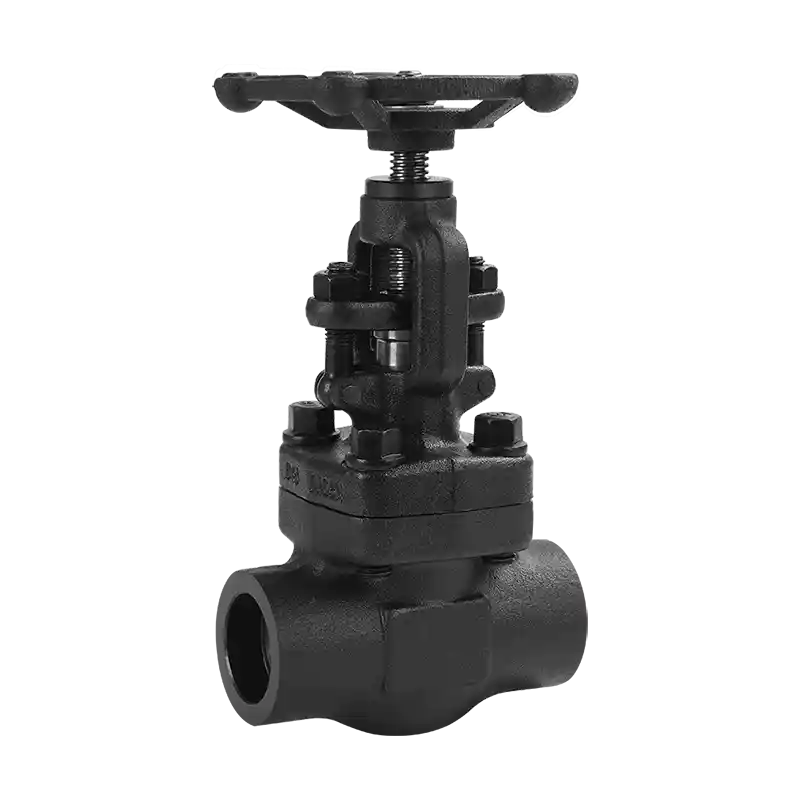

Internal Thread Forged Steel Check Valve

Internal Thread Forged Steel Check Valve - Application, Structural Features, Standards & Performance Parameters

The internal thread forged steel check valve is suitable for small-diameter pipelines with an operating temperature of -29~425℃ (carbon steel) or -29~500℃ (stainless steel). It is used to cut off or connect the medium in the pipeline. By selecting different materials, it can be applied to various media such as water, steam, oil products, nitric acid, acetic acid, oxidizing media, and urea.

Structural Features

Full port or reduced port;

Lift check valve;

Ball check valve;

Swing check valve;

Built-in spring as required;

Bolted bonnet with spiral wound gasket seal, threaded bonnet with full-weld seal, and threaded bonnet;

Threaded internal pressure self-tightening bonnet;

Integral upper sealing seat;

Socket end conforming to ASME B16.11;

Threaded end (NPT) conforming to ANSI/ASME B1.20.1;

The disc can be converted into throttling type, needle type, and ball type.

Executive Standards

Design Specification: ASME/ANSI B16.34, API 602, JB/T 7746

Connection End Dimensions: ASME/ANSI B16.11, JB/T 1751; ASME/ANSI B1.20.1, GB/T 7306

Connecting Flange: GB/T 9113, JB/T 79, HB/T 20592

Test and Inspection: API 598, GB/T 13927

Pressure-Temperature: GB/T 12224

Performance Parameters

Nominal Diameter: DN15~50mm; NPS1/2" ~2"

Nominal Pressure: PN16~25MPa; Class900~1500Lb

Applicable Media: Water, steam, oil products, nitric acid series

Applicable Temperature: -29~550℃

Main Materials: A105, 1Cr18Ni9Ti