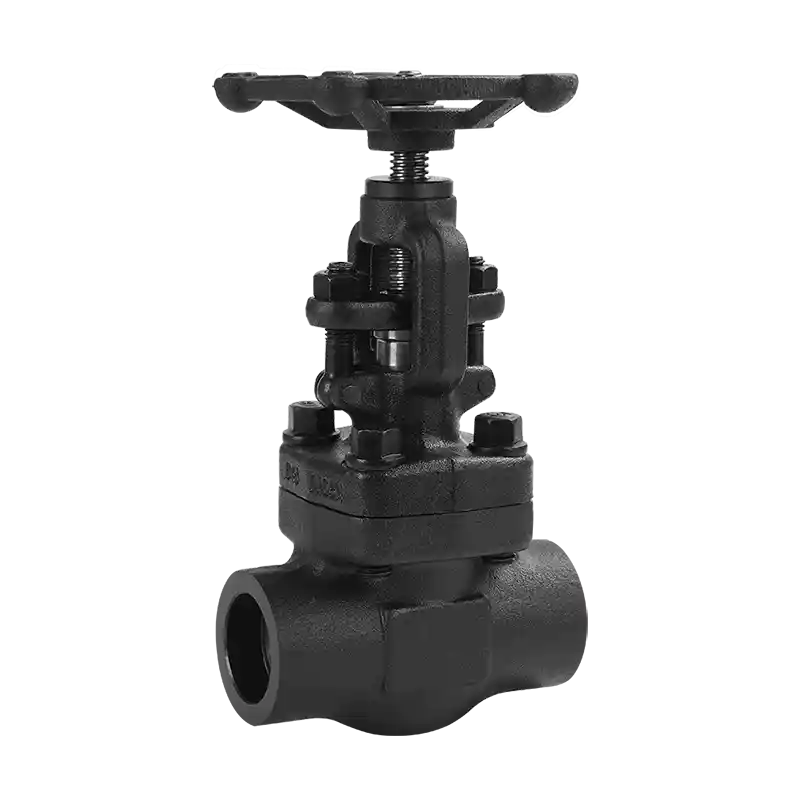

Forged Steel Bellows Sealed Globe Valve

The key component of the Forged Steel Bellows Sealed Globe Valve is the metal bellows. Its lower end is connected to the valve stem assembly by automatic roll welding, and the upper end is connected to the connecting plate by automatic roll welding, forming a metal barrier between the fluid medium and the atmosphere to ensure zero leakage of the valve stem. It is widely used in petrochemical, chemical fiber textile, plastic papermaking, electric power and steel, printing and dyeing rubber, natural gas and other gases, with safe and reliable performance, and is also widely used in industrial fluids such as ethylene glycol. The bellows seal design eliminates the shortcomings of ordinary valves such as fast valve stem aging and easy leakage. It not only improves energy efficiency, enhances the safety of production equipment, reduces maintenance and frequent upkeep, but also provides a clean and safe working environment.

Product Features

Excellent Sealing Performance: The bellows globe valve adopts a bellows seal design, which completely eliminates the shortcomings of fast aging and easy leakage of the valve stem packing seal of ordinary valves, and can ensure zero leakage of the valve stem.

Long Service Life: The bellows has a long fatigue life, and all parts are made of high-quality materials, with wear resistance and corrosion resistance. It can reduce the maintenance frequency and is suitable for frequent opening and closing scenarios.

Easy Operation: The handwheel adopts an ergonomic design, with a longer service life and easy operation. There is no lifting handwheel and position indicators ("+" "-"), making the operation more intuitive. At the same time, the bonnet is equipped with a lock nut, which can fix the valve opening at a certain position.

High Temperature and High Pressure Resistance: It has a wide operating temperature range, such as -196℃~560℃, and a large pressure range, such as 150~2500LB, suitable for various high-temperature, high-pressure and impact working conditions.

Wide Range of Applicable Media: It can be used in pipelines for steam, flammable, explosive, heat transfer oil, high-purity, toxic and other media, meeting the various working condition requirements of petroleum, chemical, pharmaceutical, chemical fertilizer, electric power and other industries.

Compact and Reasonable Structure: Compact structure, small flow resistance, space-saving and easy installation.

Technical Parameters

Nominal Diameter: DN15-DN50

Nominal Pressure: 1.6MPa-4.0MPa

Applicable Media: Water, oil, steam, etc.

Applicable Temperature: -196℃~500℃

Valve Body Material: A105, F304, F316, F316L

Connection Type: Flange, Butt Weld, Socket Weld

Design Standard: DIN 3352, GB/T 122234-2007

Face-to-Face Dimension: DIN 3202, GB/T 12221-2005

Connecting Flange: DIN 2543-2545, HG/T 20592-97

Test and Inspection: DIN 3230, JB/T 9092-99