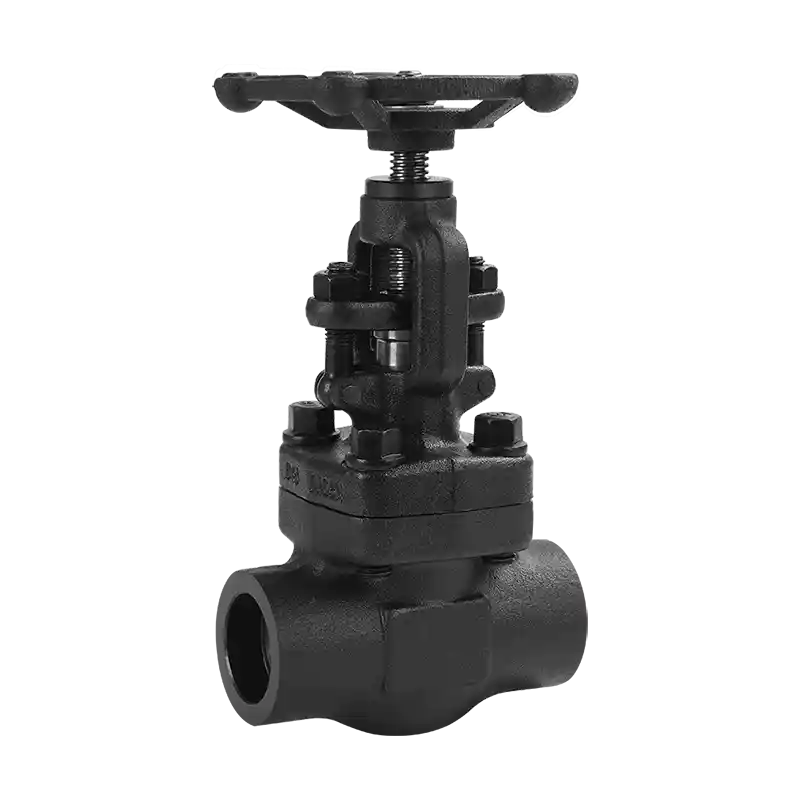

High Temperature and High Pressure Gate Valve

High Temperature and High Pressure Gate Valve - Application, Parameters & Structural Features

Welded structure, adapting to different nozzle requirements. The sealing surfaces of the gate plate and valve seat are surfacing-welded with Stellite cobalt-based cemented carbide, featuring wear resistance, high temperature resistance, corrosion resistance and good scratch resistance. The valve stem is quenched and tempered and surface nitrided, with good corrosion resistance and scratch resistance. The structure of the opening and closing parts can be designed into different forms such as single plate, double plate and parallel double plate according to user requirements. The high temperature and high pressure gate valve is suitable for pipelines of various working conditions such as petroleum, chemical industry and thermal power stations with a nominal pressure of 16.0-32.0Mpa and an operating temperature of ≤540℃ to cut off or connect media. Applicable media: water, oil products, steam, acidic media, etc. Operation methods include: manual, gear transmission, electric, etc.

Parameters of High Temperature and High Pressure Gate Valve

Connection Form: Welding

Main Material: Alloy Steel

Nominal Diameter: DN25-300mm

Applicable Media: Water, Steam, Oil Products, etc.

Material: Alloy Steel

Pressure Environment: High Pressure

Operating Temperature: High Temperature

Structural Features of High Temperature and High Pressure Gate Valve

Small fluid resistance, and the sealing surface is less scoured and eroded by the medium;

Relatively labor-saving to open and close;

The medium flow direction is not restricted, no turbulence, and no pressure reduction;

Simple shape, short structural length, good manufacturability and wide application range.