What is a Bellows Sealed Valve?

What is a Bellows Sealed Valve?

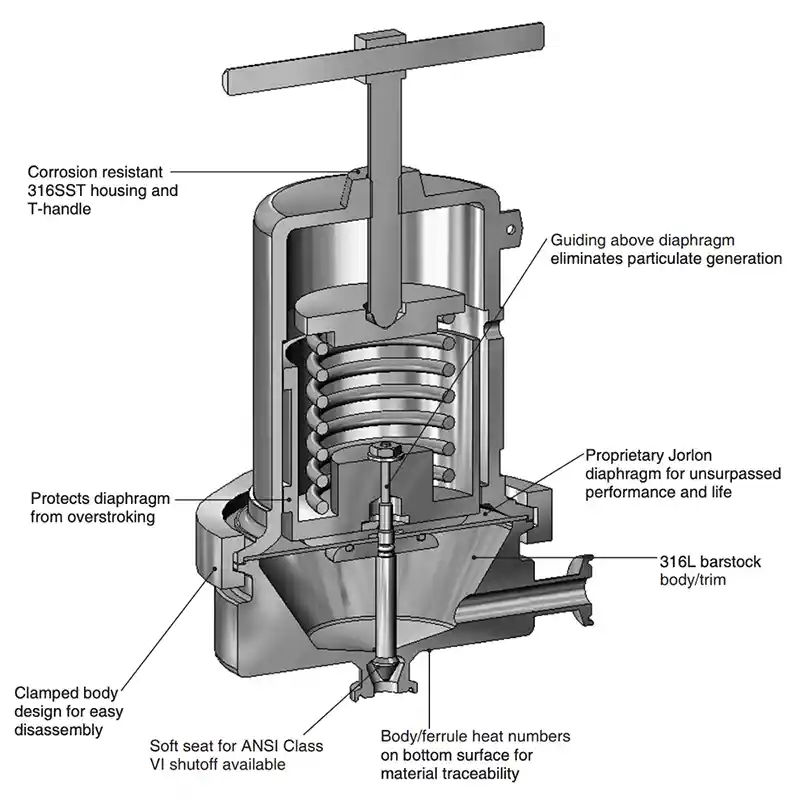

Bellows sealed valves are applicable to equipment and pipelines conveying media such as air, steam and petroleum gas with an operating temperature ≤300℃, serving as overpressure protection devices. When the pressure inside the equipment and pipelines exceeds the allowable value, the valve opens automatically and then discharges the medium in full capacity; when the pressure drops to the specified value, the valve closes automatically to ensure the safe operation of the equipment. It is widely used in electric power, metallurgy, petroleum, chemical industry and other industries. However, bellows sealed safety valves are not suitable for reciprocating compressors. Due to the excessive pressure fluctuation of process fluid before and after the compressor, the bellows is sensitive to such fatigue stress, which will greatly reduce the service life of the valve.

Bellows sealed valves also have the following characteristics:

The valve seat and valve body are detachable, featuring convenient maintenance and cost-effectiveness. The umbrella-shaped recoil disc can effectively increase the lift force, enabling the valve disc to open rapidly and discharge the medium under relatively low pressure, so as to achieve the purpose of protecting the equipment. The adjusting ring can adjust the satisfactory opening and closing pressure difference. Rational selection of materials for the recoil disc, guide sleeve, valve stem and adjusting screw, as well as proper selection of clearances, ensure the flexible movement of the valve disc. The sealing surfaces of the valve disc and valve seat are overlay welded with hard alloy, and high sealing performance and long service life are guaranteed after fine surface grinding.

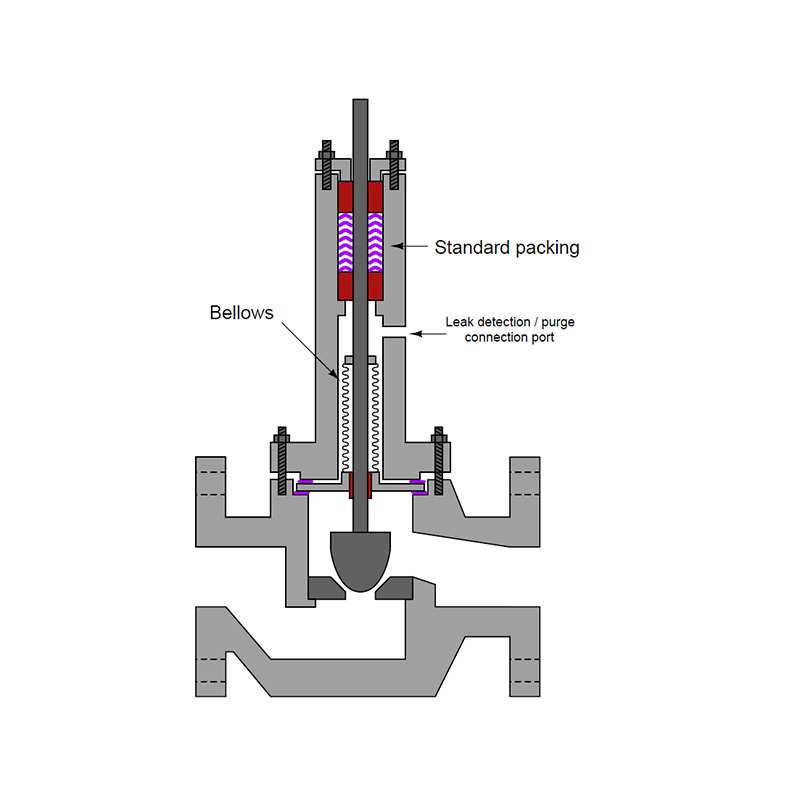

The bellows in the bellows sealed valve can eliminate the influence of back pressure fluctuation on valve performance, and also protect the spring and other internal parts from corrosion by the medium. The material selection and processing of the spring and bellows are exquisite, and all bellows sealed valves are subject to rigorous testing and inspection.

Application of Bellows in Valves

Bellows Overview, Types of Bellows, Application of Bellows in Valves, Bellows Materials

Bellows Overview

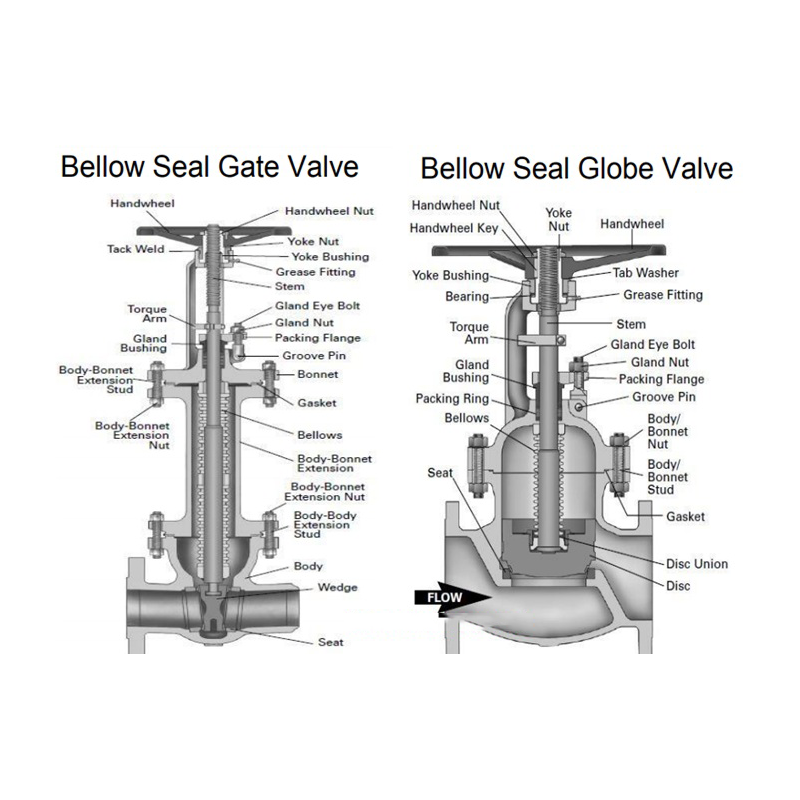

Bellows is one of the important basic mechanical components, and is also widely used in valves. Bellows are installed as key sealing or sensitive components in parts of various valves including globe valves, gate valves, safety valves, steam traps and pressure reducing valves.

Application of Bellows in Valves

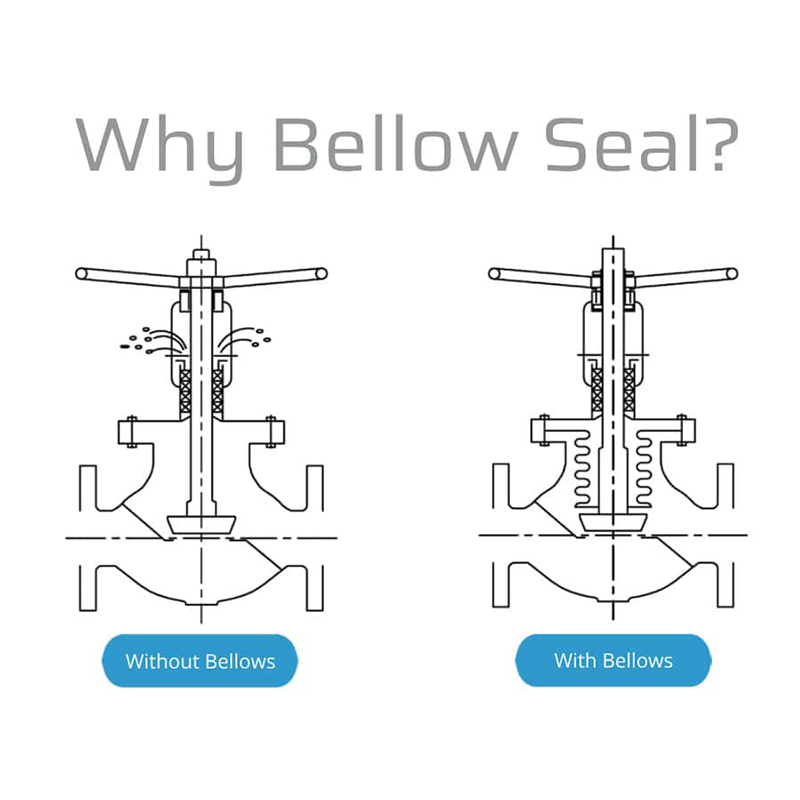

In gate valves, globe valves and safety valves, the main function of bellows is to enhance the sealing performance and improve the sealing capacity, which is an important part of the packing. The high-efficiency sealing performance of bellows allows these valves to be used in occasions with high sealing requirements, such as toxic and polluted working conditions.

In steam traps and pressure reducing valves, bellows are used as sensitive components, which can improve the action sensitivity of valves and expand the application range of valves.

Types of Bellows

In the application of bellows in various valves, the type shall be selected according to the application and technical requirements. According to the layer structure, bellows can be divided into single-layer, double-layer and multi-layer bellows. According to the processing method, it can be divided into integral bellows and welded bellows; according to the external shape, it can be divided into annular bellows and spiral bellows. According to the combination sequence, it can be divided into single-unit bellows and series bellows. Each type of bellows has its own advantages and disadvantages and respective application fields, and the selection shall be made in combination with actual conditions.

Bellows Materials

The selection of bellows materials for valve applications shall also be taken into consideration. Materials such as copper alloy, stainless steel and plastic are available, which are installed at the connection part of the valve stem.

Design Considerations for Bellows Sealed Valve

Deformation of bellows in opening and closing states

Bellows are in tension and compression states respectively during the opening and closing process of the valve. This deformation is a key factor in bellows design, which shall ensure good performance and durability under both states.

Torque bearing capacity

An important point in bellows design is that they cannot bear large torque. Therefore, the design shall ensure that the bellows only undergo tension and compression during operation to avoid any torsional force that may cause damage.

Material compatibility

The selection of suitable bellows materials is crucial. Practice has proved that nickel-based alloy is an excellent material choice, especially in applications that need to withstand high temperature and high pressure.

Welding quality

The welding quality of bellows is crucial to the performance of the entire valve. Process qualification shall be carried out and detailed welding records shall be established to ensure the quality and reliability of the welding process.

Consideration for throttling application

When bellows sealed valves are used as throttling devices, the influence of flow velocity on bellows must be taken into account. Improper flow velocity may cause damage to the bellows, thus affecting the overall performance of the valve.

Minimum laminate thickness and pressure test

Bellows shall have the minimum laminate thickness required to withstand the expected pressure, and corresponding tests shall be carried out to ensure their performance.

Clearance between bellows and valve stem

The clearance between bellows and valve stem shall generally be maintained between 1 and 2 mm. This clearance is an important parameter to ensure the normal operation of the valve.

Stiffness and operating torque

In the design of bellows, its inherent stiffness and how this stiffness affects the torque required for operation shall be taken into consideration. The tension or compression of bellows may lead to an increase in operating torque, which needs to be considered in the design stage.

The design of metal bellows sealed valves is a complex process requiring careful consideration. Every aspect, from material selection to structural design, needs precise calculation and consideration to ensure the performance and safety of the valve in practical application. By focusing on these key factors, reliable and efficient bellows sealed valves can be designed to meet stringent industrial standards.

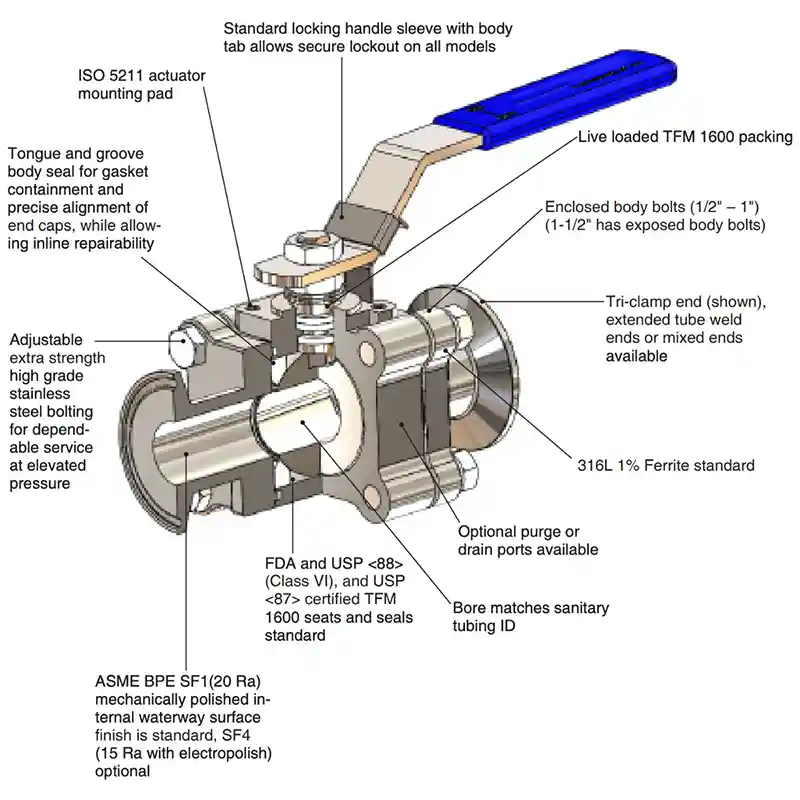

How to operate a sanitary ball valve?

How to operate a sanitary ball valve?

How to Correctly Use Stainless Steel Sanitary Diaphragm Valves?

How to Correctly Use Stainless Steel Sanitary Diaphragm Valves?

What is a Sanitary Pressure Regulator?

What is a Sanitary Pressure Regulator?

What Are Sanitary Valves?

What Are Sanitary Valves?