Inverted Bucket Steam Trap Working Principle

Inverted Bucket Steam Trap Working Principle

Different from the free float type, the inverted bucket steam trap operates on the principle of the density difference between condensed water and steam. Its internal structure consists of an inverted bucket (as the liquid level sensing element with a downward opening) connected by a lever system, which overcomes steam pressure to switch the valve on and off. The specific working cycle is as follows:

Startup Phase

When the device is first started, air and low-temperature condensed water are present in the pipeline. At this stage, the steam trap is fully open, allowing rapid discharge of air and low-temperature condensed water, which helps the device quickly raise its temperature to the working level.

Steam Entry & Valve Closing

When steam enters the inverted bucket, the bucket generates upward buoyancy. The lever connected to the inverted bucket drives the valve core to close the valve, preventing steam leakage.

Condensation & Valve Opening

There is a small hole on the inverted bucket that enables automatic air discharge. As part of the steam is discharged through this small hole, the remaining steam condenses into water. The inverted bucket then loses buoyancy and sinks downward, and the connected lever drives the valve core to open the valve, discharging the condensed water.

Cyclic Operation

When steam enters the inverted bucket again, the valve closes once more. This cyclic process realizes intermittent but efficient drainage of condensed water.

Below is the animated working principle of the inverted bucket steam trap:

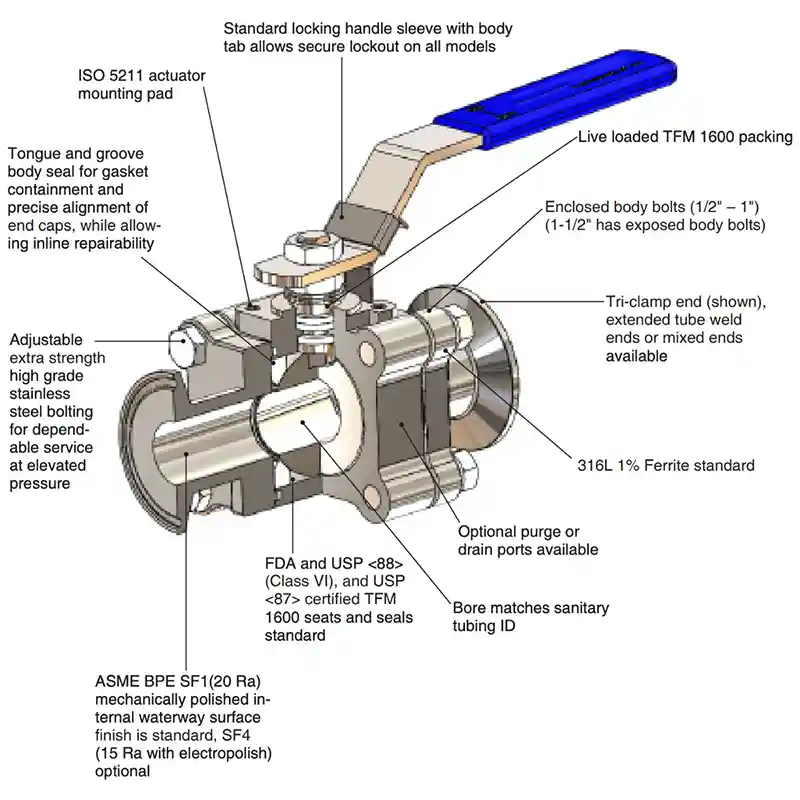

Structure of Sanitary Ball Valves with Clamp Ends

Structure of Sanitary Ball Valves with Clamp Ends

How to operate a sanitary ball valve?

How to operate a sanitary ball valve?

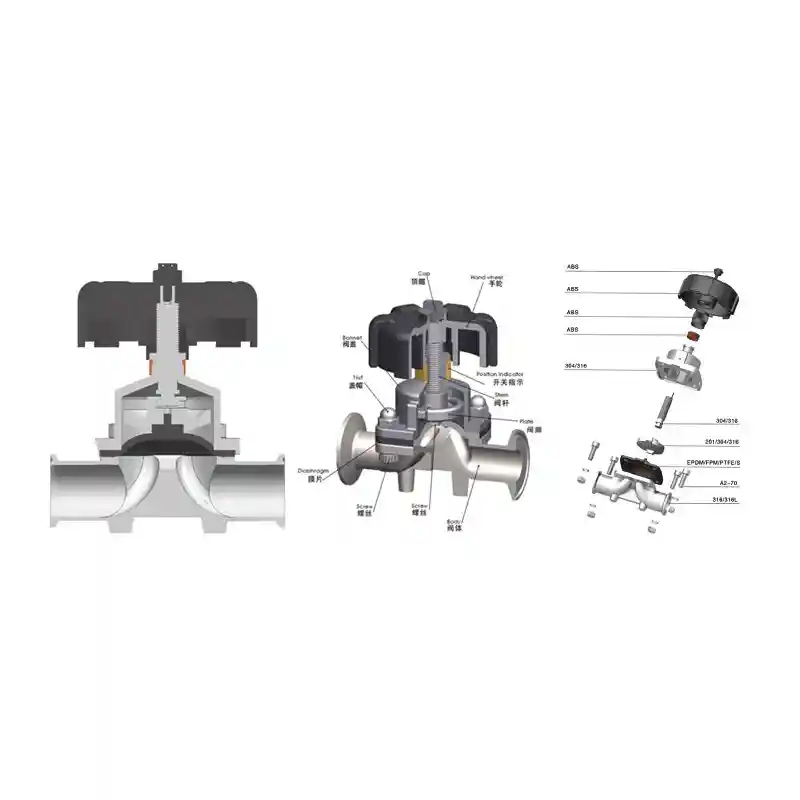

How to Correctly Use Stainless Steel Sanitary Diaphragm Valves?

How to Correctly Use Stainless Steel Sanitary Diaphragm Valves?

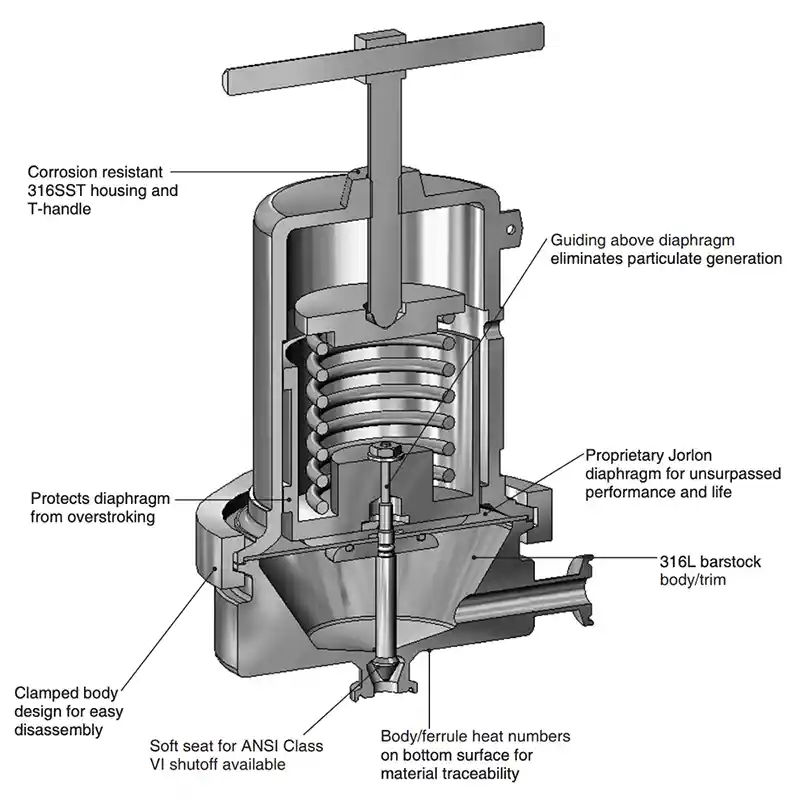

What is a Sanitary Pressure Regulator?

What is a Sanitary Pressure Regulator?