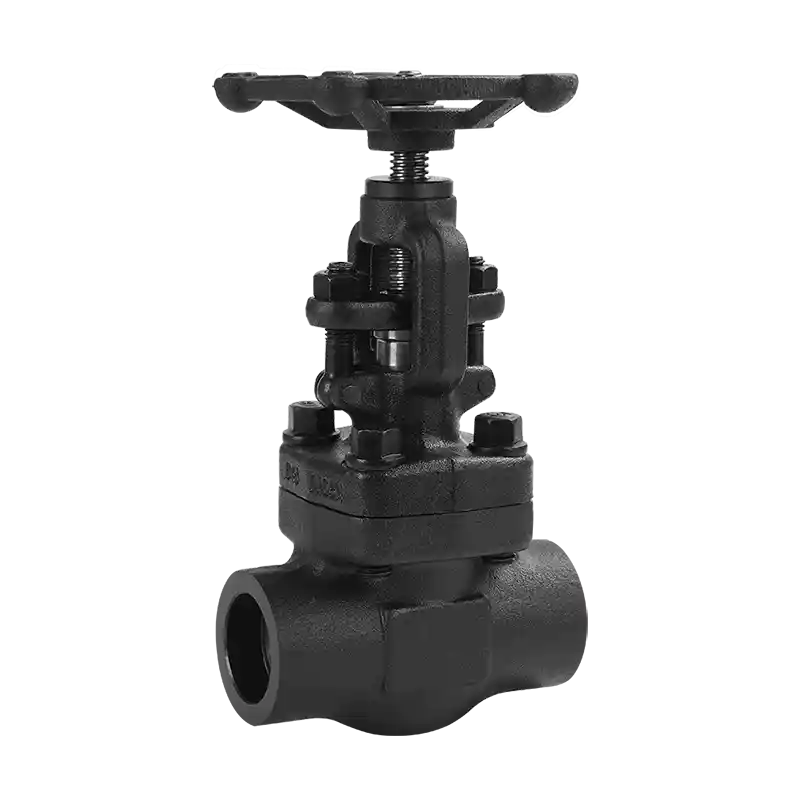

Flanged Forged Steel Check Valve

Flanged Forged Steel Check Valve - Product Description, Features, Specifications & Scope

The sealing surfaces of the disc and seat of the flanged forged steel check valve are formed by plasma spray welding of cobalt-based cemented carbide, featuring high hardness, erosion resistance and durability. It is suitable for pipelines in various working conditions such as petroleum, chemical, hydropower and thermal power stations with a nominal pressure of PN1.6~42.0Mpa and an operating temperature of 600℃ to cut off or connect media. Applicable media: water, oil products, steam, gases, certain corrosive liquids, etc.

Main Features

Cemented carbide is surfacing-welded on the guide ribs, and the guide sleeve in the upper cavity of the valve body is made of stainless steel to ensure flexible movement of the disc;

The sealing surfaces of the disc and seat are formed by plasma spray welding of cobalt-based cemented carbide, featuring high hardness, erosion resistance and durability;

Advanced pressure seal design and high-purity graphite gasket ring to ensure high air tightness;

The valve cavity adopts a pressure self-tightening seal structure, and the higher the internal cavity pressure, the better the sealing performance;

The disc rotates around the pin outside the seat, reducing the violent impact during closing.

Product Specifications

Design Specification: API 602

Structural Length: ANSI B16.10

Connection Standard: ANSI B16.5

Pressure Test: API 598

Product Scope

Main Material: Forged Steel

Nominal Diameter: 3/8″-2″

Pressure Range: 150LB-2500LB

Applicable Temperature: ≤425 ℃

Applicable Media: Water, Petroleum, Natural Gas, etc.