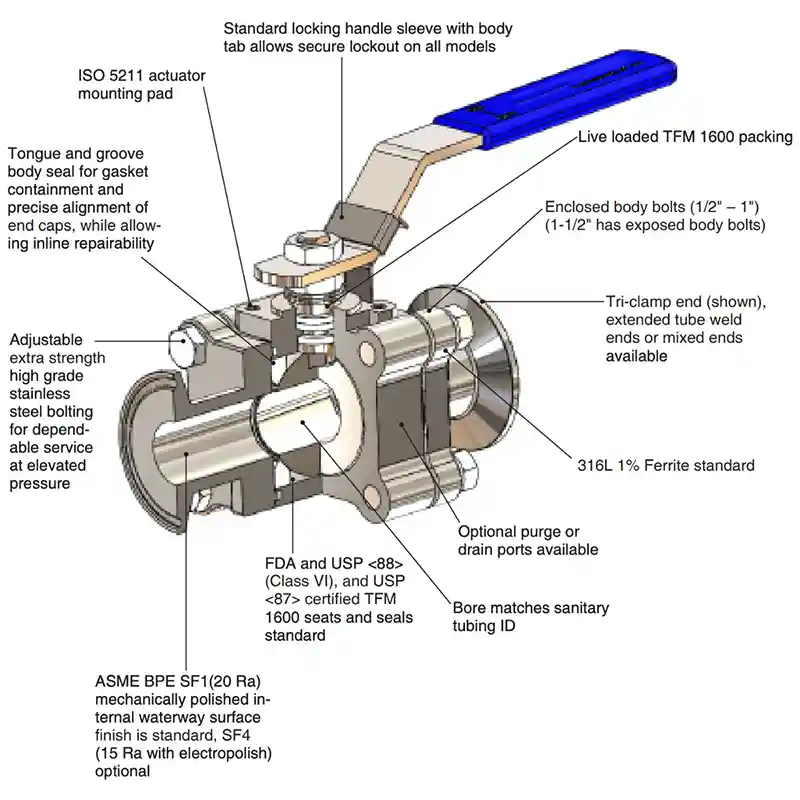

How to operate a sanitary ball valve?

How to operate a sanitary ball valve?

How to Correctly Use Stainless Steel Sanitary Diaphragm Valves?

How to Correctly Use Stainless Steel Sanitary Diaphragm Valves?

What is a Sanitary Pressure Regulator?

What is a Sanitary Pressure Regulator?

What Are Sanitary Valves?

What Are Sanitary Valves?