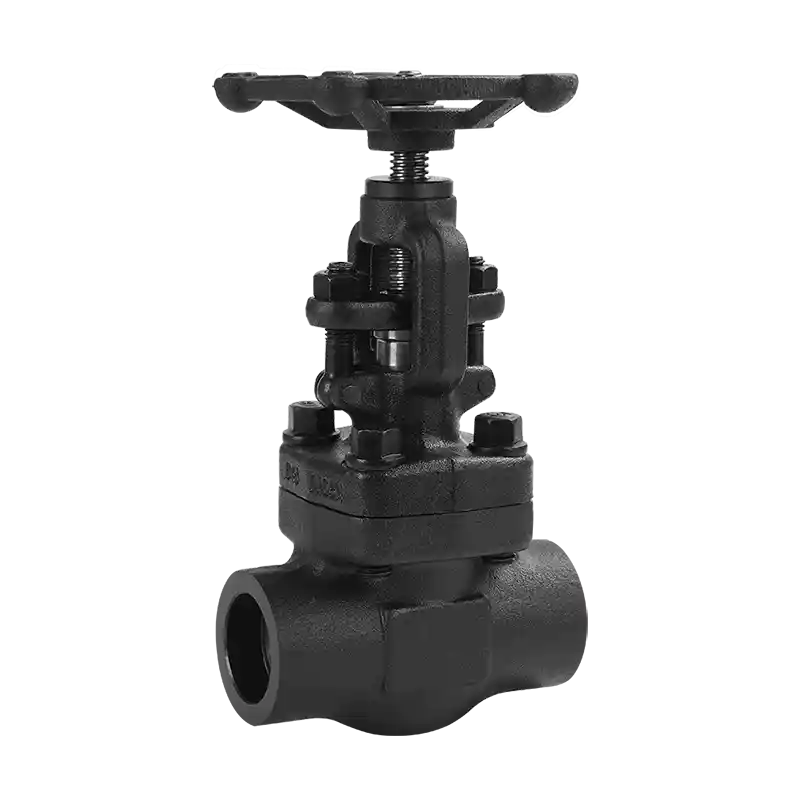

Forged Steel Y-Strainer

The Forged Steel Y-Strainer features threaded, flange, butt weld, or socket weld connections, with all main components made of forged materials and forgings produced through forging processes. Forged steel parts offer higher quality than cast steel parts, capable of withstanding large impact forces, high temperatures, and high pressures. Their plasticity, toughness, and other mechanical properties are also superior to those of cast steel Y-Strainers. Therefore, Forged Steel Y-Strainers are widely used as filtering equipment in important machinery and equipment, as well as in critical and complex working conditions. This product eliminates external leakage caused by transportation collisions and casting sand holes.

The Forged Steel Y-Strainer adopts a bolt-on bonnet design. For valves designed in this form, the valve body and bonnet are connected by bolts, with sealing achieved through spiral wound gaskets (made of 304 stainless steel plus flexible graphite) or metal ring joints.

Features of Forged Steel Y-Strainer

Full port or reduced port.

Socket ends comply with ASME B16.11.

Bolted bonnet with spiral wound gasket sealing.

Threaded ends (NPT) comply with ANSI/ASME B1.20.1.

Optional drain plug and replaceable filter screen.

Technical Parameters of Forged Steel Y-Strainer

Nominal Diameter: 1/2"-4“

Nominal Pressure: 150LB-4500LB

Valve Body Material: A105, LF2, F11, F304, F316, F321, etc.

Operation Mode: Manual, Pneumatic, Electric, Hydraulic

Connection Type: Flange, Butt Weld, Socket Weld, Threaded

Applications of Forged Steel Y-Strainer

The Forged Steel Y-Strainer is characterized by a simple structure, low resistance, and convenient sewage discharge. It is usually installed at the inlet end of various devices and equipment to remove impurities in the medium, thereby protecting valves and equipment for normal use. The Forged Steel Y-Strainer adopts a bolt-on bonnet design, where the valve body and bonnet are connected by bolts, sealed with spiral wound gaskets (made of 304 stainless steel plus flexible graphite) or metal ring joints. The standard filter screen for water applications is 18-30 mesh/inch, and custom filter screens are available upon customer request.