Bimetallic Steam Trap Working Principle

Bimetallic Steam Trap Working Principle

The bimetallic steam trap operates based on the thermal expansion and contraction principle of bimetallic elements. Its working process is divided into the following stages, ensuring efficient discharge of condensed water and reliable prevention of steam leakage:

Startup Stage: When the equipment starts, air enters the steam trap. At low temperatures, the valve core remains in the open position.

Low-Temperature Condensed Water Discharge Stage: After condensed water enters the steam trap, at low temperatures, the temperature-sensitive liquid in the diaphragm element is still condensed. The valve core is fully open, and the condensed water is discharged immediately.

Temperature Rise & Valve Closing Stage: As the temperature of the condensed water entering the steam trap rises, the temperature-sensitive liquid inside the diaphragm element begins to evaporate and expand. With the increase of internal pressure, the diaphragm moves the valve core in the closing direction. Before the temperature reaches the saturation temperature, the slide valve completely closes the valve.

Cooling & Valve Reopening Stage: After the hot condensed water accumulated in the valve cools down slowly, the diaphragm contracts due to the decrease of internal pressure, the valve core opens the valve, and the condensed water continues to be discharged. The reliable sealing of the valve is ensured because there is always hot condensed water in front of the valve, realizing the separation of steam and water and avoiding steam leakage.

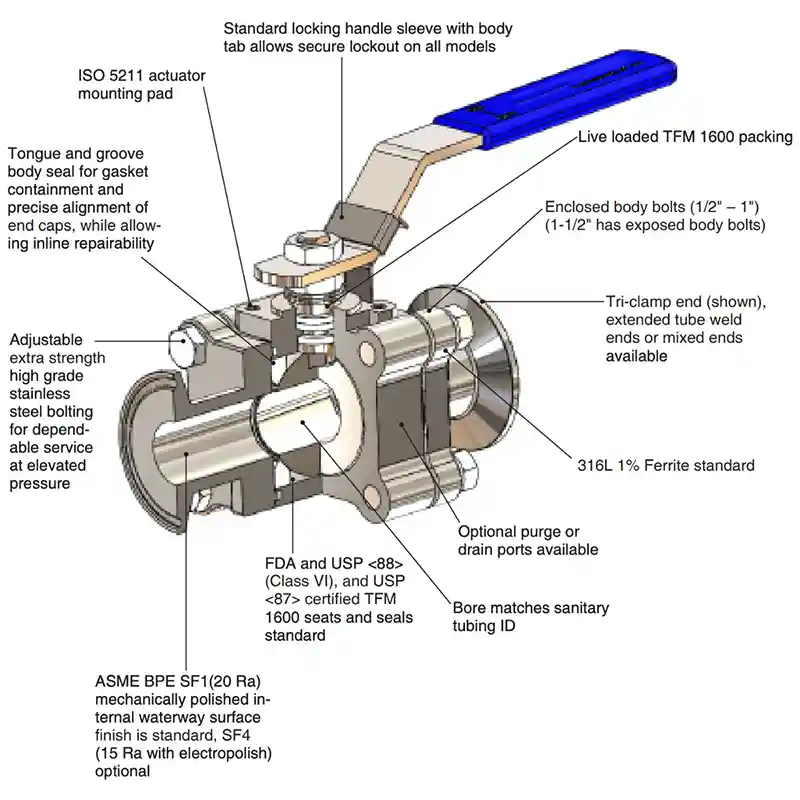

How to operate a sanitary ball valve?

How to operate a sanitary ball valve?

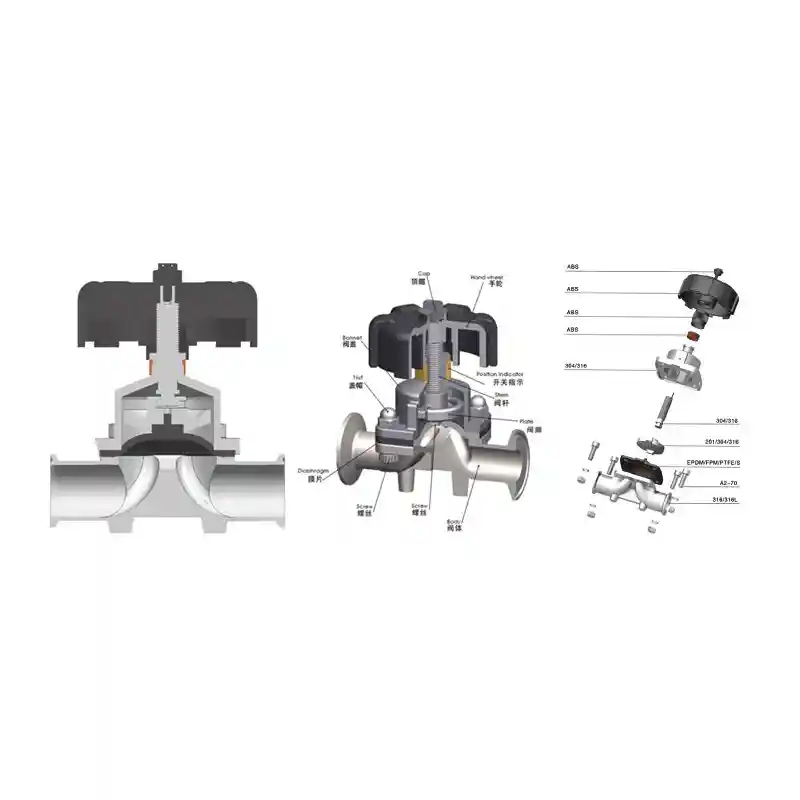

How to Correctly Use Stainless Steel Sanitary Diaphragm Valves?

How to Correctly Use Stainless Steel Sanitary Diaphragm Valves?

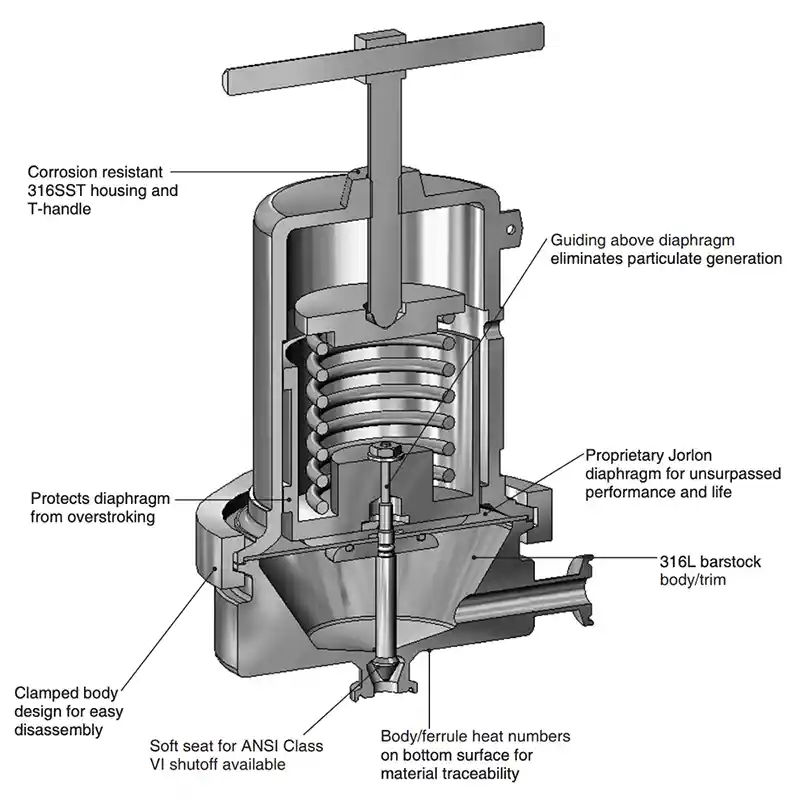

What is a Sanitary Pressure Regulator?

What is a Sanitary Pressure Regulator?

What Are Sanitary Valves?

What Are Sanitary Valves?