Installation and Operation Instructions for Y-Strainer

Installation and Operation Instructions for Y-Strainer

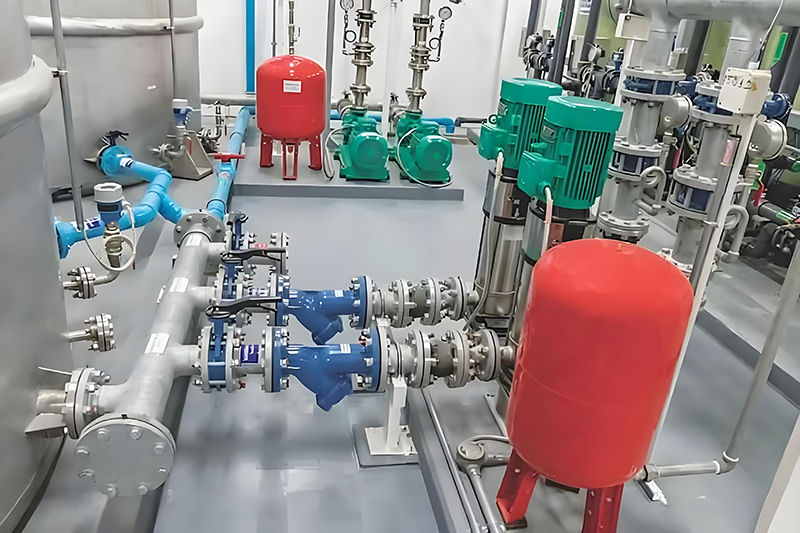

Y-Strainer is an indispensable device in pipelines for conveying media. Installed at the inlet end of pressure reducing valves, pressure relief valves, constant water level valves, or other equipment, it is a small-sized device used to remove a small amount of solid particles from liquids, protecting the normal operation of equipment. When fluid enters the filter cartridge equipped with a filter screen of a certain specification, impurities are blocked, while clean filtrate is discharged from the filter outlet. When cleaning is required, simply take out the removable filter cartridge, handle it, and reinstall it. Therefore, it is extremely convenient to use and maintain.

Features of Y-Strainer

Y-shaped, full, wide-valve body streamlined design with large filtration area and high flow rate.

Simple installation and maintenance, and easy filter screen cleaning.

Both internal and external surfaces are sprayed with environmental protection coating to ensure corrosion resistance and safety of the product.

Y-Strainer is mainly composed of connecting pipe, main pipe, filter screen, flange, flange cover, and fasteners. When liquid enters the filter basket through the main pipe, solid impurity particles are blocked in the filter basket, and clean fluid is discharged from the filter outlet through the filter basket.

Installation Steps of Y-Strainer

Before installation, must open the product's plastic packaging within a cleanroom environment;

When carrying, hold the filter's outer frame with both hands;

Installing large filters requires at least two people;

Do not hold the middle part of the filter;

Do not touch the internal materials of the filter;

Do not use tools to cut open the filter's outer packaging;

Be careful not to deform the filter element during transportation;

Protect the filter's gasket to avoid collision with other objects.

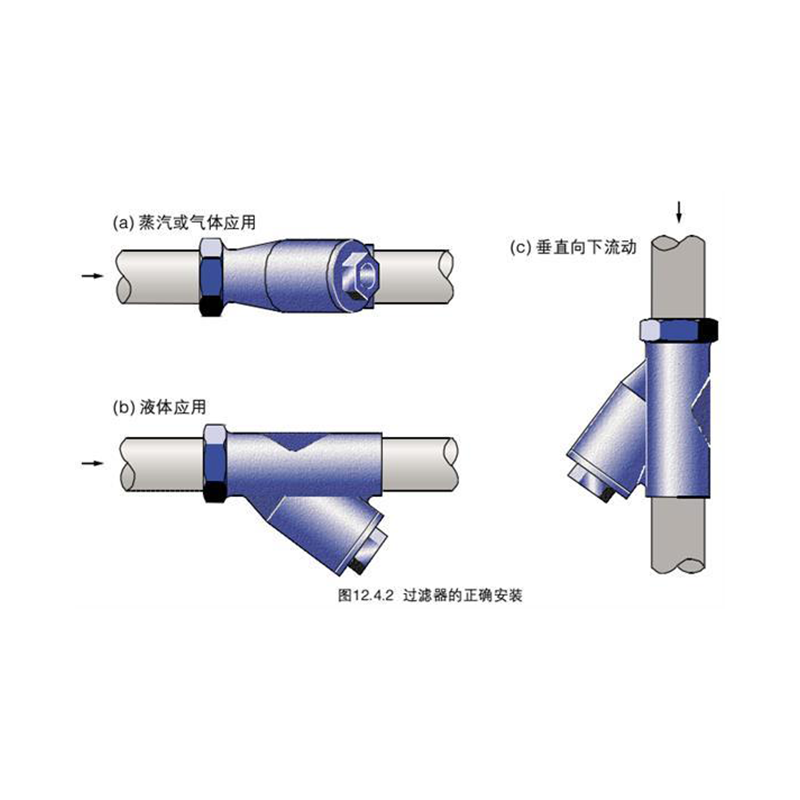

Installation Direction of Y-Strainer

Steam or gas pipelines: Filter screen facing horizontally;

Liquid pipelines: Filter screen facing downward;

Vertical installation: Follow the filter's installation indication.

Installation Notes of Y-Strainer

The installation of Y-Strainer shall be carried out in accordance with the flow direction, recommended installation method, and installation requirements shown in the product catalog and installation instructions provided by the manufacturer.

A differential pressure gauge or pressure gauge can be installed upstream and downstream of the Y-Strainer according to the needs of process production to judge the clogging status, and a backblow cleaning pipeline shall be configured according to process requirements.

The pipeline piping shall consider the convenience of installation and removal of the Y-Strainer.

Pipeline design requirements for pipeline filters.

Pipelines equipped with Y-Strainers can be divided into intermittent operation and continuous operation during work.

For intermittent operation: Install isolation valves before and after the Y-Strainer to facilitate filter cleaning.

For continuous operation: Equip two parallel sets of filters for the system, and install isolation valves before and after each filter (except for wire-wound filters).

Operation and Maintenance of Y-Strainer

After the system has been working for a period of time (generally no more than one week), cleaning should be performed to remove impurities accumulated on the filter screen during the initial operation of the system.

Subsequently, regular cleaning is required. The frequency of cleaning depends on the working conditions. If the filter is not equipped with a blowdown plug,

the filter screen stopper and filter screen must be removed when cleaning the filter.

Note: Before each maintenance and cleaning, isolate the filter from the pressurized system. When reinstalling after cleaning, use a new gasket.

The above is the detailed description of the installation and maintenance of Y-Strainer. In addition, it is necessary to choose a suitable environment during installation so that the Y-Strainer can better play its role and ensure the cleanliness of the medium in the system.

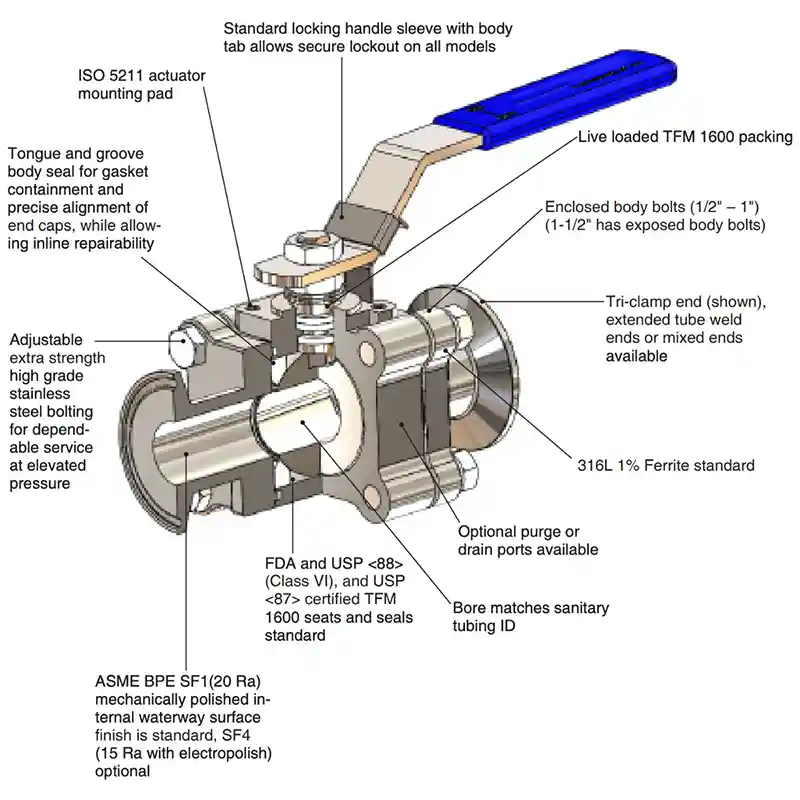

How to operate a sanitary ball valve?

How to operate a sanitary ball valve?

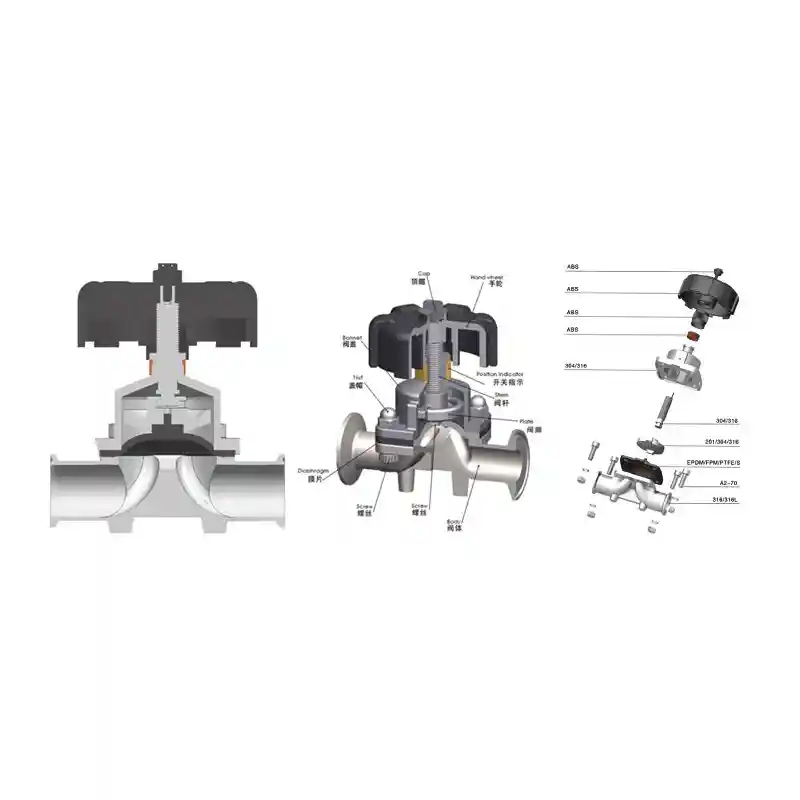

How to Correctly Use Stainless Steel Sanitary Diaphragm Valves?

How to Correctly Use Stainless Steel Sanitary Diaphragm Valves?

What is a Sanitary Pressure Regulator?

What is a Sanitary Pressure Regulator?

What Are Sanitary Valves?

What Are Sanitary Valves?