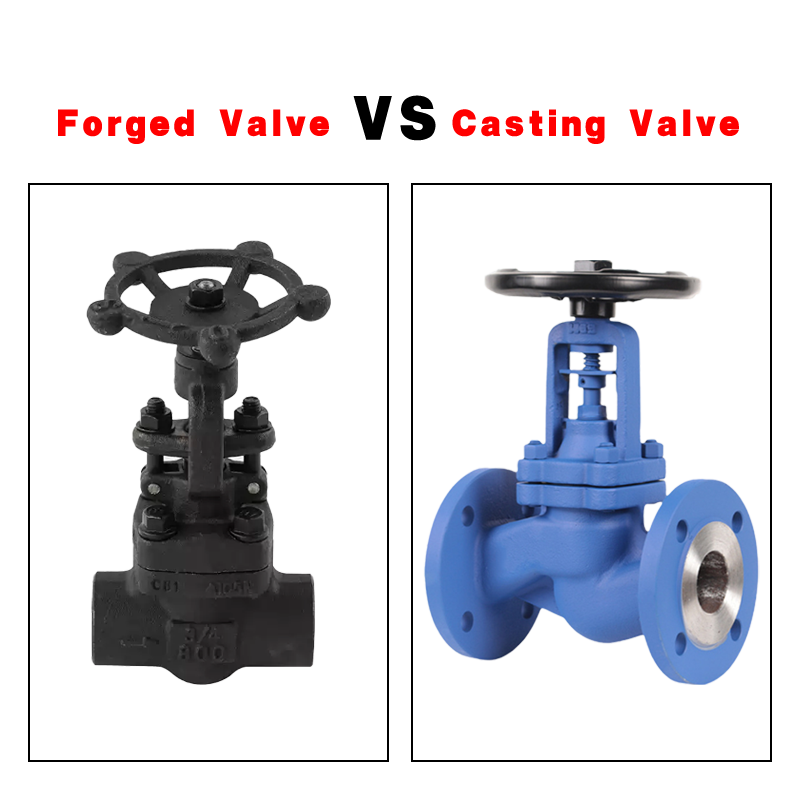

Forged Valves vs Cast Valves

Cast Valve

Cast valve refers to a technological process in which metal is smelted into a liquid that meets certain requirements, poured into a mold, and after cooling and solidification, as well as finishing treatment, a casting (part or blank) with predetermined shape, size and performance is obtained. It is a basic process in the modern machinery manufacturing industry. The blank cost of casting production is low, and it is more economical for parts with complex shapes, especially those with complex inner cavities; at the same time, it has a wide adaptability and good comprehensive mechanical properties.

Forged Valve

Forging is a processing method that shapes parts by means of hammering or extrusion after heating metal materials to a certain temperature. That is to say, it is a processing method that uses forging machinery to apply pressure to metal blanks to cause plastic deformation to obtain forgings with certain mechanical properties, certain shapes and sizes. Forging can eliminate cast looseness of metal and weld holes, and the mechanical properties of forgings are generally better than those of castings of the same material.

Differences Between Valve Casting and Forging

Different Processing Principles: Valve casting is the solidification and forming of liquid metal in a mold, while forging is processing and forming by means of hammering or extrusion after heating metal. Forging processing can change the grain structure of metal, thereby improving the strength and toughness of metal, while casting cannot change the grain structure of metal.

Different Processing Difficulty: The valve forging process is complex and difficult to process. It requires multiple complex links and precise operations to obtain valve parts with high precision and good quality. In contrast, the valve casting process is simple, easy to operate, and has lower requirements on equipment and technology.

Different Product Performance: Since valve forging can change the grain structure of metal, the density and performance of products are better. However, casting is prone to air holes and other defects, which have a certain impact on the performance and quality of products.

Different Complexity: Casting can produce complex patterns and shapes. Forging focuses more on producing uniform and simple materials.

Differences in Application Fields

Application of Forged Valves: For small valves, the forging process is usually adopted. For example, the valve stem is usually manufactured by forging, and rolled steel bars can be used instead. In low-pressure environments, rolled stems are also a feasible option. In addition, discs, valve bodies and bonnets can also be directly forged from bars. Forged valves usually have higher strength and durability.

Application of Cast Valves: For large-size valve components, casting is a more common choice. Casting can effectively manufacture large and complex valve structures. Cast materials include carbon steel (such as WCA, WCB, WCC), alloy steel (such as WC6, WC9), and stainless steel (such as CF8, CF8M, CF3, CF3M).

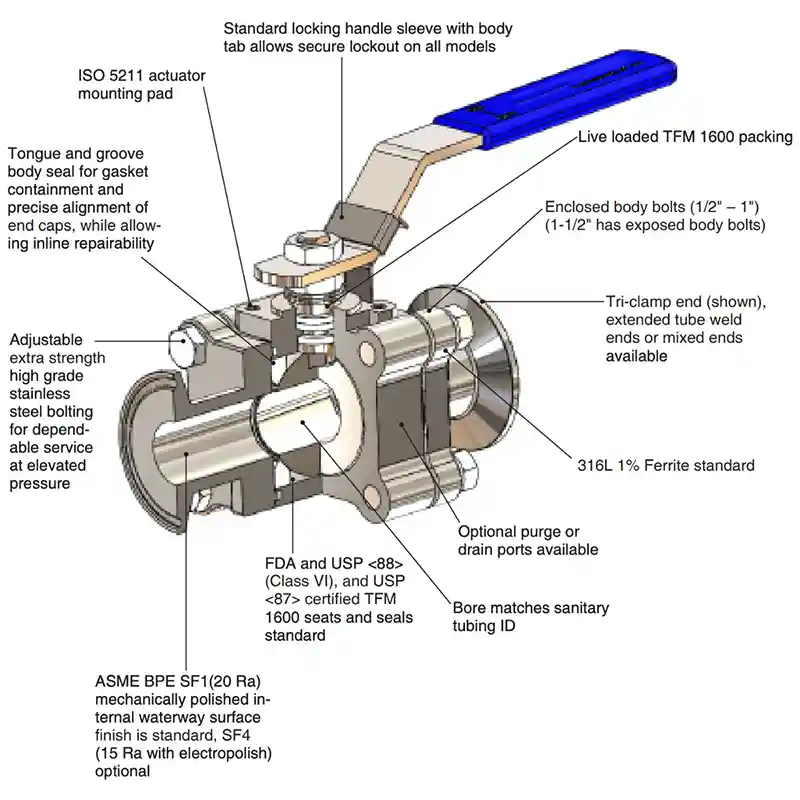

How to operate a sanitary ball valve?

How to operate a sanitary ball valve?

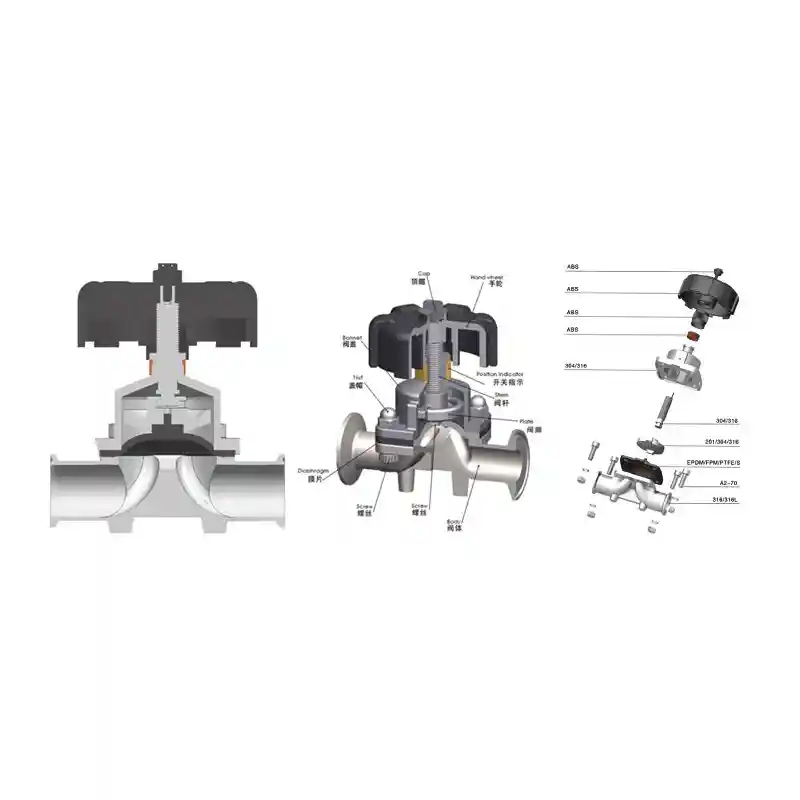

How to Correctly Use Stainless Steel Sanitary Diaphragm Valves?

How to Correctly Use Stainless Steel Sanitary Diaphragm Valves?

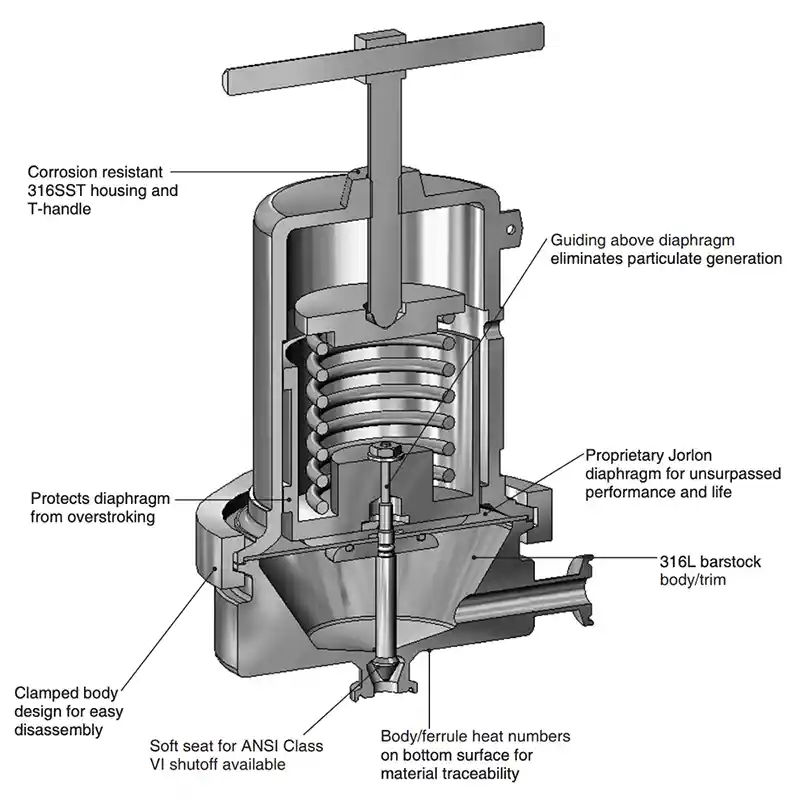

What is a Sanitary Pressure Regulator?

What is a Sanitary Pressure Regulator?

What Are Sanitary Valves?

What Are Sanitary Valves?