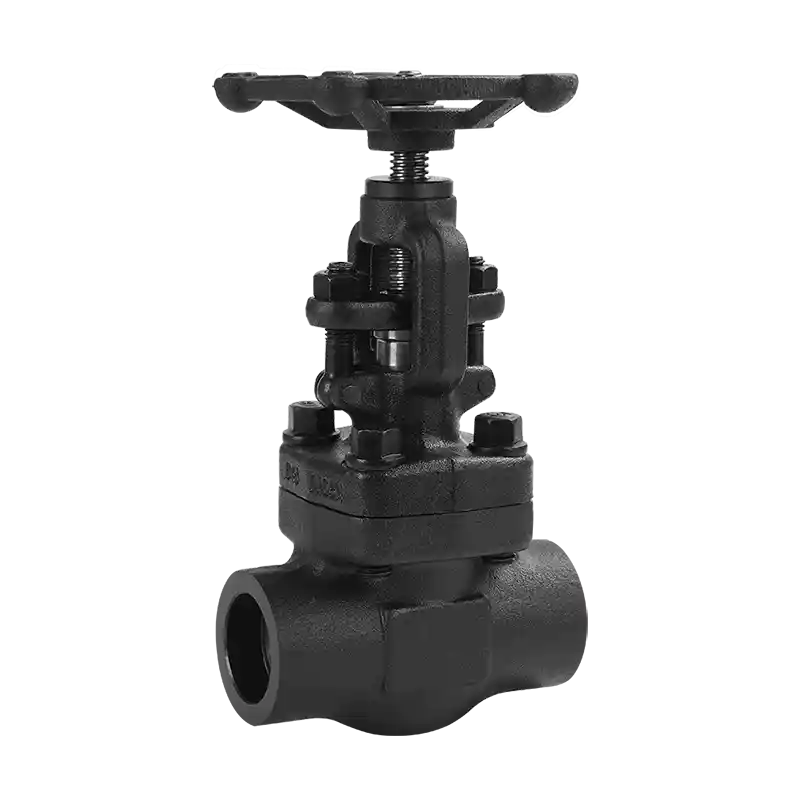

Flanged Forged Steel Globe Valve

The flanged forged steel globe valve is a type of forged steel valve specially designed for high-pressure and high-temperature applications. This valve is manufactured from forged steel. Compared with cast valves, it has higher strength, corrosion resistance and longer service life.

The design of the flanged forged steel globe valve ensures precise throttling and reliable closing, making it an ideal choice for oil, natural gas, petrochemical and power generation systems. The flanged connection facilitates installation and maintenance, enabling efficient operation even in harsh industrial environments. Deco forged steel globe valves combine material durability and precise control to ensure safe and efficient operation in pipeline systems worldwide.

Structural Features

Torque range: 15 N·m to 400 N·m;

Forged valve body structure: Manufactured from forged steel to enhance strength, density and impact resistance;

Metal hard-sealed valve disc and seat are coated with Stellite alloy or tungsten carbide (WC), featuring high-temperature wear resistance (suitable for ≤650°C);

Optional soft seal: PTFE or graphite packing for low-temperature clean media (water, air, etc.), achieving Class VI bubble tight seal;

Eliminates sand holes/porosities, suitable for high-pressure and high-vibration applications.

Technical Parameters

Nominal Diameter: DN15-DN50, 1/2"-2"

Nominal Pressure: 150LB-1500LB

Applicable Media: Water, oil, steam, etc.

Applicable Temperature: -20°C-550°C

Valve Body Material: A105, Stainless Steel

Connection Mode: Flanged Connection

Design Standards: BS 5352, MSS SP-118

Manufacturing Standard: GB/T 12235-2007

Flange Standards: JIS B2220, ANSI B16.5, GB/T9113

Structural Length: JIS B2002, ANSI B16.10, GB/T 12221