High-Temperature and High-Pressure Solenoid Valves

High-Temperature and High-Pressure Solenoid Valves: Definition, Fields, Features, Principle & Parameters

1. Definition

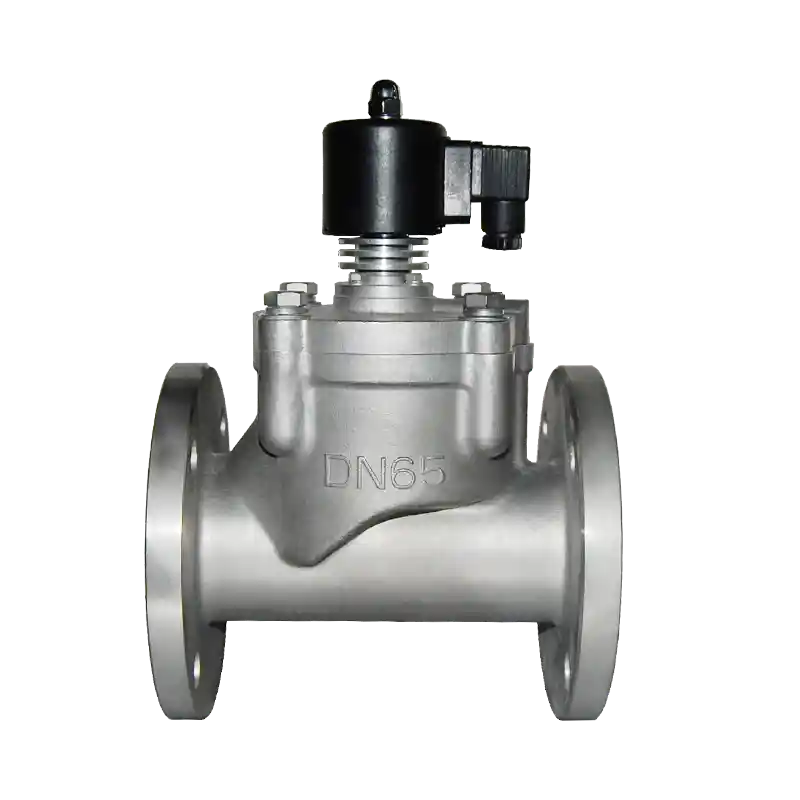

High-temperature and high-pressure solenoid valves adopt a piston structure in the inner cavity, featuring stable performance and excellent sealing. They are mainly used for the automatic control of pipelines carrying medium and high-pressure steam, high-pressure gases, heat transfer oil, etc.

2. Application Fields

Widely applied in aerospace, marine heavy industry, nuclear industry, petrochemicals, power industry, chemical industry, light industry, machinery, scientific research, drying equipment, food industry, medical industry, cleaning equipment, and other fields involving automatic control of steam pipelines.

3. Product Features

Corrosion Resistance: Key components such as valve plugs and valve bodies are made of stainless steel 304 and 316, ensuring superior corrosion resistance.

Wear Resistance: Rational material selection is adopted. The fluid lubrication effect is cleverly utilized between the valve plug and the valve, reducing wear and significantly extending service life.

High-Pressure Resistance: Adopts a pilot piston structure, utilizing the principle of effectively controlling action under high pressure and enabling easy opening under low pressure.

4. Working Principle

4.1 Normally Closed (NC)

When the coil is energized, the electromagnet core is attracted, the pressure relief hole opens, and the main piston is pushed by the medium pressure to open the main valve port, allowing medium circulation. When the coil is de-energized, the main valve port closes, and the medium flow is cut off.

4.2 Normally Open (NO)

When the coil is energized, the electromagnet core is attracted, the pressure relief hole closes, and the main piston is pushed by the medium pressure to close the main valve port, cutting off medium flow. When the coil is de-energized, the main valve port opens, and the medium circulates.

5. Technical Parameters

Parameter Name | Specifications |

|---|---|

Operation Method | Normally Closed (NC): Open when energized, closed when de-energized; Normally Open (NO): Open when de-energized, closed when energized |

Medium Temperature | -200℃, -100℃, -40℃, ≤100℃, ≤200℃, ≤300℃, ≤600℃ |

Applicable Medium | Water, diesel, carbon dioxide, air, natural gas, nitrogen, and other normal-temperature liquids or gases |

Nominal Diameter (mm) | 1mm-300mm |

Connection Size | 1/8"-12" |

Pressure (Mpa) | 0.1MPa~45.0MPa |

Power | AC: 15W, DC: 18W |

Voltage Deviation | Allowable fluctuation of ±10% |

Valve Body Material | Forged stainless steel (304, 316, 316L) |

Operating Environment Temperature | -20~60℃ |

Electrical Connection | Junction box and cable socket, Protection Level IP65 |

Power Supply Voltage | AC220V (50Hz/60Hz), DC24V, DC12V; other voltages available upon request |

Special Options | Waterproof, explosion-proof, manual operation function, signal feedback |

Explosion-Proof Rating | ExmI/IIT4 (encapsulated type), dIIBT4, dIICT5 (including hydrogen) |

Installation Tips | Preferred installation with the coil facing vertically upward; other installation orientations available as needed |

Note | The high-pressure valve requires a pressure difference of at least 0.3Mpa to fully open or close |