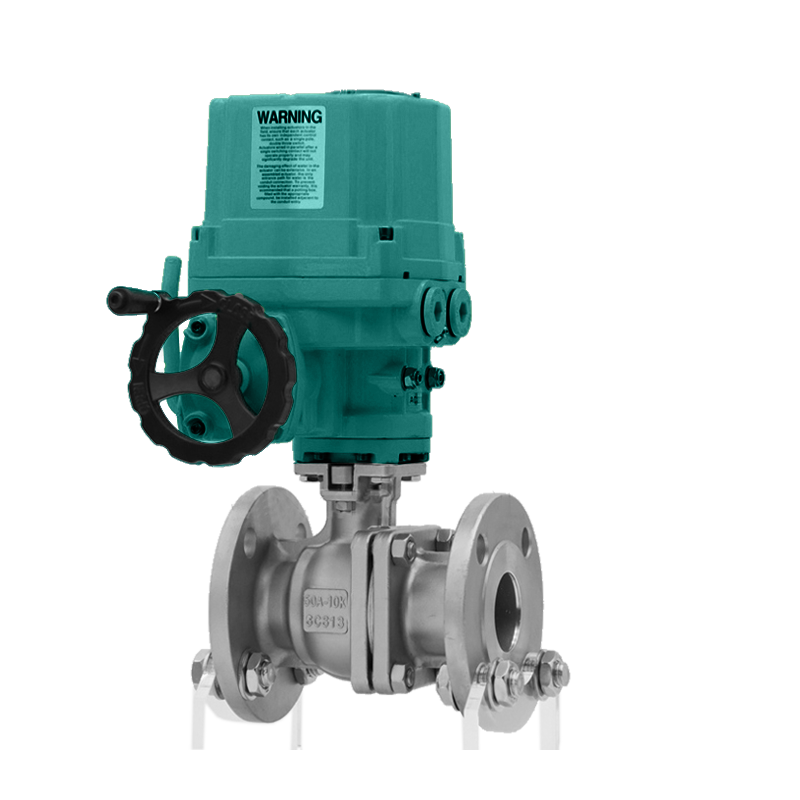

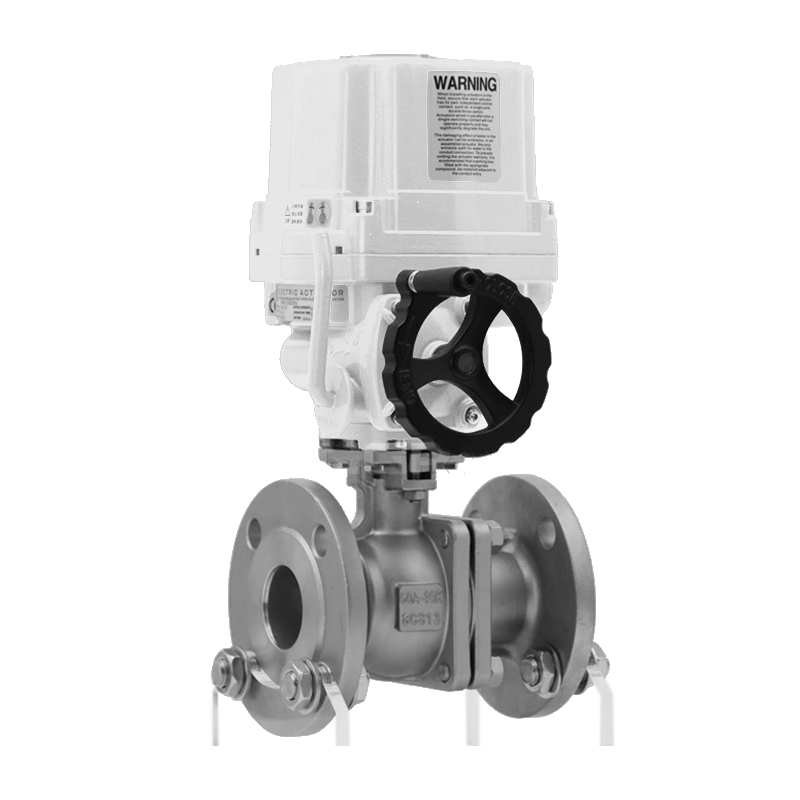

Explosion-Proof Electric Actuated Ball Valves

Explosion-Proof Electric Actuated Ball Valves: Structure, Features & Technical Parameters

An explosion-proof Electric Actuated Ball Valve is a type of valve where the ball rotates 90° around an axis perpendicular to the passage. Composed of a rotary explosion-proof angular stroke electric actuator and an O-type valve structure, it belongs to the high-performance rotary type regulating or on-off valve category. It accepts the input and output of current signals or voltage signals from industrial automation control (DCS, PLC system) instruments, and can realize proportional regulation or two-position on-off control of fluid media in process pipelines, thereby achieving automatic control of parameters such as flow rate, pressure, temperature, and liquid level of the fluid media.

Structural Features

Low Fluid Resistance: It has the smallest fluid resistance among all valve types. Powered by AC220V, AC380V, or DC24V power supply voltage, it can be controlled to operate by accepting current signals or voltage signals (4-20mA, 0-10mA, or 1-5VDC). The torque output by the angular stroke rotates the ball 0-90° to complete the opening and closing action or regulating action.

Full Electronic Electric Actuator: Adopting an electromechanical integration mechanism, it has functions such as in-machine servo operation, opening signal position feedback, position indication, and manual operation. It has strong functions, reliable performance, and simple connection. By inputting current signals or voltage signals, the rotation angle of the ball core (0-90°) is changed to realize proportional regulation action.

Smooth Ball Core Channel: The channel of the ball core is flat and smooth, which is not easy to deposit media and can perform pipeline pigging. It has a simple structure, light weight, and good sealing performance. It is especially suitable for occasions requiring zero leakage.

Technical Parameters

Product Name: Explosion-Proof Electric Actuated Ball Valve

Valve Body Material: Stainless Steel CF8/CF8M

Connection Method: Flange Type

Nominal Diameter: DN15~DN400

Drive Method: Electric

Applicable Media: Water, Gas, Oil, etc.

Applicable Temperature: -20~250℃

Nominal Pressure: 1.6MPa-6.4MPa

Design and Manufacturing Standards: GB/T 12237; ASME B16.34; API608

Flange Standards: GB/T 9113; ASME B16.10

Structure Length Standards: GB/T 12221; ASME B16.10; API 6D

Fire Protection Standards: API 6FA; API 607; JB/T 6899

Actuator Type: Compact Explosion-Proof Type, OHQ Explosion-Proof Type

Control Mode: On-Off Type, Regulating Type

Power Supply Voltage: 110VAC; 220VAC; 380VAC; 50/60Hz

Input Signal: 4-20mADC or 1~5VDC

Output Signal: 4-20mADC

Protection Level: IP65; IP67; IP68

Explosion-Proof Level: Exd II BT4; Exd II CT6

Ambient Temperature: -25℃~55℃

Ambient Humidity: 10~90%RH

Stroke: 90°~120°/±10°

Action Time: 7s-120s

Insulation Resistance: 100MΩ (500VDC)

Motor Protection: Overheat Protector (Automatic Recovery Type)

Manual Control: Removable Wrench/Handwheel

Torque Range: 7N.m-2000N.m

Manufacturing Standards: National Standard GB/Mechanical Department JB/Chemical Department HG/American Standard ANSI/API/Japanese Standard JIS/German Standard DIN/Other Customized Standards