What is a Forged Steel Check Valve?

What is a Forged Steel Check Valve?

A forged steel check valve refers to a valve that automatically opens and closes the disc relying on the flow of the medium itself to prevent medium backflow, also known as a non-return valve, one-way valve, counterflow valve, and back pressure valve. As an automatic valve, its main functions are as follows:

Prevent medium backflow;

Prevent reverse rotation of pumps and drive motors;

Prevent leakage of medium in containers.

In addition, check valves can also be used on pipelines that supply make-up to auxiliary systems where the pressure may rise above the system pressure. They are mainly divided into swing check valves and lift check valves.

Working Principle

The core function of a forged steel check valve is to allow medium to flow in only one direction and prevent reverse flow. It works automatically, and the specific working process and structural characteristics are as follows:

Opening and closing mechanism: Under the pressure of fluid flowing in one direction, the disc opens; when the fluid flows reversely, the fluid pressure and the self-weight of the disc act on the valve seat to cut off the flow.

Common types: Including swing check valves and lift check valves (internal thread check valves and butterfly check valves belong to this category).

Swing check valve features: Equipped with a hinge mechanism and a door-like disc that rests freely on the inclined valve seat surface. The disc can be fully metal or inlaid with leather, rubber, or synthetic covering (depending on service performance requirements). When fully open, the fluid pressure is almost unobstructed, resulting in a relatively small pressure drop.

Lift check valve features: The disc seat is located on the valve seat sealing surface of the valve body. Except for the freely liftable disc, the rest structure is similar to that of a globe valve. Fluid pressure lifts the disc from the sealing surface, and medium backflow makes the disc fall back to cut off the flow.

Application Fields

Forged steel check valves are mainly used as anti-backflow devices in industrial pipelines. Key application characteristics and scenarios:

Structural application: Suitable for check valves where the disc rotates around the pin inside the valve seat.

Butterfly check valve application: With a simple structure, it can only be installed on horizontal pipelines and has good sealing performance, which is widely used in corresponding industrial pipeline systems.

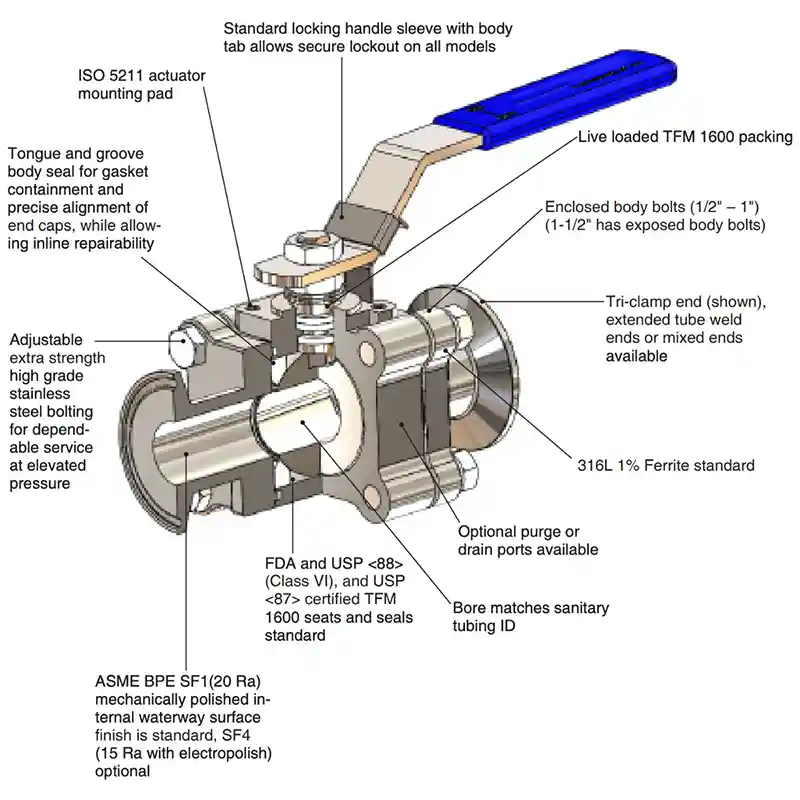

How to operate a sanitary ball valve?

How to operate a sanitary ball valve?

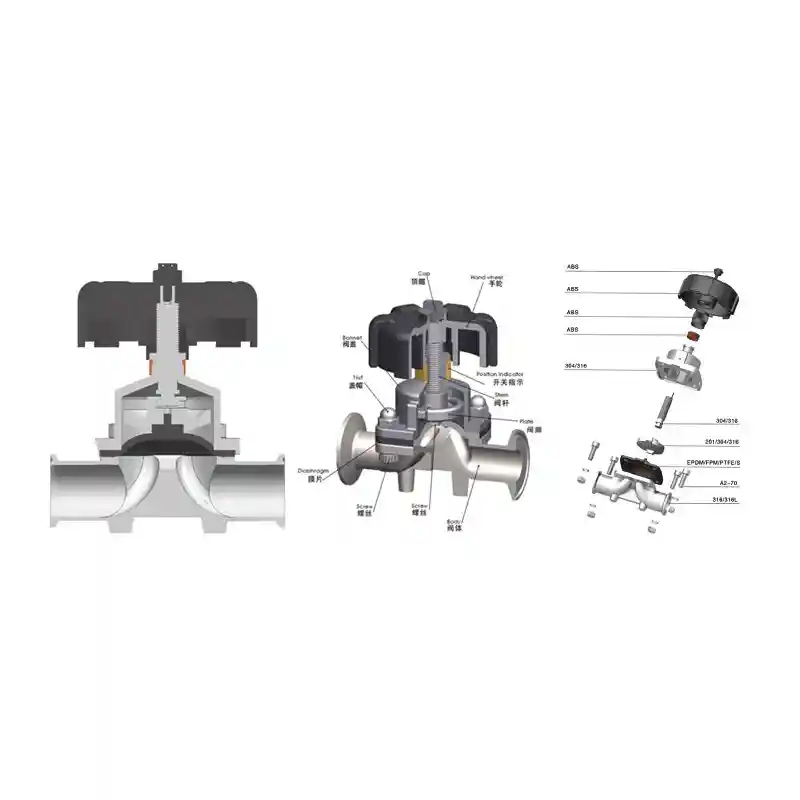

How to Correctly Use Stainless Steel Sanitary Diaphragm Valves?

How to Correctly Use Stainless Steel Sanitary Diaphragm Valves?

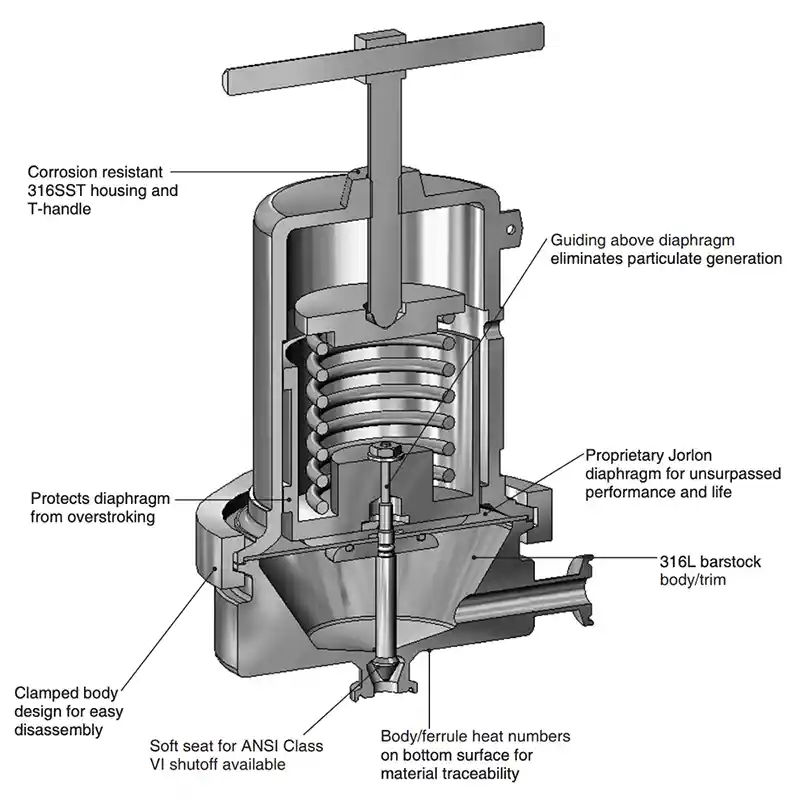

What is a Sanitary Pressure Regulator?

What is a Sanitary Pressure Regulator?

What Are Sanitary Valves?

What Are Sanitary Valves?