What are Forged Steel Valves?

Forged Steel Valves Product Overview: Classification, Features, Application & Maintenance

Forged Steel Valves - Product Overview, Classification, Features, Application & Maintenance

Forged steel valves are mainly applied in power, petrochemical and other industries for their characteristics of high compactness, high temperature and high pressure resistance. They are used for cutting off, connecting and regulating the pipeline medium, mainly for non-corrosive media such as water and steam, achieving reliable sealing and convenient operation. They are the upgraded replacement of cast steel valves.

Classification of Forged Steel Valves

By structure and function:

Gate Valve: For full opening or full closing to cut off the medium.

Globe Valve: For regulating and controlling flow rate.

Check Valve: Prevent medium backflow.

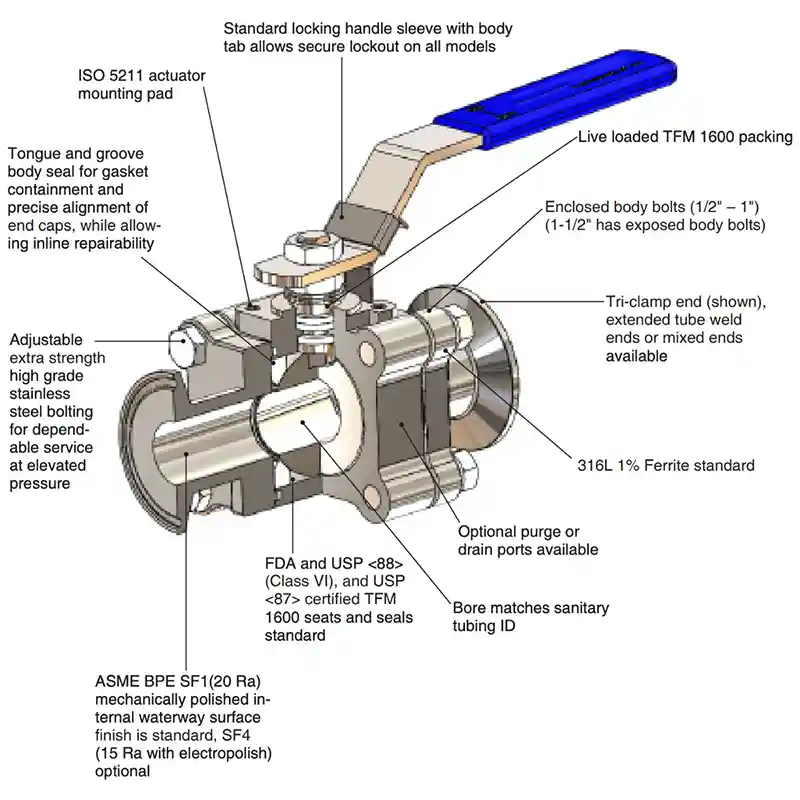

Ball Valve: Generally with low flow resistance, suitable for quick opening and closing.

Needle Valve: For precise flow regulation.

Bellows Valve: Adopt bellows seal for higher reliability.

By driving mode: Manual, Pneumatic, Electric.

By connection form: Common types include Flange Connection, Threaded Connection, etc.

Special types: Self-sealing Valve (reliable for high pressure), Insulated Valve, etc.

Features of Forged Steel Valves

High temperature & high pressure resistance: Adaptable to pipeline systems with high parameters.

High compactness: Integrally forged with uniform internal structure, free of air holes and sand holes, with low leakage risk.

Excellent sealing performance: Adopt self-sealing design, the higher the pressure, the more reliable the sealing effect.

Application Fields of Forged Steel Valves

Thermal power stations: Boiler water supply, steam and water circulation systems.

Petrochemical industry: Medium control for high temperature and high pressure pipelines.

Energy industry: Oil and gas transmission pipelines (lubrication shall be noted).

Others: Industrial pipelines for chemical engineering, metallurgy and other industries.

Maintenance Key Points

Grease injection: The grease injection volume and pressure shall be precisely controlled according to the valve type and size.

Lubrication: The valve stem part shall be kept lubricated to reduce operation resistance.

Working condition adaptation: For different media (such as the scouring property of gasoline), lubrication shall be supplemented in a timely manner.

How to operate a sanitary ball valve?

How to operate a sanitary ball valve?

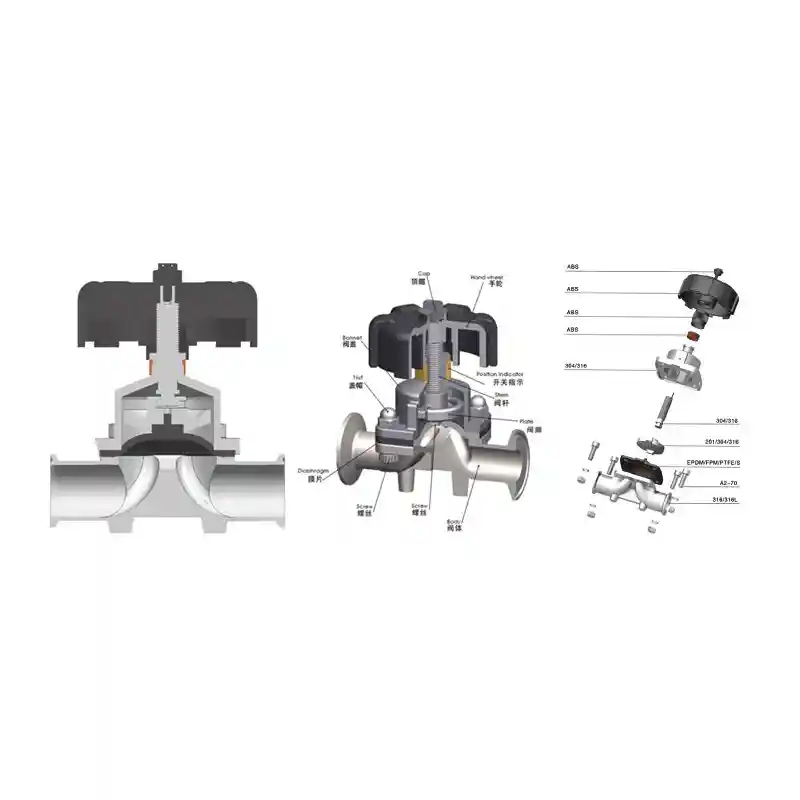

How to Correctly Use Stainless Steel Sanitary Diaphragm Valves?

How to Correctly Use Stainless Steel Sanitary Diaphragm Valves?

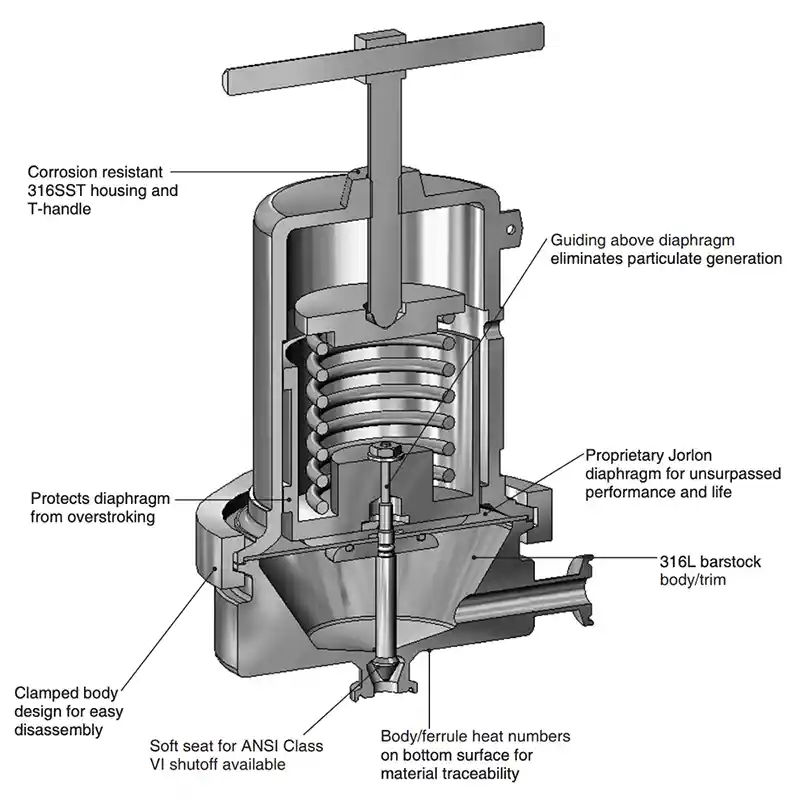

What is a Sanitary Pressure Regulator?

What is a Sanitary Pressure Regulator?

What Are Sanitary Valves?

What Are Sanitary Valves?