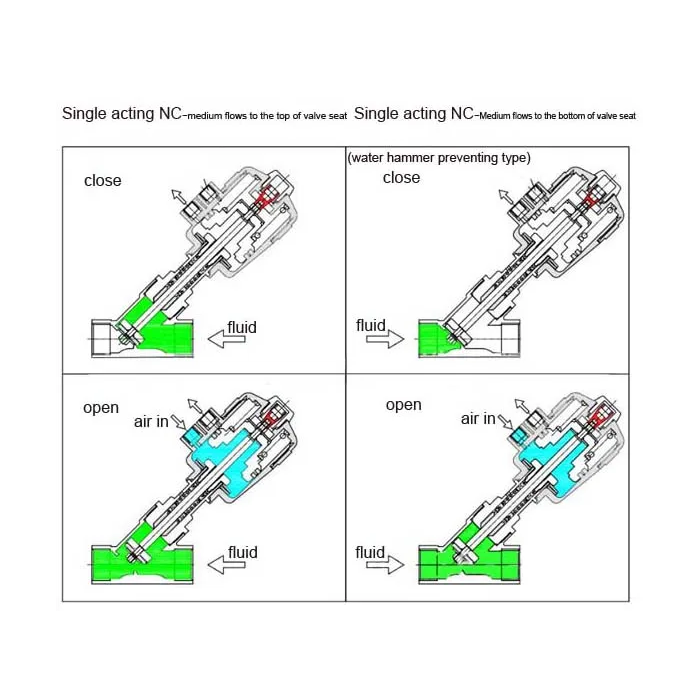

How to Use Pneumatic Angle Seat Valve?

How to Use Pneumatic Angle Seat Valve & Maintenance Guide

Due to its sensitive response, accurate action, ability to maintain flow rate and save space, the pneumatic angle seat valve is widely used in many industries. Of course, to ensure these advantages are stably exerted during use, operators need to maintain and correctly use the pneumatic angle seat valve. Next, we will specifically analyze the use and maintenance of the pneumatic angle seat valve.

I. Use of Pneumatic Angle Seat Valve

Test Run Work: Check if the connectors of the pneumatic angle seat valve are loose; Turn the coupling by hand to rotate the rotor several times to see if the unit runs flexibly, if there is any noise or uneven weight feeling, so as to judge whether there is foreign matter in the valve, whether the shaft is bent, whether the seal is installed correctly, etc.; Check if the surface of the unit is clean;

Manual Start: Open the pneumatic angle seat valve, start the motor, and gradually open the outlet valve to meet the working condition requirements when the pressure rises and the unit is confirmed to run stably;

Operation Inspection: During normal frequency conversion operation, regularly check and record the readings of ammeters, voltmeters, inlet and outlet vacuum gauges, pressure gauges, flow meters and other instruments. Check if the vibration, noise, temperature rise of the unit are normal. There should be no obvious engine oil leakage at the shaft seal;

Normal Shutdown: Close the stainless steel angle seat valve to lighten the load of the unit, then stop the motor.

II. Maintenance of Pneumatic Angle Seat Valve

Every 500 hours of operation of the pneumatic angle seat valve, loosen the plug on the seal seat and use a syringe to extract the residual engine oil in the valve body;

When the mechanical noise of the motor increases and the temperature rise at the bearing is abnormal, check the lubrication of the motor bearing;

If oil leakage is found at the seal seat of the pneumatic angle seat valve, loosen the plug on the seal seat and run the angle seat valve. If oil overflows and there is an oil smell, it can be determined that the mechanical seal has failed. Stop the stainless steel angle seat valve and quickly replace the mechanical seal.

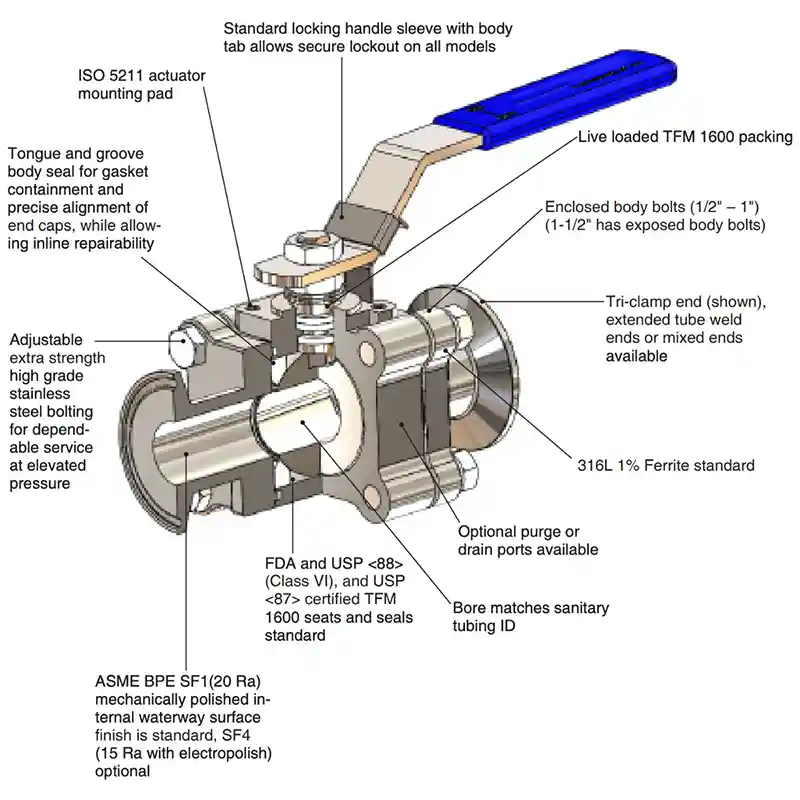

How to operate a sanitary ball valve?

How to operate a sanitary ball valve?

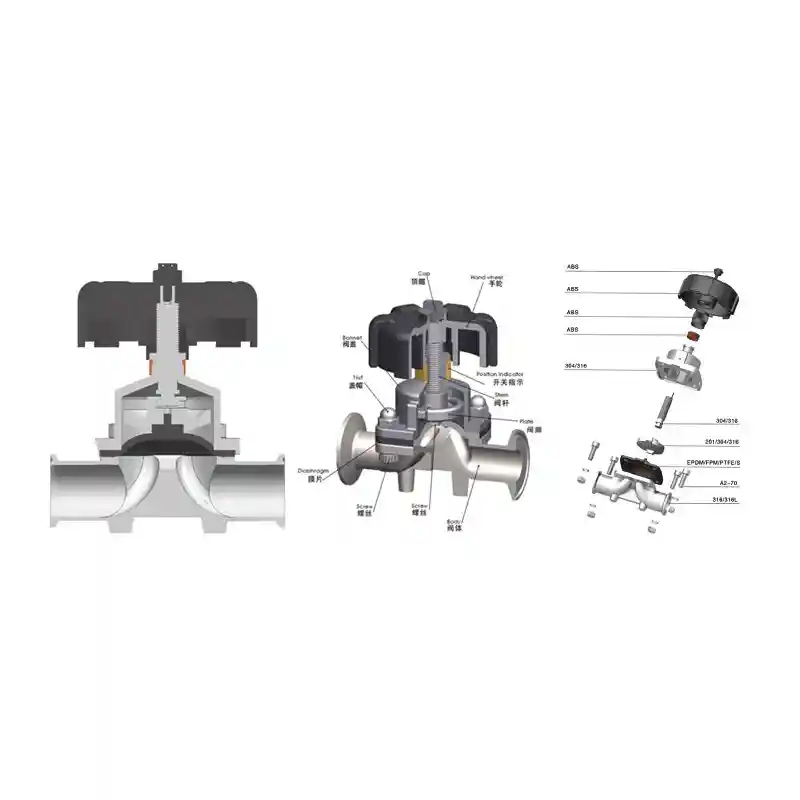

How to Correctly Use Stainless Steel Sanitary Diaphragm Valves?

How to Correctly Use Stainless Steel Sanitary Diaphragm Valves?

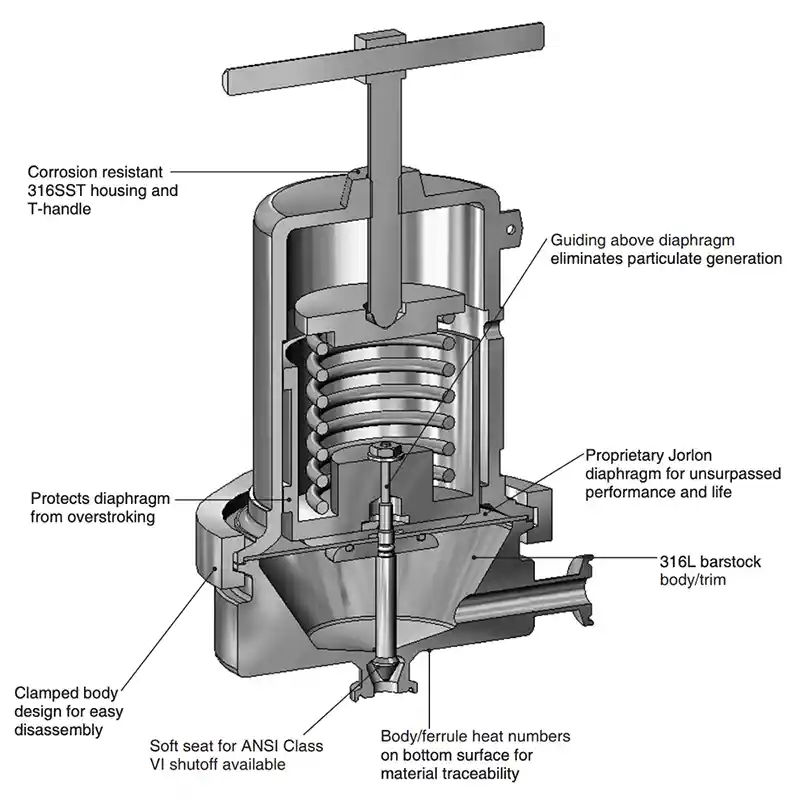

What is a Sanitary Pressure Regulator?

What is a Sanitary Pressure Regulator?

What Are Sanitary Valves?

What Are Sanitary Valves?