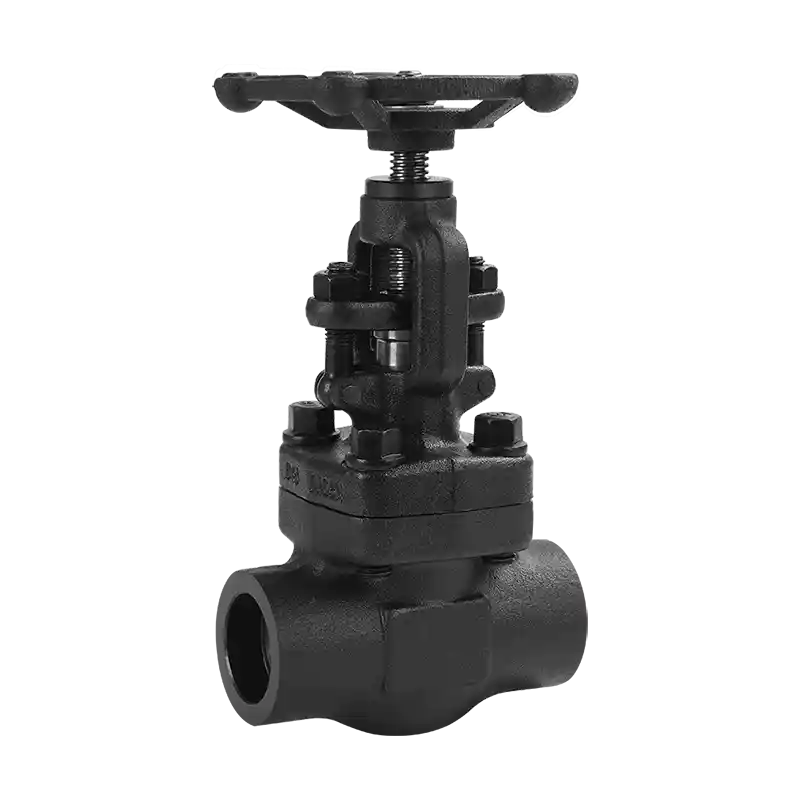

Forged steel bellows sealed gate valve

Forged steel bellows sealed gate valves feature a more uniform structure, higher density, superior strength integrity, better dimensional characteristics and smaller dimensional tolerance in comparison with cast valve bodies. The directional forging structure delivers higher overall performance in terms of strength and stress resistance than castings.

Technical Parameters of Forged Steel Bellows Sealed Gate Valve

Nominal Diameter: DN15-DN50

Nominal Pressure: 1.6MPa-10.0MPa

Applicable Medium: Water, Steam, Oil

Applicable Temperature: -20℃-425℃

Valve Body Material: Carbon Steel, Stainless Steel

Connection Mode: Flange, Welding

Design Standard: DIN3352, GB/T12234-2007

Connecting Flange Standard: DIN 2543-2545, HG/T20592-97

Structural Length Standard: DIN 3202, GB/T12221-2005

Features of Forged Steel Bellows Sealed Gate Valve

The metal bellows, as the core component of the bellows sealed gate valve, is automatically roll-welded with the valve stem assembly at its lower end and the connecting plate at its upper end. It forms a metal barrier between the fluid medium and the atmosphere, ensuring zero leakage of the valve stem.

Dual sealing design (bellows + packing). In case of bellows failure, the valve stem packing can still prevent leakage, complying with international sealing standards.

The valve bonnet is equipped with a built-in grease fitting, which can directly lubricate the valve stem, nut and shaft sleeve, different from the traditional way that only lubricates the screw thread.

The handwheel is designed with ergonomics, featuring longer service life, easy and convenient operation, as well as higher safety and reliability.