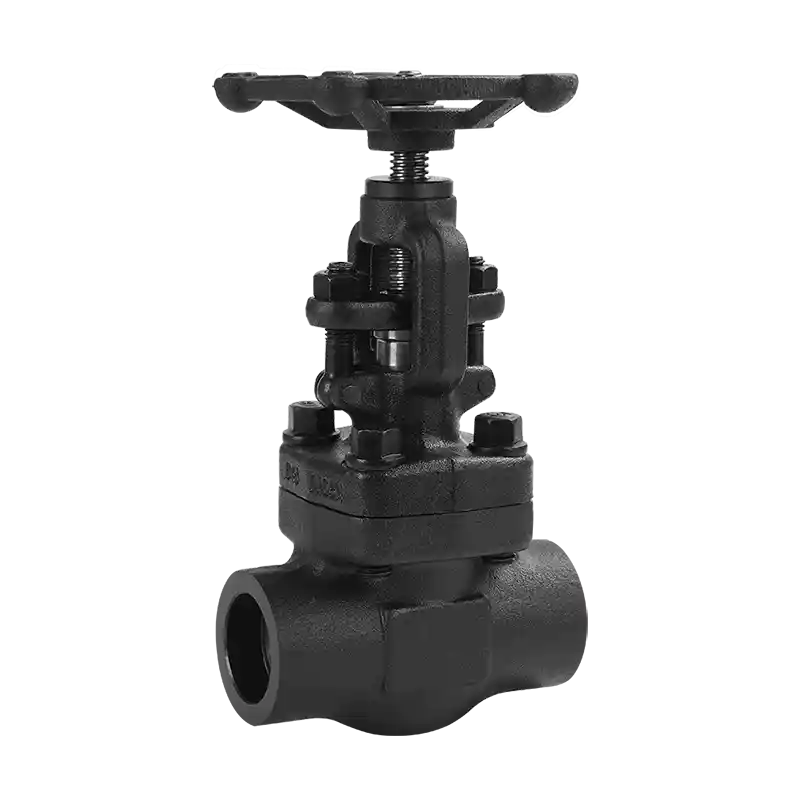

Forged Steel Y-Type Globe Valve

The valve body and bonnet of the Forged Steel Y-Type Globe Valve are integrally forged, featuring high strength, attractive appearance and reliable material quality. The middle cavity adopts a self-sealing structure; the higher the pressure, the better the sealing performance. The unique stainless steel self-sealing ring enables convenient disassembly and assembly as well as reliable sealing. The surface of the valve stem is subjected to super dense wear-resistant treatment, which provides wear resistance and corrosion resistance, reduces opening and closing friction, and ensures no external leakage of the product.

Structural Features of Forged Steel Y-Type Globe Valve

The pressure self-sealing Forged Steel Y-Type Globe Valve and Check Valve comply with ANSI B16.34. Inspection and testing are in accordance with API 598, and marking is in accordance with MSS-SP-25;

Adopts the following structures;

Full port or reduced port;

Lift type and ball type Check Valve;

Built-in spring as required;

Removable solid valve disc;

Self-centering pressure plate and sleeve type;

Integral upper sealing seat;

Outside Screw & Yoke (OS&Y) type;

Bolted bonnet with spiral wound gasket sealing, threaded bonnet with full-weld sealing, and threaded bonnet with internal pressure self-sealing;

Socket ends comply with ASME B16.11;

Threaded ends (NPT) comply with ANSI/ASME B1.20.1;

The valve disc can be converted into needle type, throttling type, ball type and check type.

Technical Parameters of Forged Steel Y-Type Globe Valve

Valve Body Material: Forged Steel, Stainless Steel, Duplex Steel, Alloy Steel, etc.

Nominal Diameter: DN25~DN250 (1"~10")

Nominal Pressure: PN16~PN76 Mpa (Class900~4500)

Operating Temperature: -20℃~400℃

Driving Mode: Bevel Gear, Electric, Pneumatic

Sealing Material: Stainless Steel, Cemented Carbide, etc.

Valve Core Material: Forged Steel, Stainless Steel, Duplex Steel, Alloy Steel, etc.