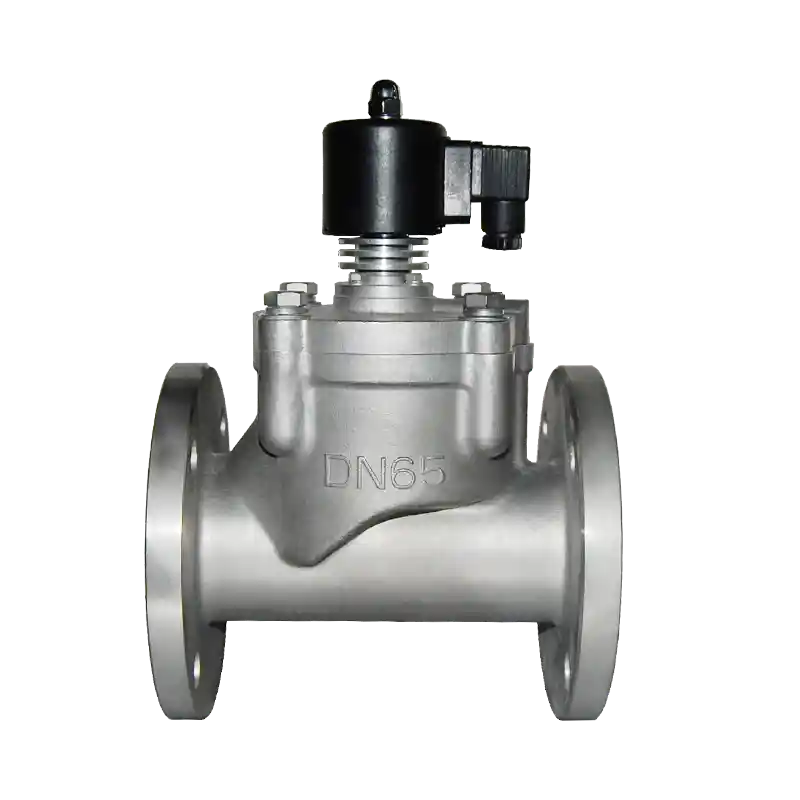

Stainless Steel Solenoid Valves

Stainless Steel Solenoid Valves: Product Overview, Features, Working Principle & Technical Parameters

1. Product Overview

All valve cores of stainless steel solenoid valves are stainless steel pistons. The piston ring will not be jammed by impurities in the fluid, featuring high dynamic sealing performance and an extra-long service life. There is no direct friction between the piston and the metal valve cavity, allowing unrestricted valve body installation. Equipped with a special energy-saving coil, it is resistant to burnout. Even after long-term inactivity, the stainless steel solenoid valve remains sensitive when restarted. The minimum starting pressure is 0.3MPa.

2. Product Features

All valve cores are stainless steel piston-type, with piston rings made of special temperature-resistant and wear-resistant materials.

No direct friction between the piston and the metal valve cavity, enabling unrestricted installation direction of the valve body.

Equipped with a special coil and an integrated heat dissipation structure, ensuring resistance to burnout.

Remains sensitive when restarted after long-term inactivity.

Minimum starting pressure: 0.3MPa.

3. Working Principle

3.1 Normally Closed (NC)

When the coil is energized, the pilot valve core is attracted, the pilot hole opens, and the upper chamber of the valve releases pressure. The piston is pushed by the medium pressure in the lower chamber, opening the solenoid valve. When the coil is de-energized, the pilot valve core resets via the spring, the pilot hole closes, and the upper chamber of the valve is pressurized through the piston orifice. With the thrust of the return spring, the valve closes.

3.2 Normally Open (NO)

When the coil is energized, the pilot hole closes, the upper chamber of the valve is pressurized through the piston orifice, and with the thrust of the return spring, the solenoid valve closes. When the coil is de-energized, the pilot valve core resets via the spring, the pilot hole opens, the upper chamber of the valve releases pressure, and the piston is pushed by the medium pressure in the lower chamber, opening the solenoid valve.

4. Technical Parameters

Parameter Name | Specifications |

|---|---|

Nominal Diameter | DN15~DN300 (G1/8"~12") |

Operation Mode | Pilot type, direct-acting type, explosion-proof type |

Operating Environment Temperature | -30—+80℃; -50—+100℃ |

Coil Operating Temperature | <+50℃, <+85℃ |

Control Mode | Normally Open (NO), Normally Closed (NC) |

International Standard Voltage | AC (380, 220, 110, 24) V; DC (220, 110, 24, 12) V |

Circulating Fluid Medium | Water, steam, oil, and other high-temperature fluids |

Circulating Fluid Temperature | <+120℃, <+200℃, <+350℃, <+450℃, <+550℃, <+800℃ |

Circulating Fluid Pressure | 64—4000bar |

Valve Body Material | Stainless steel (304, 316, 316L, etc.) |

Connection Method | Threaded (internal thread, external thread), flanged, welded, clamped |