What is a Check Valve and How does it works?

A check valve is a type of valve that allows fluid to flow in a fixed direction and automatically prevents its reverse flow (backflow), also known as a non-return valve. It is an automatically closing valve with a valve disc or swing plate inside the valve body. When the medium flows forward, the fluid automatically lifts the valve disc; when the fluid flows backward, the fluid (or spring force) automatically closes the valve disc.

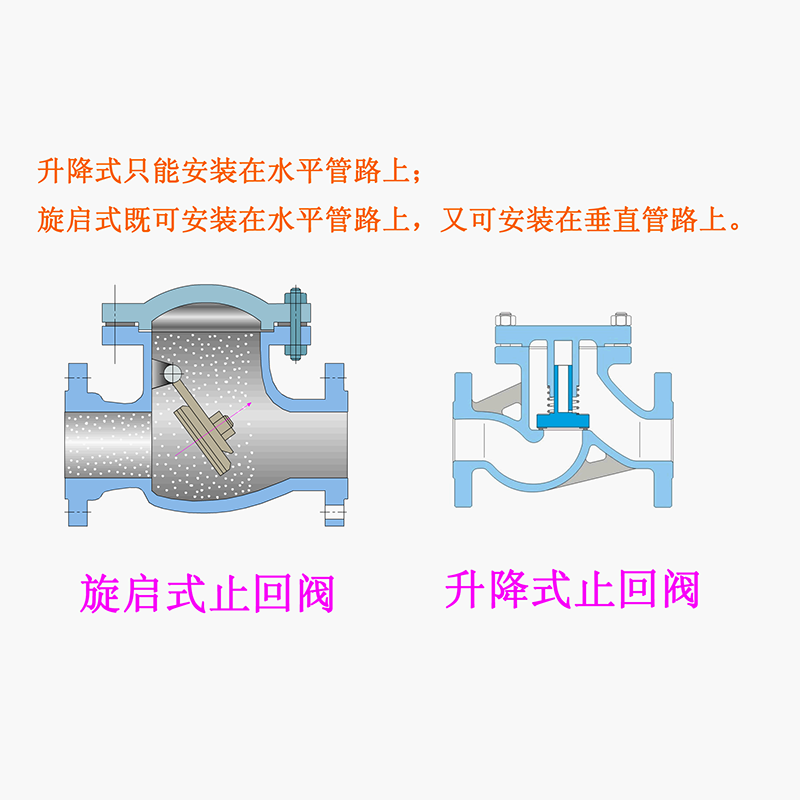

The disc of a lift check valve moves up and down perpendicular to the valve body channel, and it is generally used on horizontal or vertical pipelines; the disc of a swing check valve is often called a swing plate, which is connected to a shaft on one side and can rotate around the shaft. Swing check valves are generally installed on horizontal pipelines, and small-caliber ones can also be installed on vertical pipelines, but attention should be paid to the flow rate not being too large.

Check valves are generally suitable for pipelines with clean media and should not be used for pipelines with solid particles and high-viscosity media. The sealing performance of lift check valves is better than that of swing check valves, but the fluid resistance of swing check valves is smaller than that of lift check valves. In general, swing check valves are suitable for large-caliber pipelines.

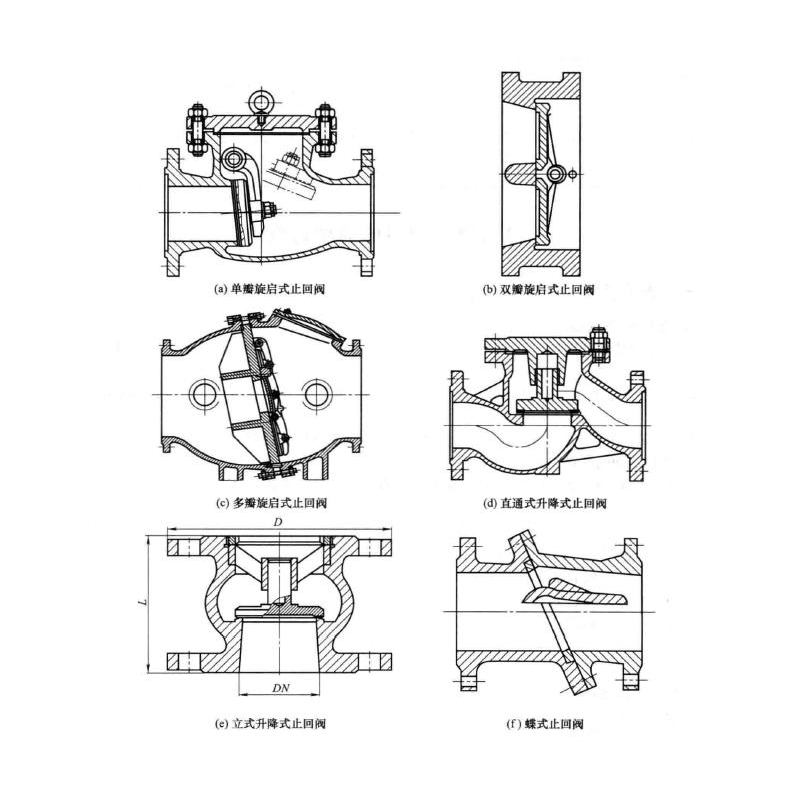

According to the different structures of check valves, they are divided into lift check valves, swing check valves, axial flow check valves, butterfly check valves and other special check valves.

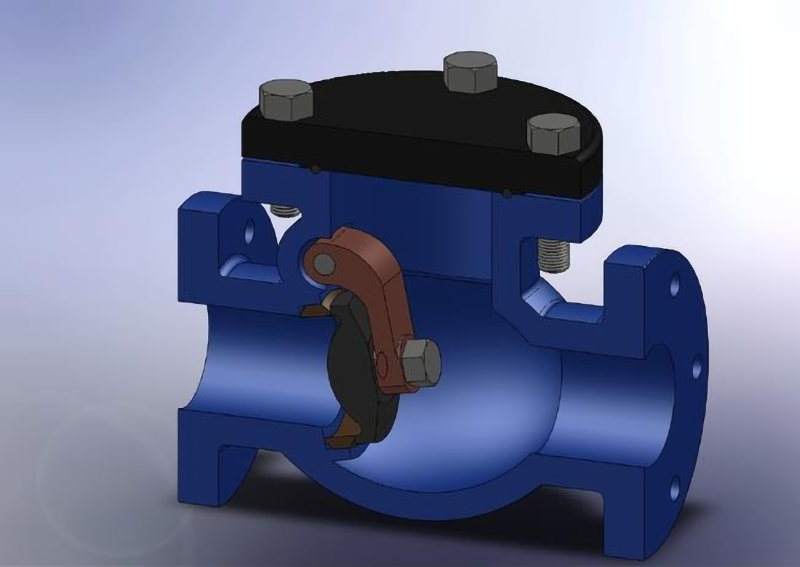

1. Swing Check Valve

The disc of a swing check valve is disc-shaped and rotates around the rotating shaft of the valve seat channel. Due to the streamlined channel inside the valve, the flow resistance is smaller than that of a lift check valve. It is suitable for large-caliber occasions with low flow rate and infrequently changing flow, but it should not be used for pulsating flow, and its sealing performance is not as good as that of a lift check valve. Swing check valves are divided into three types: single-disc, double-disc and multi-disc. These three types are mainly divided according to the valve caliber, aiming to reduce hydraulic impact when the medium stops flowing or flows backward.

2. Lift Check Valve

A lift check valve is a check valve whose disc slides along the vertical center line of the valve body. For high-pressure and small-caliber check valves, the disc can be a ball. The shape of the valve body of a lift check valve is the same as that of a globe valve (can be used universally with a globe valve), so its fluid resistance coefficient is relatively large. Its structure is similar to that of a globe valve, and the valve body and disc are the same as those of a globe valve. A guide sleeve is processed on the upper part of the disc and the lower part of the valve cover, and the disc guide sleeve can freely lift in the valve cover guide sleeve. When the medium flows forward, the disc opens by the medium thrust; when the medium stops flowing, the disc falls on the valve seat by its own weight to prevent medium backflow.

3. Axial Flow Check Valve

With the construction and expansion of large domestic petrochemical projects such as oil refining and ethylene, pipeline systems with harsh working conditions such as compressors and large pumps in long-distance oil and gas pipeline systems and large ethylene plants require check valves with fast closing, low pressure loss and low noise. Especially for gas phase media, for ordinary swing and double-plate check valves, the valve plates often cannot be fully opened, resulting in unstable medium flow, large pressure loss, easy mechanical vibration, high noise, etc., thus affecting the normal operation of large compressors and pumps. At this time, it is necessary to use a special type of axial flow check valve to ensure the safe and effective operation of the above equipment and pipeline systems.

4. Butterfly Check Valve

The installation position of the butterfly check valve is not limited; it can be installed on horizontal pipelines, as well as vertical or inclined pipelines.

Low-resistance slow-closing butterfly check valve: It is mainly composed of a valve body, two semicircular valve discs, a return spring, an oil storage cylinder, a slow-closing small cylinder group, and a needle valve (micro-regulating valve). It can be used on drainage pipelines for media such as clean water, sewage, and seawater. It can not only prevent medium backflow but also effectively limit destructive water hammer, ensuring the safe use of the pipeline. It is not suitable for media containing solid particles and high-viscosity particles. It has a small size, light weight, and a structural length of about one-third of that of a swing check valve.

This article will focus on the check valve installed on the outlet side of the steam trap.

Spring Disc Check Valve

The opening and closing pressure difference of the spring disc structure valve is very small, and the sealing is tight. Once back pressure occurs, the valve closes immediately.

The center-guided design prevents large-caliber check valves from sticking and jamming due to disc inclination, ensuring reliable operation.

Is it necessary to install a check valve on the outlet side of the steam trap?

If there is a possibility of condensate backflow, it is necessary to install a check valve. For example, when condensate is discharged to a common collection pipeline, condensate discharged from other traps may flow back to the equipment. Therefore, a check valve must be installed under such working conditions. Preventing such backflow is very important because it will not only affect heating efficiency but also is likely to damage the trap. On the contrary, if the outlet of the trap is connected to a separate drain pipe for downward discharge, backflow will not occur, and there is no need to install a check valve.

If the trap discharges downward to the atmosphere through a separate drain pipe, there is usually no risk of backflow, so it is not necessary to install a check valve.

Note: Based on the pipeline configuration after the trap, if the equipment is in a vacuum condition or there is a pipeline lift, the back pressure may exceed the primary pressure, resulting in backflow. In this case, installing a check valve can effectively prevent backflow.

If the outlet of the trap is recovered to the same condensate collection pipeline, without a check valve, the condensate discharged from the operating equipment may flow back to other out-of-service equipment.

If a check valve is installed, even if the outlet of the trap is connected to the same collection pipeline, the condensate discharged from the operating equipment will not flow back to other out-of-service equipment.

Can a check valve prevent water hammer?

There are many factors that cause water hammer. The biggest cause of water hammer in condensate recovery pipelines is the backflow of condensate from the lift pipe. Installing a check valve in these places is of great help in preventing water hammer caused by backflow.

One of the causes of water hammer is the backflow caused by the lift pipe in the recovery pipeline.

If the discharge of condensate is controlled by an intermittently operating pump (such as the TLV PowerTrap® series or a power pump with on-off control), and there is a horizontal pipeline before the lift pipe, the condensed water flowing back from the lift pipe may collide with the newly discharged condensed water, resulting in water hammer. Similarly, when PowerTrap® discharges high-temperature condensate, the generated flash steam colliding with backflow and condensed water is another possible cause of water hammer.

Under such working conditions, installing a check valve at an appropriate position in the system (such as the starting position of the lift pipe) is of great help in preventing water hammer.

In condensate transmission pipelines, water hammer caused by the pulsed flow of low-temperature condensate can also be helped by using check valves.

Usage Limitations of Check Valve

When high-temperature and high-pressure condensate is discharged through the trap to a lower pressure area, a certain amount of flash steam will be generated. If this flash steam flows into the recovery pipeline filled with low-temperature condensate, the flash steam will transfer its latent heat to the condensate, resulting in rapid condensation and water hammer. Under such working conditions, installing a check valve will not work.

A check valve can prevent backflow but cannot reduce back pressure. It cannot allow condensate to be discharged from a low-pressure area to a high-pressure pipeline. Even if a globe valve is installed after the trap, if the primary pressure is less than the secondary pressure, the condensate cannot be discharged.

In addition, it should be noted that if a check valve is installed after a trap with a very small pressure difference, the check valve itself will also become a resistance point (that is, the check valve also has pressure loss). Therefore, special attention should be paid when calculating the pressure drop.

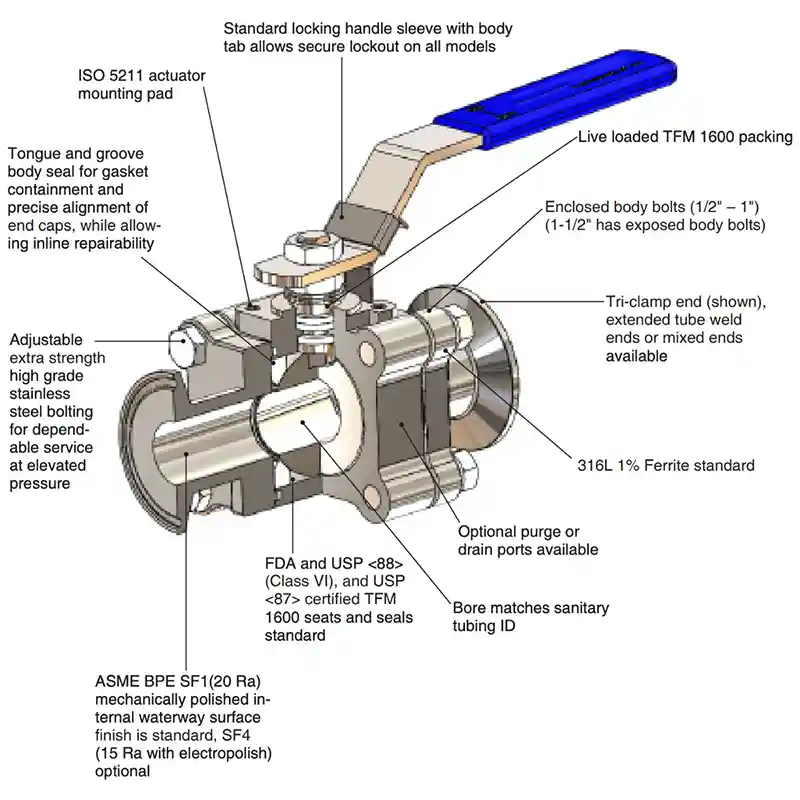

Structure of Sanitary Ball Valves with Clamp Ends

Structure of Sanitary Ball Valves with Clamp Ends

How to operate a sanitary ball valve?

How to operate a sanitary ball valve?

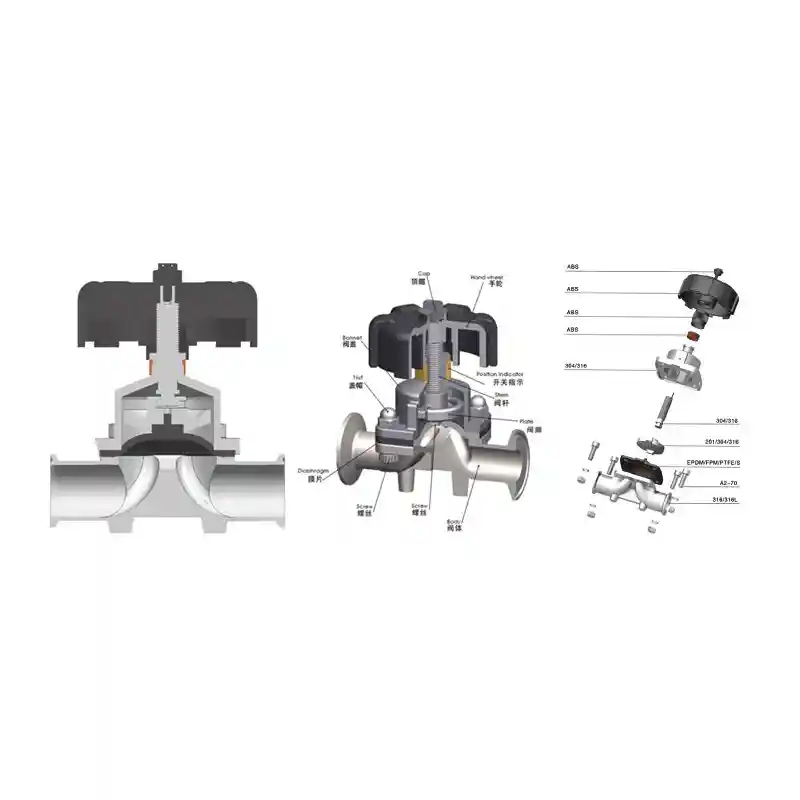

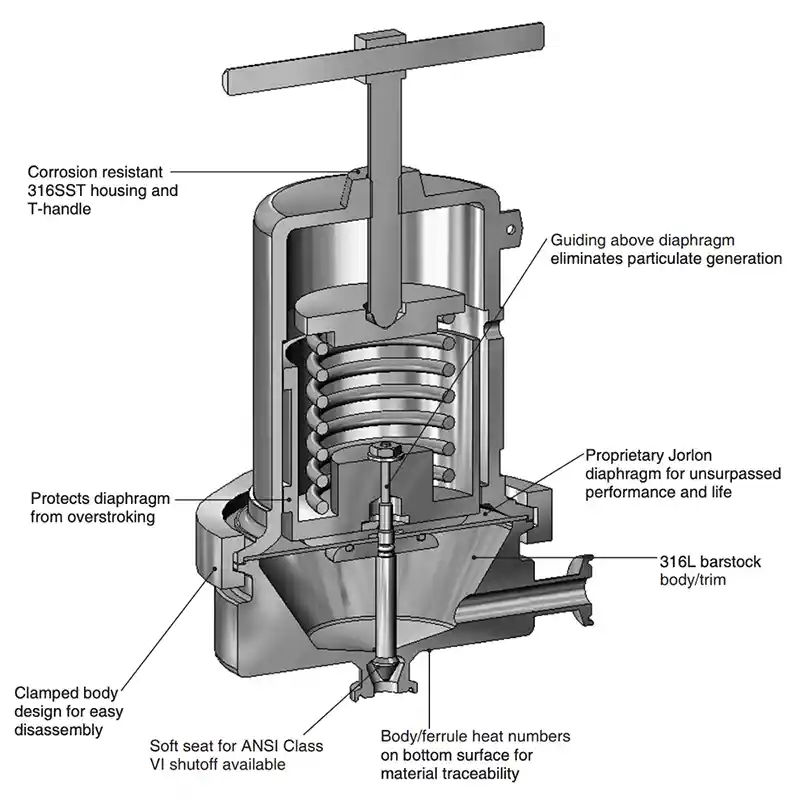

How to Correctly Use Stainless Steel Sanitary Diaphragm Valves?

How to Correctly Use Stainless Steel Sanitary Diaphragm Valves?

What is a Sanitary Pressure Regulator?

What is a Sanitary Pressure Regulator?