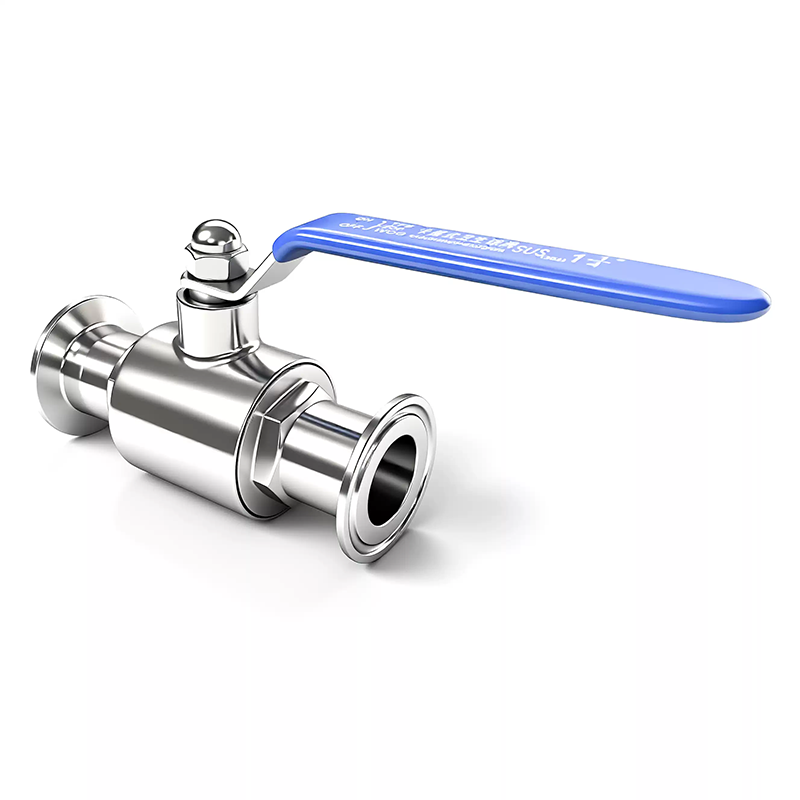

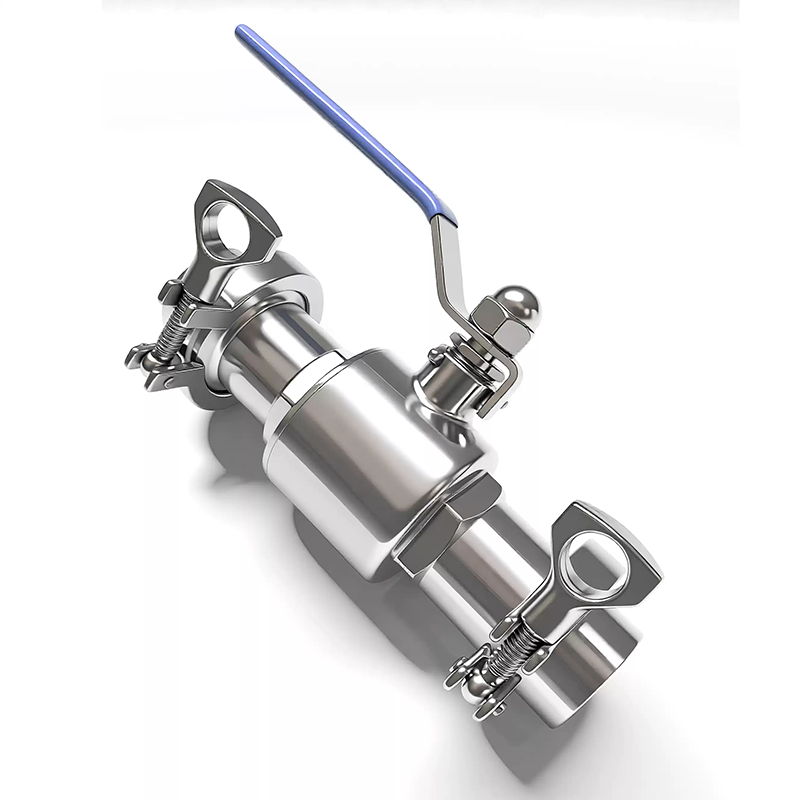

Sanitary Ball Valves with Clamp Ends

Sanitary Ball Valves with Clamp Ends - Overview & Technical Parameters

The interior and exterior of the Sanitary Ball Valves with Clamp Ends are processed with polishing equipment, meeting the requirements of surface mirror polishing. It is used in food, beverage, dairy products, beer and chemical industries.

Technical Parameters of Sanitary Ball Valves with Clamp Ends

Standard: DIN, SMS, ISO, IDF, 3A, RJT, DS, BS, BPE, API, JIS, GB

Material: CF3M, SUS316L

Valve Seat: PTFE/PTFE + 15% Glass Fiber

Surface Finish: Internal Surface (Mirror Polishing)

Sealing Ring: Ball Pad - PTFE; Central Shaft - EPDM and PTFE

Packaging: Carton/Wooden Case/Shockproof Film

Working Pressure: 0~1.5Mpa

Working Temperature: -10℃~+150℃ (High-temperature ball valves can be customized)

Application Scope: Suitable for food, brewing, beverage, dairy products, chemical, biological engineering and other industries

Shell Material: Stainless Steel 304, 304L, 316, 316L

Description: The stainless steel sanitary ball valve is made of 316L. Its fully enclosed internal structure prevents residue accumulation, thus meeting the requirements of media in food and biological fields and complying with the standards of the hygiene and food industry.